CompositesWorld, in cooperation with Gardner Intelligence, launched its second annual CW Top Shops benchmarking survey this year (see more on our 2019 Top Shops here). The survey, promoted earlier in 2020 , asks composites fabricating facilities to submit data in many areas related to their operations, including order lead time, machine uptime, capacity utilization, wages, customer retention, sales growth, labor turnover, scrap rate, materials and processes used, inspection technologies and machinery employed, supply chain and marketing practices, certifications and more.

The 98 composites fabricators that participated this year came from around the world representing every major end market, including aerospace, automotive, marine, energy, consumer and industrial (Fig. 1). Participating companies were provided with a customized report putting their data in perspective with others that took the survey. Each facility was then ranked for each metric, giving us an overall ranking for each facility. The top 31 facilities earned this year’s Top Shops label.

Fig. 1: Industries Served |

||

|---|---|---|

|

|

Top Shops |

Other Shops |

| Aerospace, Commercial | 41% | 51% |

| Aerospace, General | 28% | 36% |

| Agriculture | 13% | 8% |

| Automotive | 25% | 19% |

| Construction/Infrastructure | 38% | 26% |

| Consumer | 19% | 17% |

| Defense/Military | 44% | 43% |

| Industrial/Corrosion Resistance | 22% | 21% |

| Marine | 28% | 26% |

| Mass Transit | 16% | 8% |

| Medical | 19% | 11% |

| Oil and Gas | 25% | 8% |

| Sports and Recreation | 34% | 26% |

| Wind Energy | 16% | 13% |

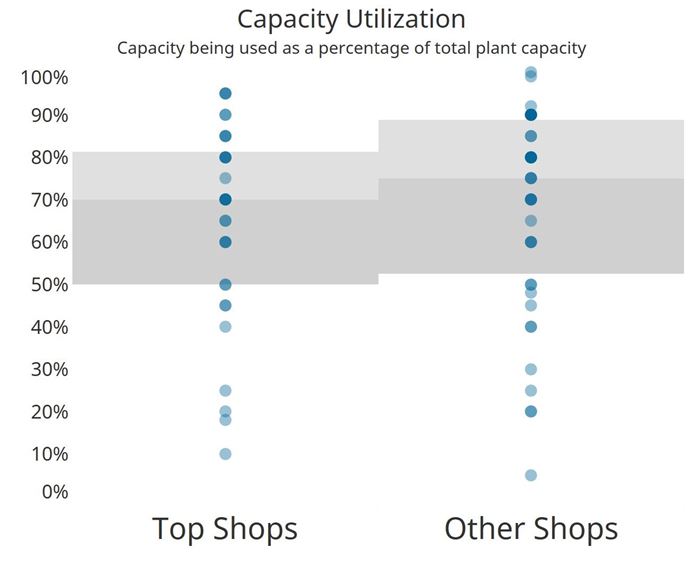

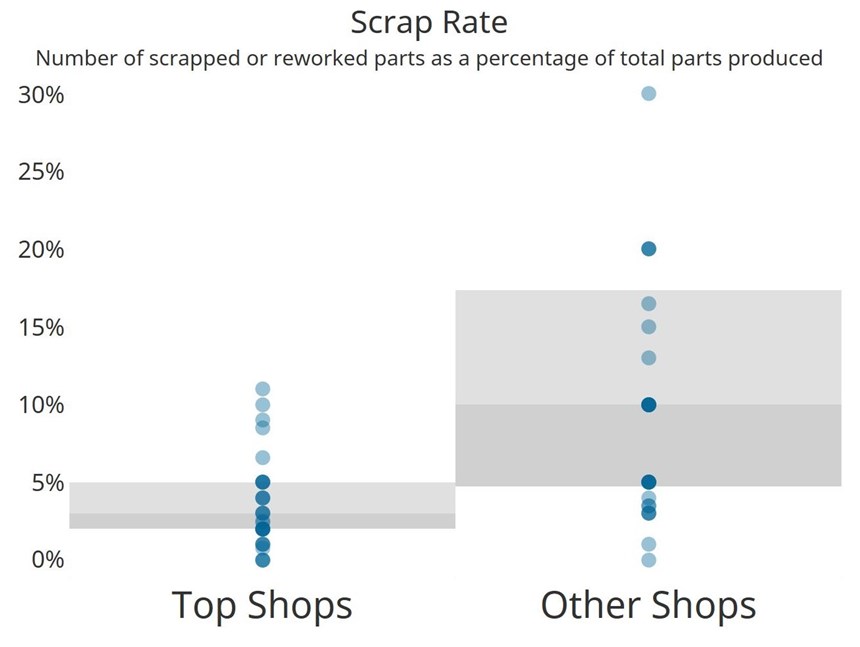

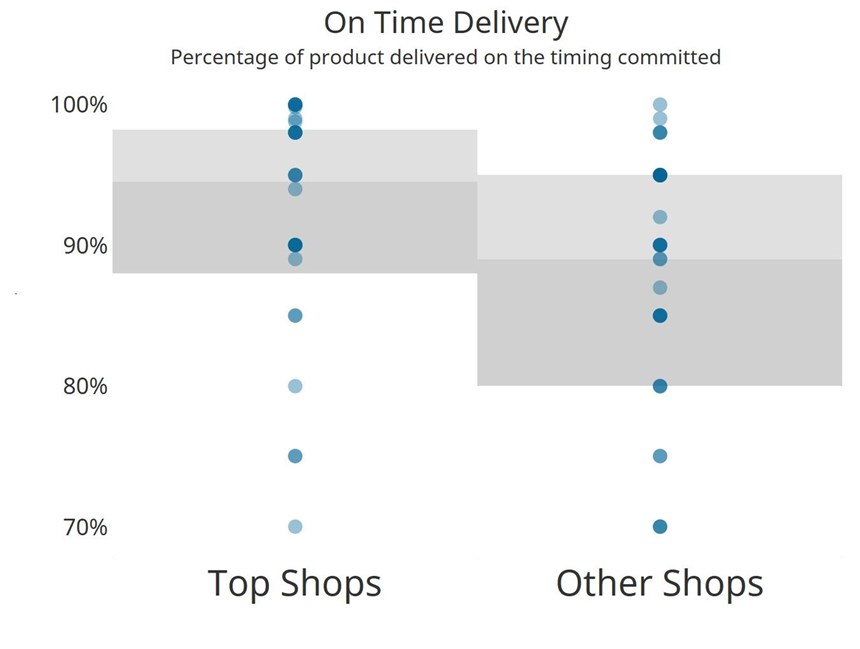

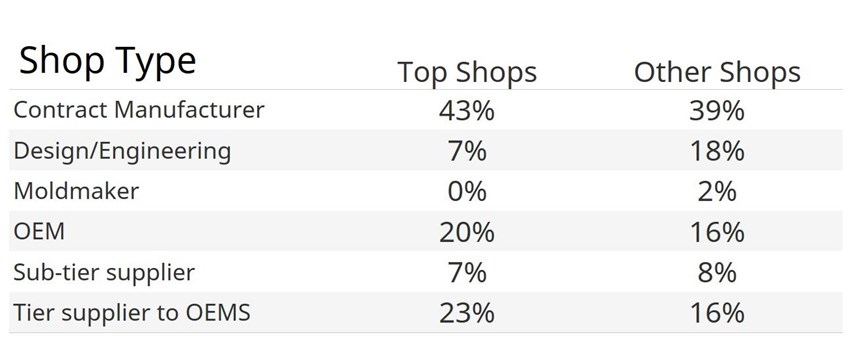

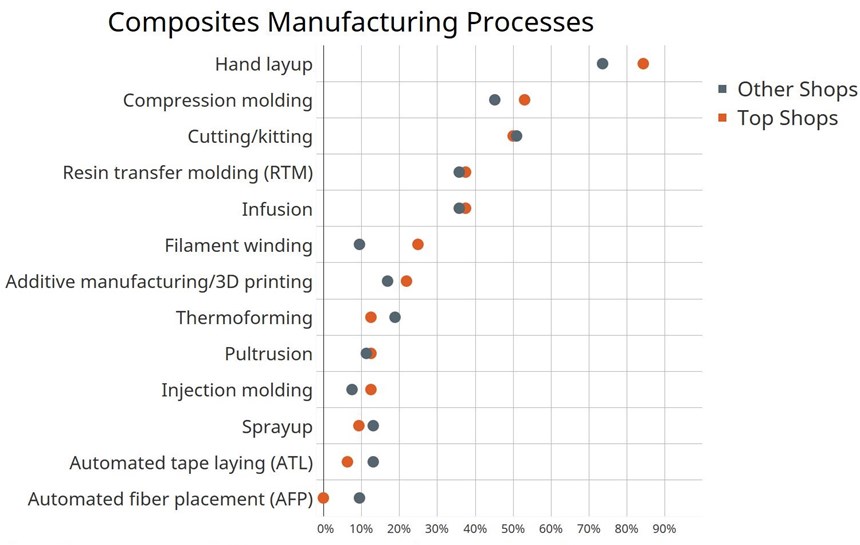

Facilities that participate in the CW Top Shops survey receive the full report for free. However, if your facility did not participate, and if you would like to see the full results, you can purchase the CompositesWorld Benchmarking Standards Report at the Gardner Intelligence website. As a sample of the data we collected, the figures in this report aggregate the responses for this year’s participants in several areas: capacity utilization (Fig. 2), scrap rate (Fig. 3) and on-time deliveries (Fig. 4), as well as shop type (Fig. 5) and manufacturing processes used (Fig. 6).

Fig. 2-6

This year’s Top Shops

The top-ranking facilities across all response areas earn distinction as CW Top Shops (Fig. 7), and we are proud to announce the 2020 recipients. This year, CW had the opportunity to speak with representatives from several of these companies to learn more about what they do. What follows is a summary of a few of these conversations.

Fig. 7: 2020 CW Top Shops winners |

|||

|---|---|---|---|

Company |

City |

State/Province |

Country |

| Advanced Thermoplastic Composites LLC | Post Fall | Idaho | U.S. |

| Airbus Defense and Space | Madrid | Spain | |

| Amalga Composites Inc. | West Allis | Wis. | U.S. |

| Atech Composites Co. Ltd. | Kaohsiung | Taiwan | |

| AVMATS | Manchester | Mo. | U.S. |

| Carbon Marine | Mississauga | Ontario | Canada |

| Carborundum Universal Ltd. | Chennai | Tamil Nadu | India |

| Carlson Commercial & Industrial Services Ltd. | Winnipeg | Manitoba | Canada |

| Champion Fiberglass | Spring | Texas | U.S. |

| Competition Composites Inc. | Arnprior | Ontario | Canada |

| Composite Resources | Rock Hill | S.C. | U.S. |

| Compoxi SL | Girona | Spain | |

| ETM Enterprises Inc. | Grand Ledge | Mich. | U.S. |

| Flying S Inc. | Palestine | Ill. | U.S. |

| GKN Aerospace | Muenchen | Bavaria | Germany |

| GSE Composites Inc. | Hauppage | N.Y. | U.S. |

| Ingenium LLC | Reno | Nev. | U.S. |

| Innovative Composite Engineering | White Salmon | Wash. | U.S. |

| Janicki Industries | Sedro-Wooley | Wash. | U.S. |

| Lingol Corp. | Wallingford | Conn. | U.S. |

| Meridian Kayak | Tolmie | Victoria | Australia |

| Orenco Systems Inc. | Sutherlin | Ore. | U.S. |

| Osborne Industries | Osborne | Kan. | U.S. |

| Plasan Carbon Composites | Walker | Mich. | U.S. |

| Pocock Racing Shells | Everett | Wash. | U.S. |

| Prodrive Composites Ltd. | Milton Keynes | Buckinghamshire | U.K. |

| Sicamb | Latina | Latina | Italy |

| Southwest Composite Works | Albuquerque | N.M. | U.S. |

| Spartec Composites Inc. | Erin | Ontario | Canada |

| The Gund Co. Inc. | Saint Louis | Mo. | U.S. |

| Tiger Composites Inc. | New Smyrna Beach | Fla. | U.S. |

Champion Fiberglass (Spring, Texas, U.S.) was founded in 1988 by president Goran Haag and a business partner. Combining their backgrounds in chemical and electrical engineering, the partners started with old equipment from a local conduit manufacturing facility and began making fiberglass composite conduit and pipes that serve the electrical, infrastructure, chemical manufacturing and wastewater treatment industries. “It really is a classic niche market,” Haag says. “A lot of conduit is made with PVC or steel, so we’re just a fraction of that market, but we’re growing … today, we’re the largest fiberglass conduit manufacturer in North America.”

Currently, the company operates in an approximately 120,000-square-foot facility with 125 employees. A year and a half ago, Haag adds, the company doubled its previous output with the addition of a third production line. The company’s primary process is filament winding, but it also produces conduit boxes and other related parts via compression molding. Champion Fiberglass builds all of its molds at its in-house machine shop, with plans to build an additional 100 molds over the next five years. Haag adds that automation and a new process for manufacturing bridge drains and struts are also on the near horizon. “Our company slogan is ‘Do more,’” Haag says. “We really try to go the extra mile on everything.”

Competition Composites Inc. (CCI, Arnprior, Canada) was founded in 2002 primarily to develop foils for recreational sailboats. According to Philip Locker, president of CCI, since then the company has grown to its current 12 employees and 20,000-square-foot facility, where its focus has shifted to provide a range of solutions including wind blades for renewable energy, composite shelters for the Canadian government and radomes for the communications industry.

Along with its staple boat rudders, Competition Composites Inc. also fabricates parts for a variety of industries, such as composite panels for shelters. Photo Credit: Competition Composites Inc.

About 30% of Competition Composites’ annual business still comes from composite rudders, Locker says. “We have a solid product line that’s our bread and butter, but we do an increasing amount of contract work that spans many types of product areas.”

The rudders are built from carbon and/or glass fiber and epoxy, using mostly hand layup and vacuum bagging. The company makes a lot of vacuum-infused flat panels for a variety of industries, including glass fiber composite sandwich panels for shelters. Two 3-axis CNC milling machines and a more recently acquired 5-axis machine enable the creation of more tooling and larger projects, Locker says.

“One of our strengths is that we have a very good handle on our processes and costs,” he adds. “For the past few years, we’ve done online, cloud-based time sheets for all of our staff, for example. We know exactly how long each of our processes and projects takes and we’re able to connect that data directly with costs and transparency for the customer. We’re also an ISO 9001-0215 qualified facility, and Controlled Goods certified — a government designation here in Canada. We’re about as efficient as we can be, and we apply a lot of value to our customer. We try to hit the right value points and offer a range of services. We work with our customers to pick the right processes and applications for them — not every project needs vacuum bagging or autoclave cure.”

Operating since 2007, Compoxi (Girona, Spain) currently operates an almost 13,000-square-foot facility, including workshop and office space, with 16 employees and plans for growth. “We describe ourselves as an engineering firm with a capacity for production,” says Marc Gascons, managing director, noting that, until 2018, the company was solely a small-volume production facility, but in the last two years it has grown its engineering and design services as well. Compoxi can produce parts directly, design and engineer new parts from scratch, or provide what Gascons calls “co-engineering,” which is a middle-ground service that enables customers to split engineering responsibilities with Compoxi. “We have a very flexible, skilled team that provides engineering designs for composite materials, and we combine that with very skilled production,” Gascons says.

Approximately 60% of Compoxi’s business comes from the space and aeronautics markets, Gascons says, growing out of work the company did early on for the commercial aerospace industry. “Many companies start in industrial markets and then grow in quality in processes until they enter the aerospace market,” Gascons says, “but we were born the other way around.” Starting from building test coupons for Airbus, Compoxi began to translate its skills into end-use aerospace and space parts, and transitioned to other industries from there. “The fact that we grew directly from the aerospace industry puts our skill and quality levels at a very high standard,” Gascons says.

Today, about 40% of Compoxi’s business comes from other end markets including wind energy, medical devices, industrial applications and automotive. Gascons adds that diversity in end markets is a key to success, especially in the pandemic-era economy. “We are getting engaged in bigger programs in different markets, and the fact that we are balanced in different markets will be the key for survival and growth in the coming years. You can see through the pandemic how fragile a company can be if it relies on only one sector of the industry.”

Most of Compoxi’s work is done with carbon fiber/epoxy prepreg, with parts manufactured via hand layup and autoclave cure. The company also has experience with RTM, infusion and other materials such as glass fiber and other resins, especially in wind energy applications.

Founded in 1989, Innovative Composite Engineering (ICE, White Salmon, Wash., U.S.) employs a workforce of about 70 people at its 65,000-square-foot facility near the Columbia River Gorge in Washington. The company offers composite solutions from prototype to mass production — and everything in between, according to Rob Warwick, sales manager.

Part layup at ICE's facility. Photo Credit: Innovative Composites Engineering

ICE uses internally developed rolling and fiber placement processes to produce tube-shaped composite structures, Warwick says, and also offers services for complex molded structures through bladder and compression molding. Almost all of its work is done with prepreg materials, and ICE serves a range of markets: aerospace, space, defense, automotive, marine, industrial, oil and gas and recreation.

“ICE is a group of engineers running a manufacturing facility. We love challenges and are not afraid to roll our sleeves up in the pursuit of perfection,” Warwick says. “Everyone gets involved in tackling composite solutions for our customers.”

He adds that ICE puts value in designing, building, modifying and constantly improving its process machines “to do what no one else can. We want to show the world that ‘good enough’ is never good enough,” he says.

Southwest Composite Works (Albuquerque, N.M., U.S.) was founded in 1994 as a tooling and metal casting company, especially for composites fabricators, says John Groth, president and owner. “We consider ourselves to be masters of shape,” he notes, “so about 10 years ago it became a natural transition to go from tooling for composites to manufacturing composites ourselves as well.” He adds that composite materials allow the company to engineer products in new ways. “There’s not an engineer that graduates from MIT who dreams of building things out of metal these days. They want to build things out of advanced materials like composites.”

With 10 employees, Southwest Composite Works recently moved to a new 15,000-square-foot facility — its largest yet to accommodate an expanding composites business, Groth says. Compression molding and fiber forging are the company’s core processes, dovetailing the capabilities on the tooling side of the business. Groth adds that Southwest can also do RTM and infusion. The company’s main core business is recreation, with customers in all areas of the sporting goods market.

“Our strength is our business culture,” Groth says. “We’ve got a strong team where everyone is genuinely invested in what they’re making. We’re all about relationships — with our customers, our vendors and our staff.”

CW Top Shops 2021

Congratulations to all of this year’s Top Shops, and thank you to all who participated. Keep an eye out for the 2021 CW Top Shops survey, which will launch in January. An announcement will be posted on our website and distributed through the CW Today e-newsletter — or, you can send a note to CW Editor-in-Chief Jeff Sloan at jeff@compositesworld.com to get on the distribution list.

Related Content

Industrial equipment manufacturer expands global footprint, reaches into new markets

India-based CW Top Shops honoree EPP Composites reflects on a recently successful vertical filament winding application and new pultruded FRP rebar capabilities, as well as future opportunities.

Read MoreCompositesWorld reveals 2024 Top Shops benchmarking survey results

CW recognizes the qualifying composites fabricators in its 2024 Top Shops program and highlights some of the survey's general findings.

Read MoreFiberglass conduit manufacturer grows into new products, infrastructure applications

Texas-based Champion Fiberglass, a five-time CW Top Shops honoree, expands its success in the fiberglass composite conduit market into new applications and products, looking toward future automation and sustainability initiatives.

Read MoreBallistic protection panels manufacturer relies on automation for high throughput, efficiency

Maine-based CW Top Shops honoree Compotech Inc. recently doubled its manufacturing space and team to produce modular composite panels for defense applications via light resin transfer molding (LRTM).

Read MoreRead Next

CW's Top Shops puts operations in perspective

The inaugural CW Top Shops benchmarking survey is designed to help composites fabricators understand how efficient their manufacturing operations are.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;width=70;height=70;mode=crop)