Demonstration software modeling exercise aids Taiwan’s yachtbuilding community

Ray Tsai, technical director of Simutech Solution Corp. (Taipei, Taiwan) and colleagues develop a demonstration modeling exercise for Taiwanese motoryacht builders.

Well known for its electronics expertise, Taiwan also maintains a respected luxury motoryacht industry. In 1987, the country exported 1,755 vessels, worth more than $190 million (USD), and today, postrecession, it reportedly has the sixth-largest yachtbuilding community in the world.

To advance its boatbuilding expertise, the country is constructing a dedicated yachtbuilding precinct as part of the Kaohsiung Port City Reconstruction project. Ray Tsai, technical director of Simutech Solution Corp.(Taipei, Taiwan), a Dassault Systèmes (Waltham, Mass.) partner and an expert in the latter’s SIMULIA application, says that despite the island’s standing in the motoryacht market, its yachtbuilders lacked expertise in CAD/CAE and composite layup optimization, particularly for carbon fiber composites.

“Many yacht companies weren’t familiar with computer tools and traditionally outsourced the upfront design to foreign partners,” says Tsai. Together with colleagues Rey-Yie Fong of Tiny Machine and Mechanics Laboratory (TiMMeL, National Taiwan University), and Chia-Chuan O and Yu-Chieh Lin, both deputy engineers with the Ship and Ocean Industries R&D Center, also in Taipei, Tsai developed a demonstration modeling exercise to show builders that SIMULIA enables design iterations far earlier in the development cycle and traces problems during every stage of the pre-production process. “We wanted to help them move iterating cycles from the manufacturing stage to the design stage so that the performance criteria could be evaluated earlier, when it costs much less to modify,” he explains.

Fong chose three elements of yacht design that challenge Taiwanese manufacturers: composite layup architecture; ventilation and thermal analysis; and wave-impact transient analysis. “Designers, manufacturers and customers were struggling with how to achieve the optimal intrinsic strength and stiffness in their designs along with cabin ventilation efficiency, and navigating the tradeoffs around static structure performance and dynamic wave-slamming impact,” says Tsai.

The SIMULIA application portfolio, based on Abaqus finite element analysis (FEA), and Dassault Systèmes’ Simulayt simulation software were tapped for layup analysis and manufacturing process management. Abaqus CFD (computation fluid dynamics) came into play for ventilation and thermal analysis. Abaqus/Explicit was used for Coupled Eulerian-Lagrangian (CEL) analysis, which is central to slamming impact simulation. The CAD tool was Dassault Systèmes’ CATIA, which Fong says seamlessly integrated with all three CAE functions for the demonstration. He chose a 70-ft Monte Carlo-type yacht (photo, top left, p. 69) as a simulation benchmark because it is the median size for Taiwan’s yacht industry, and it conforms fairly closely to the proprietary specifications of most manufacturers.

Tsai says the team was able to import geometry from CATIA and use Simulayt with the composite modeler for Abaqus (CMA) to analyze composite layups. The same models were reused for the CFD simulation, and material properties and conditions could be shared between models without duplication. CATIA Composites came into play at the detailed design stage, helping to optimize design for manufacturability, and it also generated the composite layup geometry, which could then be assigned to Abaqus with specified material properties and fiber orientation. An interface connects CATIA Composite and Abaqus CMA with automatic data transfer, eliminating the possibility of typos and tedious layer-by-layer property assignments. The Simulayt tool then simulated the forces on a composite structure during manufacturing, rounding out the analysis by predicting plant floor fabrication issues, such as hogging loads during hull lifting and demoldings, that can be mitigated earlier in the development cycle. This makes it easier to meet production timeframes within budget.

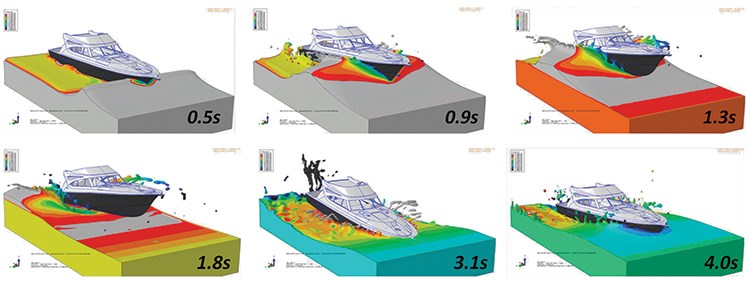

In terms of slam loads and wave impacts (see images, top right), the team used Abaqus CEL to simulate the yacht’s transient and nonlinear varying response to these conditions in straight runs and turning maneuvers. Slamming contact pressure on the hull also was output to determine structure loading under transient impact.

Concludes Tsai, “More widespread use of these advanced simulation methodologies will help Taiwanese yachtmakers. Simulation can help them innovate designs faster while keeping costs in check.”

Related Content

Improving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreComposite sidewall cover expands options for fire-safe rail components

R&D project by CG Rail explores use of carbon fiber-reinforced thermoplastics and recycled manufacturing scrap to meet fire safety, weight and volume targets.

Read MoreNine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More