Composite tidal turbine to harness ocean energy

Glass, carbon composites are the materials of choice for system that harvests energy from tidal currents.

The use of turbine technology to generate electric power from natural forces is far from new. Since the 1930s, turbines inside dams on river systems around the world have converted the kinetic energy of water currents into the mechanical energy necessary to drive huge generators that supply affordable electrical power to a significant segment of electrical utility customers. In the last 20 years, the same has been done with wind currents, as wind turbine technologies have become practical and cost-competitive, in large part through the use of composites to make rotor blades and other components. But today, composites are a key feature of a potential third wave of turbine technology that may soon tap what is an almost undeveloped but potentially vast energy source, ocean currents.

The potential for electrical energy generation from ocean currents dwarfs today's production from hydroelectric dams. If its flow capacity were tapped to the same extent as the Hoover Dam taps the Colorado River, the Atlantic Ocean's Gulf Stream alone could provide 20 times today's U.S. electricity demand. The potential mechanical energy latent in tidal flows is enormous and, unlike oil and coal resources, endlessly renewable. Moreover, since the density of water is some 832 times greater than the density of air, an ocean current of only 2.3 m/sec (4.5 knots), such as that found in the Gulf Stream, can produce electricity at a rate equivalent to a 62.5 m/sec (140-mph) wind. In addition, studies of a variety of tidal turbine designs have concluded that the environmental impact of these turbines on sea flora and fauna is negligible and that they satisfy governmental regulations for artificial sea structures.

Given the similarities between aerodynamics and hydrodynamics, the Aircraft Design and Aeroflight Dynamics Group (ADAG), part of the Department of Aeronautical Engineering at the University of Naples, Italy has become a noted pioneer of tidal turbine technology. Since 2001, a pilot tidal turbine plant called ENERMAR has been moored in Italy's Strait of Messina about 150m/490 ft offshore in waters 18m to 25m (59 ft to 82 ft) deep, moored with four 350 kN concrete anchoring blocks and 70-mm/2.8-inch chains. Funded by the Ponte di Archimede Co. (Messina, Italy), the plant produces 25 kW of electrical energy from a marine current of only 2 m/s (4 knots), using an ADAG adaptation of the internationally patented Kobold turbine. With one success in the water, ADAG's Prof. Domenico Coiro and his design team are already at work on a second-generation turbine prototype, the MYTHOS.

ENERMAR's "global efficiency," measured by the ratio of produced power to theoretical power available in the current, is about 23 percent — comparable to today's wind-turbine efficiency but capable of improvement, says Coiro. The MYTHOS turbine is expected to improve on ENERMAR's performance, potentially achieving 30 percent global efficiency. Much of the increase will be the result of ADAG's continuing work on rotor hydrodynamics.

Ocean Optimization

This task has been formidable. The increased loading that water puts on a turbine makes blade strength and stiffness more critical than they are in wind turbine blades. In fact, neither wind-turbine designs nor standard hydroelectric dam turbines can simply be submerged into an ocean current. Add to that the fact that tidal turbines will necessarily be placed in more remote locations — positioned, for instance, 15m (nearly 50 ft) or more underwater or suspended from an anchored buoy several kilometers offshore — and turbine weight, methods of construction and installation, and maintenance/repair strategies become critical considerations.

As they have in wind turbines, composites are playing a key role in tidal turbine design. The high loading on the blades -- 3000 kgf/m² (614.5 lbf/ft²) for a 2.5-m/sec (4.86-knot) current — makes composites an ideal material choice, Coiro says. The composite blades' high rigidity will keep them from bending, which will help minimize hydrodynamic losses. Composites also help keep maintenance costs down. "The weight and buoyancy," Coiro notes, "is such that two divers can disassemble the blades and bring them up on the sea surface."

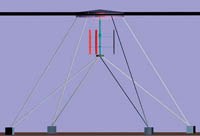

That said, tidal turbine rotors bear little resemblance to their cousins in wind farms. Today's commercial wind turbines typically employ horizontal-axis designs, with blades attached perpendicular to the transmission shaft. ADAG's systems, however, feature a vertical-axis (cross-flow) design, in which the blades and rotor transmission shaft are parallel to one another and are both oriented perpendicular to the incoming current flow. This configuration permits the rotor to rotate in the same direction regardless of marine current direction, an important consideration in the ebb and flow of a tidal environment.

While vertical-axis designs have been attempted in the wind energy market, they've met with little success. One type, the so-called "Darrieus" style, uses curved blades that give the turbine the appearance of an eggbeater. "These normally require an auxiliary starting engine to initiate rotation, which diminishes efficiency," Coiro explains. Furthermore, blade flexure and stiffness are problematic, especially since the great variation in wind speed creates correspondingly large swings in blade loading.

The ADAG blades, therefore, are straight and positioned parallel to the transmission shaft. Support arms attach the blades to the shaft and accommodate blade pitching, such that the angle of the blade as it turns in the current can adjust to the optimal position. The mechanism is a proprietary attachment device that allows the blades to change angle relative to the support arm, to optimize movement through the water. The straight blades experience less flex loading than Darrieus-style blades, and the steady and more predictable tidal currents dramatically decrease load variation. "You know exactly the maximum load that the blades will bear during their life," Coiro notes, "because you know in advance the maximum marine current in the site where the turbine will be installed." While ADAG's original Kobold turbine requires no auxiliary power, the blades must be allowed to partially oscillate (pitch back and forth due to hydrodynamic and inertial forces) around their vertical-axis hinges to start up the turbine. Since then, ADAG researchers have identified a proprietary strategy, related to the blade's airfoil design and the pitching mechanism, that will start MYTHOS without this oscillation, increasing system efficiency.

For their straight blade, researchers initially employed a symmetrical airfoil design that also has been attempted in vertical-axis wind turbines (VAWTs). ADAG tested configurations of two, three, four and six blades. A three-blade design was found to offer the best combination of efficiency and manufacturability.

In water, however, conventional VAWT blades were subject to a common hydrodynamic phenomenon known as cavitation, which occurs when pressure gradients form vapor bubbles on blade surfaces. Repetitive collapse of these bubbles creates unwanted vibration and imparts localized stress that ultimately damages the blades, reducing turbine efficiency. ADAG tried another established symmetrical airfoil that had been designed to be cavitation-free, then modified that design to maximize hydrodynamic efficiency and decrease negative lift, which occurs because the blades follow a circular path through the tidal current. (Just as aircraft wings experience lift as one of the aerodynamic forces acting on them, the turbine blades experience lift as well. Negative lift acts counter to the direction you want the rotor to travel.) As a result, Coiro reports, "We developed a new nonsymmetrical airfoil that, for the first time, has been employed in a vertical-axis turbine, showing better performance than symmetrical airfoils." ADAG's nonsymmetrical design is predicted to be cavitation-free in up to 4-m/sec (8-knot) currents.

The unique, nonsymmetrical contour of the airfoil is easily fabricated with composites. Using epoxy resin with a copper powder additive (to prevent bio-fouling), each 320-kg/704-lb blade will include outer and inner plies of glass fiber (to avoid galvanic corrosion) surrounding a number of layers of woven carbon cloth, including some axial (0°) and some bias plies (±45°). Where the pitching mechanism contacts the blade, some aramid reinforcement also will be used for impact resistance.

The MYTHOS fabrication process will be similar to that used for the ENERMAR blades. In that instance, each weighed about 60 kg/130 lb and was hand layed up and vacuum bagged for room-temperature cure by Speco Srl (Naples, Italy), a fabricator known for its sailing yacht booms and masts. G. Angeloni Srl (Quarto d'Altino, Veneto, Italy) supplied both the carbon fabric, made from T700 intermediate-modulus carbon fiber supplied by Toray Industries (Tokyo, Japan) and the epoxy resin, manufactured by Bakelite AG, now a business unit of Hexion Specialty Chemicals (Columbus, Ohio).

Like the Darrieus turbine, the MYTHOS-type turbine is unlikely to be commercialized in the wind energy market. Drag on the support arms degrades turbine efficiency at typical wind speeds. The relatively small effect of hydrodynamic drag in the comparatively slow ocean currents and ADAG's more efficient blade design make them attractive in marine applications. In addition, ADAG is redesigning the support arms for MYTHOS to further reduce drag.

On the Kobold turbine, the arms were steel beams, rectangular in cross-section, that were subsequently encased in streamlined glass/epoxy fairings, to reduce drag. Although the fairings contribute little additional weight, at 7 kg/15 lb each, and are easily removed to permit inspection of the arms, they required a 0.4m/1.3-ft chord to accommodate the combined thickness of arm and fairing. Moreover, the overall weight of each arm is 187 kg/411 lb. On MYTHOS, therefore, ADAG is likely to replace the steel arms and fairings with hydrodynamically contoured composite arms, probably fiberglass with polyester resin. The arm's reduced thickness and resulting smaller chord will reduce its wetted area (surface area that directly meets the water mass), minimizing drag, says Coiro. Reduced weight also will ease turbine assembly and disassembly. "But the challenge," he cautions, "is to keep the price comparable to steel." On MYTHOS, the only metal remaining in the arm/blade assemblies will be stainless steel structures that form the pivot attachments.

Cost-Effective Energy Source

When built, MYTHOS will be twice the size of the ENERMAR turbine. Its 12m/39.4-ft diameter rotor, with three blades, each 10m/32.8 ft in length with a chord of 0.8m/2.6 ft, will be suspended below a circular 14m/45.9-ft diameter, 3m/9.8-ft tall buoy. The buoy will house an electrical generator and will be moored by eight chains and four anchoring blocks, which will prevent the rotor from tilting and thus losing efficiency. Electrical transmission cables will follow the mooring lines down to the ocean floor.

At about twice the rotor diameter of the ENERMAR system, MYTHOS will yield a maximum power output of 150 kW in a 2 m/sec current, according to computer analysis of the design. Its 30 percent global efficiency is predicted for a wide range of current velocities, from 1 m/sec to 2.5 m/sec (2 knots to 5 knots). Along with improved hydrodynamics, the increased efficiency is due in part to the use of a direct-drive permanent magnet (PM) electric generator. Developed in cooperation with the Division of Electricity – The Angstroem Laboratory at Uppsala University (Sweden), the new design eliminates the gearbox altogether.

In the past decade, entrepreneurial innovators such as Coiro and his team have prototyped at least a half-dozen tidal energy systems. These systems bode well for affordable tidal energy, with predicted commercial costs of $0.04/kWh (USD) or less — beating the typical fossil fuel cost of $0.05/kWh. The MYTHOS system will yield a predicted energy cost of about $0.10/kWh even as a prototype, which translates to a very promising commercial rate.

Related Content

Honda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

Read MoreHexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks

CW attends the opening of Westminster, Maryland, site and shares the company’s history, vision and leading role in H2 storage systems.

Read MoreCollins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreNCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More