CW's top 10 digital content of 2017

CW’s first list of 2018 is a simple one: The top 10 most viewed articles on the CompositesWorld website in 2017.

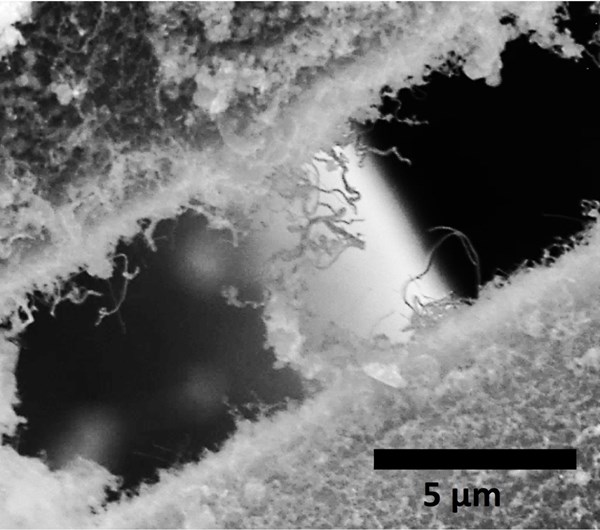

SiC “fuzz” grown from carbon nanotubes onto SiC fibers provide strong interlocking connections that may boost damage tolerance for SiC-based CMCs.

From CW’s #1 story of 2017, on ceramic matrix composites.

SOURCE: Rice University, Ajayan Research Group.

Happy 2018, CompositesWorlders!

It’s early January, the holidays are behind us, and it’s time to generate some lists. And CW’s first list of 2018 is a simple one: The top 10 most viewed articles on the CompositesWorld website in 2017. I am sure the suspense is more than you can tolerate, so let’s get right to it. Happy reading.

CompositesWorld’s Top 10 of 2017

-

Blog: The next generation of ceramic matrix composites

New developments in the search for higher-temperature and more damage-tolerant CMCs. -

Blog: Compression molding: New materials and markets

From multifunctional aircraft interiors to compounds using continuous fabrics to the growing use of recycled carbon fiber – compression molding offers new opportunities. -

News: Revolutionary fuselage concept unveiled by MTorres

Paradigm-changing monocoque composite fuselage made without fasteners or molds and with carbon fiber that could cut raw material cost by 50%. -

Blog: SpaceX announces COPV’s role in September rocket explosion

Buckles (voids) between carbon composite overwrap and aluminum liner in cryotank led to ignition of super chilled oxygen — will be fixed long-term via COPV design change. -

Print article: JEC World 2017 exhibit preview

JEC World was held March 14-16, 2017, in Paris. CW previewed some of the products and technologies that were at the show. -

Print article: Plant Tour: GE Aviation, Asheville, NC, US

An avant-garde approach to unprecedented CMC parts production. -

Blog: Superbeam: Steel and carbon fiber work together to revolutionize structural elements

New approach to CFRP-strengthened steel beams increases load capacity by >75%, enabling dramatic downsizing while maintaining traditional bolted and welded attachments. -

Blog: Automated preforming: The numbers and landscape

CW’s multi-blog series on preforming begins with an overview and quick look at the numbers: 1-min takt time, 10-15 seconds per layer, 490-kg/hr and 3.5 million parts/yr. Are you ready for serial CFRP production? -

Blog: Composites recycling is gaining traction

Although CW’s coverage of composites recycling dates back over a decade, informal statistics still show that only ~2% of composites-related companies are active recyclers. That said, three years since our most recent feature on the subject, there is demonstrably greater interest and activity, and real applications of recycled fiber are growing. - Blog: JEC World 2017: Show report, part 1

JEC World 2017 was, by almost any measure, the biggest and busiest JEC event yet, and exhibitors came with much to show the world of composites about innovation in materials, equipment and technology.

Thank you for reading CW, and have a great 2018.

Related Content

-

Composites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

-

CirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

-

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.