Curved pultrusion? No longer an oxymoron

Radius-Pultrusion process offers linear or curved profiles.

Share

Read Next

In the early days of composites manufacturing, the materials for building fiber-reinforced plastic/composite parts were laid into molds by hand. Hand layup is still common in the industry, but automated processes — notably pultrusion, filament winding, automated tape layup (ATL) and others — have been developed along the way to replace or streamline manual operations.

Pultrusion was one of the first automated processes. Patented in 1959 by W. Brandt Goldsworthy (1915-2003), pultrusion is an automated, computer-controlled process for manufacturing linear, constant-cross section, fiber-reinforced composite profile parts quickly, consistently and endlessly, and then reliably cutting them into pre-programmed lengths.

Although early models could process only unidirectional reinforcements, later system designs have enabled the addition of multiaxial fabrics during processing. Typically a thermoset process, pultrusion also has been adapted for composite profiles with thermoplastic matrices.

Historically, pultrusion has been limited in that the profiles it generates are oriented along a linear axis. In a word: straight. But nonlinear pultruded profiles were envisioned almost from the beginning. Goldsworthy and other composite pioneers soon asked, Why can’t we make curved pultrusions?

The earliest curved variant was probably Goldsworthy’s Pulformer, patented and built in the early 1980s by his team as a contender for production of curved thermoset composite leaf springs for the automotive industry. The Pulformer combined step compression molding with pultrusion material infeed technology to enable continuous, automated manufacture of curved parts and parts with non-uniform cross sections. In the end, the technology didn’t fulfill the envisioned potential: Composite leaf springs are found on cars today, but they are molded, mostly by RTM. One automaker in the US and another in Japan bought Pulformers and did considerable research, but no Pulformed leaf springs were installed on production cars. Curved pultrusion technologies conceived by other machinery manufacturers were similarly unable to attain commercial success.

Nearly four decades later, however, Thomas Technik & Innovation (TTI), part of Thomas Holding (Bremervörde, Lower Saxony, Germany), is reporting considerable success with its version of curved pultrusion technology, developed in part with financial support from the European Union and Lower Saxony.

Notably, TTI’s principal business focus is healthy sleep: Since 1957, it has invested in research, development and production of beds for homes, hospitals, rehabilitation and care facilities, and mobile applications in trucks and recreational vehicles. Two decades ago, that led to composites production — using carbon and glass fiber, and more recently natural fiber-reinforced polymer composites — initially to improve the comfort of its bedding systems. One of its core composite competencies, as a result, is pultrusion.

Rethinking the stationary die

Trademarked Radius-Pultrusion, the company’s curve-capable technology operates like conventional linear pultrusion, but with some important differences, as explained by Klaus Jansen, CEO of TTI.

Conventional pultrusion uses a reciprocating pulling system to draw dry fibers through a resin chamber, then through a heated forming/curing tool (die), and then into an automated cutoff saw. The key here is that the part profile is cured as it is pulled through a stationary die. A constant cross-section, linear profile is continuously produced by this system.

“In the Radius-Pultrusion process,” Jansen explains, “the heated die tool is no longer stationary but works as the upstream, and only moving, stage of its pulling system. The heated die tool is a reciprocating puller, and a stationary gripper on the downstream end of the line opens and closes as programmed, but does not travel. The die tool grips incoming raw material at the upstream end of the line, then moves downstream, curing the profile as it proceeds toward the gripper unit. As the die moves downstream, the gripper remains open and the cured profile is pushed through it, toward the automated cutoff saw. When the die reaches the downstream gripper, the gripper closes, firmly holding the cured profile while the die opens and again moves upstream to pull and cure the next section of material. This essential difference — a moving die — allows the material to be pulled around a curve. The result is a system that can continuously produce either a linear constant cross section or a constantly curved profile,” Jansen says.

As with conventional linear pultrusion, Radius-Pultrusion is a wet process. The fibrous materials are wet-out either by resin injection or in an open bath where local environmental regulations permit.

TTI has vetted its system with a variety of composite materials, including glass or carbon fiber impregnated with vinyl ester, epoxy, polyurethane, acrylate esters and others. Multiaxial fabrics are commonly incorporated, as well as veils, which are especially useful for helping drape the material in the mold, Jansen says. What is needed in reinforcements for Radius-Pultrusion is material suited for what Jansen calls endless draping, to enable the material to follow the curve. “It must be flexible,” Jansen says, noting that many woven materials are, indeed, flexible enough to be pulled around the curve.

Five degrees of freedom

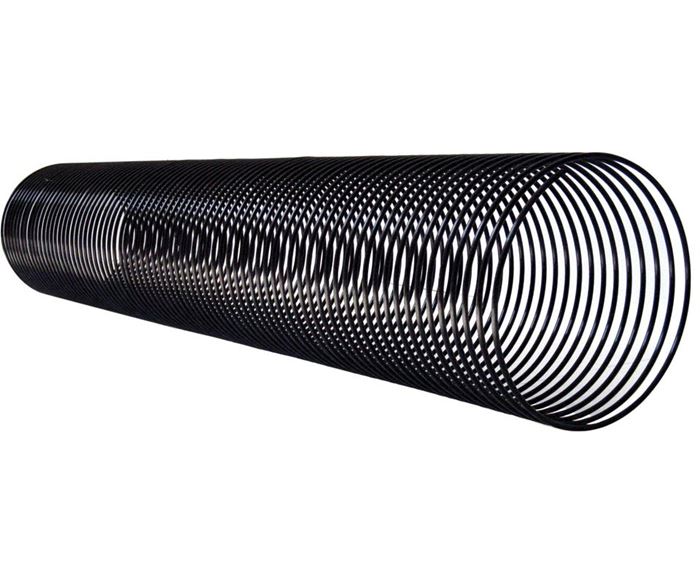

For a constant curve in space, at least five degrees of freedom are necessary. “In addition to the horizontal x-axis of linear pultrusion, curved pultrusion needs up to four additional axes,” Jansen explains, naming the vertical y-axis, transversal z-axis and rotational axes (clockwise and counterclockwise), which would be added, for example, to make pipe (Fig. 1).

Jansen says TTI is now building machines that can produce linear profiles and — with some modification — curved parts with radii greater than 2,000 mm), incorporating the required additional axes of freedom. “Where the radius is parallel to the long axis, rotation and linear movement is vertical; and where the radius is parallel to the short axis, rotation and linear movement is horizontal,” Jansen says. Typical parts, where the radius is parallel to the long axis, are bumper beams that are created with a vertical orientation of curve. Parts that can better be created with a horizontal curve include the thin reinforcement profiles for glass roofs on cars.

For smaller-sized curved parts, with radii less than 2,000 mm, a different, custom design is offered. For these, the machine rotates about a central axis, which may be either horizontal or vertical. Parts for bicycle wheel rims are one example of what is possible on this type of machine. TTI, in fact, is in discussion with and making proof-of-concept carbon epoxy rim components for a bicycle manufacturer interested in the potential of Radius-Pultrusion. The part radius here is about 300 mm.

“Every kind of profile that is somehow curved can be manufactured by pultrusion now,” says Jansen.

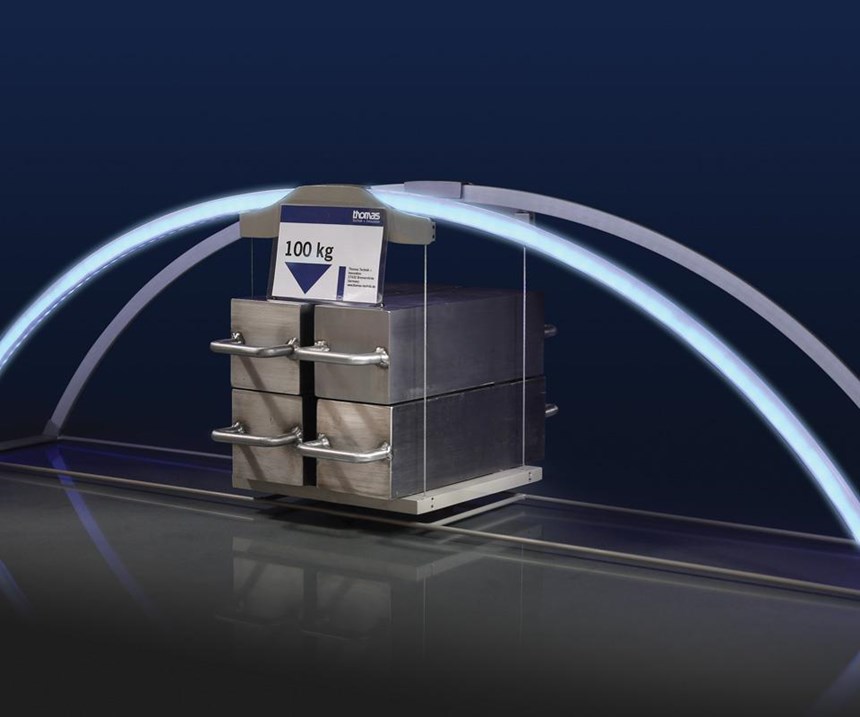

Licensing the process

In addition to producing parts for customers on its Radius- Pultrusion machines, TTI is licensing the technology to others. “We are currently developing new pultrusion lines together with KraussMaffei Technologies in Munich, Germany, one of the biggest European injection molding and reaction technology manufacturers,” Jansen reports. “Complete lines, especially for fast or demanding resins, such as polyurethane, epoxy and reactive polyamide, are under development and will be sold through KraussMaffei, using the Radius-Pultrusion pulling units and controls from TTI, with the possibility for the customers to license the technology for curved profiles” (Fig. 2).

TTI also has a partner in Japan that is selling the machinery there, Jansen says, adding that he is not authorized to identify the company or product, but says the parts might be for infrastructure elements. “They won’t tell us,” Jansen says. “Nearly every company that has visited us expressed considerable interest and often asked for certain profiles for evaluation — without identifying the use for these profiles. They only tell us the specifications for the profile they want” (e.g., Figs. 3 and 4).

Another major licensing agreement TTI has recently signed, and one it can discuss, is with Shape Corp. (Grand Haven, MI, US). Although it is a global supplier of multiple material structural components, primarily in the automotive sector, Shape also sells to a diversified group of customers in other markets, says John Keene, Shape’s marketing communications lead.

The agreement calls for TTI to supply its Radius-Pultrusion machines and technology to Shape to enable manufacture of automotive bumper beams (Fig. 5). Jansen expects the first machine will be operational this year. “During the last year, Shape and Thomas Technik formed a real partnership for the development of a new generation of automotive profiles, and we are looking forward to future joint-development projects,” Jansen says. “The ability of Radius-Pultrusion to manufacture curved and hollow profiles is a perfect fit to both our strategies to bring new technologies to the customer.”

Today, most composite automotive bumpers are non-load-bearing injection or compression molded thermoplastics. Thermoset bumper beams are less common because they are weightier and more brittle than comparable thermoplastic bumpers. Steel beams are still the most widely used because of their low cost, but compared to composites, they add weight to the vehicle and leave the part corrosion-prone. Further, those who use steel sacrifice opportunities for parts consolidation in manufacturing. This also results in less energy absorption during a crash, thus reducing passenger protection.

Toby Jacobson, Shape’s plastic materials and process manager/advanced product development, adds that Shape chose TTI’s Radius-Pultrusion process primarily for its automation, increased speed and ability to produce tubular and multiple hollow cross sections.

Jacobson identifies the material systems Shape chose following extensive trials to develop a laminate architecture and resin formulation that best works with Radius-Pultrusion: “While the process provides the flexibility to run nearly any type of thermoset resin, our resin of choice is polyurethane,” he says. “It offers exceptional toughness properties at reasonable cost while allowing us to achieve some very fast production rates. For reinforcements, we are running unidirectional, biaxial and triaxial noncrimp [stitched nonwoven] fabrics. We’re also pulling some individual unidirectional tows when necessary. While most of the current interest is with carbon fiber, this process will excel with fiberglass and a variety of other reinforcements.”

Keene adds, “This combination of extensive process and product design research, paired with production trials and physical testing, has Shape in position to install their first curved pultrusion machine in 2017, in preparation for 2019 model year production.”

Curves make the difference in cars and more

Historically, linear pultrusion has not stimulated much interest in the automotive industry because there are simply very few long, straight beams in passenger cars. Almost all automotive parts are curved. Given that reality, curved pultrusion offers the opportunity to open some doors.“The ability to reliably pultrude a constant curvature could result in replacing steel in a number of applications,” says Michael Connolly, program manager for Urethane Composites at Huntsman Polyurethanes (Auburn Hills, MI, US). He names bumper beams, roof beams, front-end support systems, door intrusion beams, chassis rails and, perhaps, transmission tunnels as potential curved pultruded car parts. “Pultrusion is efficient, in that it is automated, low-labor and low-capital, compared to other composite processing equipment,” Connolly sums up, “and can have a low scrap rate compared to RTM and other molding processes. I think the automotive community will start to see pultrusion as something they might be able to exploit, now that curved pultrusion may be available and reliable.”

Such systems — proven reliable and capable of commercial series production — could make a substantial difference in a wide range of other market applications as well. Potential output includes bicycle parts, as well as a host of curved shapes unique to infrastructure, architecture and building construction. In time, a wide variety of curved parts now made in individual molds might be produced continuously by curved pultrusion.

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More