CW Top Shops 2023: Honoring global top-performing facilities

CW congratulates the 2023 CW Top Shops honorees and composites fabricators whose leaders cite team expansion, focus on Industry 4.0 and adaptation to emerging markets among this year’s top achievements.

The CompositesWorld team is excited to share this year’s CW Top Shops honorees.

Each year, CW, in collaboration with Gardner Intelligence, invites composites fabricators globally to participate in the CW Top Shops benchmarking program. This involves submitting a detailed survey regarding a facility’s operations over the past year, which Gardner Intelligence then uses to create customized benchmarking reports for each participating company. These reports illustrate a facility’s performance in a variety of metrics — such as capacity utilization, scrap rate, lead times and more— in comparison with others that have taken the survey. Facilities that perform highly across metrics qualify for the honorable distinction of CW Top Shop.

Congratulations to this year’s qualifying Top Shops:

- Bucci Composites S.p.A. (Faenza, Italy)

- Champion Fiberglass (Spring, Texas, U.S.)

- Cobra International Co. Ltd. (Chonburi, Thailand)

- Compotech Inc. (Brewer, Maine, U.S.)

- EPP Composites Pvt. Ltd. (Rajkot, India)

- GSE Dynamics Inc. (Hauppauge, N.Y., U.S.)

- Phoenix Composite Solutions (Oscoda, Mich., U.S.)

- Refisa Composite Structures (Lleida, Spain)

- Sarins Båtar ab (Kokkola, Finland)

- Tata Advanced Materials Ltd. (Jigani, India)

What makes a Top Shop?

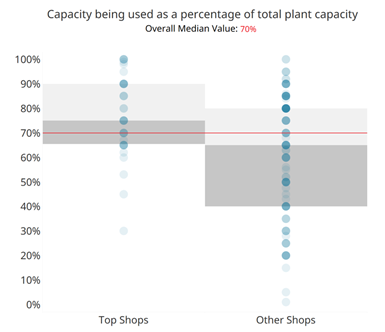

High-performing facilities. Companies achieving the “Top Shop” distinction are those that achieve higher performance across a variety of measured metrics through the annual benchmarking survey. This year, high capacity utilization and uptime are two metrics that Gardner Intelligence’s Jan Schafer says make Top Shops stand out from other facilities. Photo Credit: Gardner Intelligence

What makes the 2023 CW Top Shops stand out? Jan Schafer, director of market research at Gardner Intelligence, explains that “Top Shops, by definition, perform at higher levels than ‘other’ shops on multiple metrics. Looking at this year’s data, one metric on which CW Top Shops and other shops have diverged in a pretty big way for the past two years is capacity utilization. A related metric, uptime, shows a parallel relationship.”

Beyond the data, representatives from several of this year’s Top Shops explain how their facilities have grown and achieved new goals in the past year.

New market applications. Bucci Composites’ Bedeschi says that one of the company’s biggest achievements this year has been the development of new, 20-inch carbon fiber composite sports car rims (pictured). Photo Credit: Bucci Composites

For example, Bucci Composites, an Italy-based, two-time CW Top Shops honoree specializing in structural and aesthetic automotive components, emphasizes higher production rates and new applications. Andrea Bedeschi, general manager at Bucci Composites, says, “The results over the past year have been quite significant. First, we started the production phase of an automotive hood with production rates of 30 components per day. Few companies in Europe (maybe even worldwide) can achieve these production rates for such a sophisticated component. As a second major milestone, we have completed development and are starting the sale of 20-inch carbon fiber rims for sports cars. This is the second rim we’re bringing to market after the 22-inch wheel we’re producing for the OEM Bentley.”

Agile production. Cobra International credits this year’s successes to an adaptable team, shown here producing a variety of watersports products. Photo Credit: Cobra International

Cobra International, a Thailand-based company with a core business in high-quality composite watersports products, recognizes adaptability in a changing market as one of its key strengths. “I would say that the last year has required a massive degree of adaptability on our part,” Danu Chotikapanich, CEO, reports. “The post-pandemic period has seen some major demand shifts in our watersports composites markets, and we have needed to remain extremely agile and efficient in our production and supply chain processes as we respond to our customers’ requirements. This period has also given us a chance to focus on some of our growing markets, with composites for drones and marine components being two areas of recent expansion.”

He adds that adding new certifications is also an area of focus for the facility. “2023 was a big year for the company in terms of new certifications, with ISO 14001 Environmental and ISO 45001 OHS systems being added to our existing ISO 9001 and IATF 16949 scope audited by TÜV Nord. We continue to work with our customers to ensure that our product quality exceeds their expectations and maintain our internal focus on our ambitious sustainability improvement targets.”

Industrial manufacturing. EPP Composites’ facility, pictured, manufactures FRP pipe and various equipment for chemical and industrial plants, as well as building and construction products. Photo Credit: EPP Composites

EPP Composites, an India-based company specializing in composite industrial components like pipes, chemical plant equipment and construction applications, commends its increased efforts toward Industry 4.0. Jayraj Shah, managing director, explains, “Thirty-seven years of dedication to work for the promotion and growth of fiber-reinforced plastics for better living has shaped us into a multi-dimensional action center with the concept to commissioning a business model. Ever-growing customer expectations have been the driver of our growth. During the past year, we have focused our external and internal infrastructure on aligning with recommendations of Consumer 4.0/Industry 4.0/Marketing 4.0.”

Increasing capacity. Compotech Inc. notes that this year has seen increased facility and team size, adding to the company’s capabilities. Compotech also emphasizes AI, machine learning and robotics in its defense manufacturing operations (pictured). Photo Credit: Compotech Inc.

Compotech is another company that has earned the Top Shops distinction two years in a row. Based in Maine, it specializes in composites-based solutions for the defense market. President Paul Melrose emphasizes the company’s growth both in production and in its team: “Over the past year, Compotech has nearly doubled its manufacturing capacity through increasing the size of the facility and more than doubling the size of the team,” Melrose says. “Our ability to grow and scale the business while attracting capable employees has been a major strength, and key to our success.”

The utility of Top Shops data

Beyond the honor of being recognized as a CW Top Shop, what is the utility of the benchmarking data?

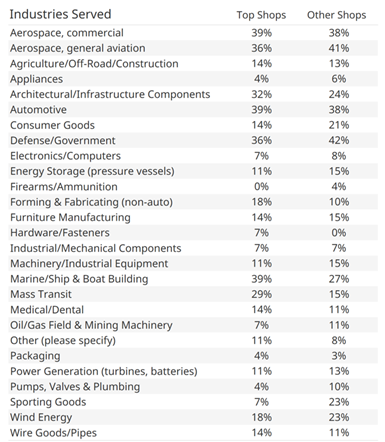

Industries served. Top Shops and other facilities who participated in this year’s survey serve a range of end markets, from commercial aerospace to wind energy and pipes. Photo Credit: Gardner Intelligence

“Time and again we hear that Top Shops benchmarking data is not just nice to know, but useful,” Gardner Intelligence’s Schafer says. “Reporting the distribution of individual responses show ‘how high is up.’ That bar may not be within reach for a given shop currently, but it can serve as a stretch goal. For near-term goals, clusters of values in the distribution of responses indicate performance levels many shops have achieved. It is reasonable for a shop performing below that level to set a target in that range. Having a database for setting performance goals helps rally the organization, thereby increasing the odds of achieving them. Bottom line, participating shops can get a lot of mileage out of Top Shops!”

Compotech’s Melrose agrees. “The benchmarking report is very helpful in forming key performance indicators [KPI] for our company, and it enables Compotech to gauge how we are performing compared to other composites shops,” he notes. “We use the benchmarking report to continually improve the business with the goal of ensuring that Compotech remains one of the top composites shops in the world.”

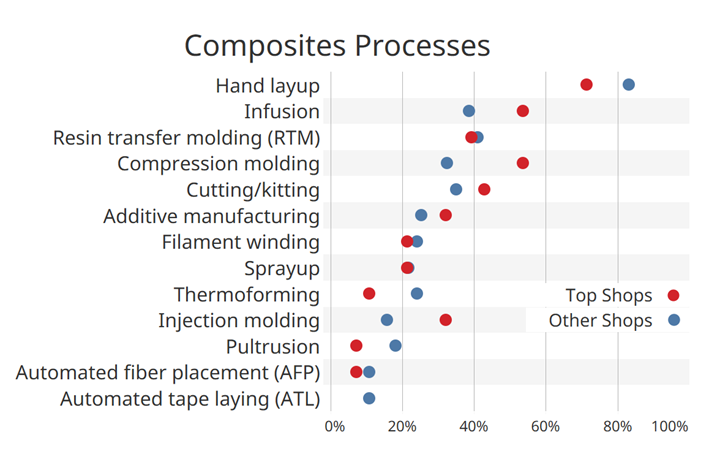

Representing a range of processes. This year’s responses show a variety of processes used by surveyed companies, including hand layup, infusion and compression molding. Photo Credit: Gardner Intelligence

EPP Composites’ Shah adds, “We at EPP have been able to inculcate the concepts down the line and have made significant changes. The net result has been customer benefits in quality and product pricing.”

The CW team extends its congratulations to this year’s CW Top Shops, and thanks all companies participating in the program. In the coming months, keep an eye out for continued coverage of this year’s qualifying Top Shops as we continue to get to know these top-performers.

Interested in getting your facility involved? Look for the 2024 CW Top Shops link at the beginning of the year.

Related Content

Industrial equipment manufacturer expands global footprint, reaches into new markets

India-based CW Top Shops honoree EPP Composites reflects on a recently successful vertical filament winding application and new pultruded FRP rebar capabilities, as well as future opportunities.

Read MoreCompositesWorld reveals 2024 Top Shops benchmarking survey results

CW recognizes the qualifying composites fabricators in its 2024 Top Shops program and highlights some of the survey's general findings.

Read MoreBallistic protection panels manufacturer relies on automation for high throughput, efficiency

Maine-based CW Top Shops honoree Compotech Inc. recently doubled its manufacturing space and team to produce modular composite panels for defense applications via light resin transfer molding (LRTM).

Read MoreDefense manufacturer reflects on growth, opportunity in complex composite structures

Long Island-based, four-time CW Top Shops honoree GSE Dynamics cites diversification in processes, digitalization, workforce training and more on its successes over 50+ years, and looks ahead to future growth.

Read MoreRead Next

CW Top Shops 2022: Recognizing composites industry leaders

The highest-performing facilities from the 2022 CW Top Shops benchmarking survey share insights about business growth, overcoming labor shortages, sustainability best practices and more.

Read More2020 CW Top Shops recognizes top-performing facilities

CW's second annual Top Shops benchmarking survey helps composites fabricators put their operations into perspective and illuminates top-ranking facilities.

Read More2021 CW Top Shops highlights strengths of top composites facilities

CW learned from some of this year’s designated Top Shops about what makes facilities stand out, from diverse capabilities to Industry 4.0 and sustainability.

Read More

.jpg;width=70;height=70;mode=crop)