Designing SHM systems

SHM systems must be designed properly, including self-diagnostic ability to ensure they function as designed.

Structural health monitoring (SHM) systems are entering service. Nondestructive testing (NDT) sensors integrated into commercial and military aircraft structures are enabling periodic or continuous monitoring of damage initiation and growth without the expense and time required to take the structures out of service, disassemble them and perform manual inspections. CW here looks at SHM system design, cost and durability as well as monitoring alternatives via the two most mature systems — Comparative Vacuum Monitoring (CVM) developed by Structural Monitoring Systems (SMS, Nedlands, Australia; Century City, CA, US and Ashford, UK) and an acousto-ultrasonics (AU) technology called SMART Layer developed by Acellent Technologies (Sunnyvale, CA, US).

Technology primer

CVM sensors detect crack initiation and growth by monitoring the slightest pressure change between 0.64-mm channels or “galleries” laser-etched into a Teflon pad. The sensor pads are shape-customized and adhere to structures using self-stick adhesive, and are situated so that mechanics can plug in from a convenient location to acquire the required data. Although some surface preparation is required to achieve a very tight seal, the sensors can reportedly be applied to an easily accessed, fairly smooth surface in 10-15 minutes. Vacuum tubes are then routed to a testing socket and attached using snap-clip connectors like those used in landline telephones. During inspections, a handheld scanning unit is plugged into these testing sockets to interrogate the sensors and give a clear pass or fail indication. When the system interrogates the sensors, a pressure transducer is activated to detect the tiniest flow of air, which typically indicates damage.

SMART Layer sensors comprise polyimide films in which piezoelectric sensors are strategically distributed to communicate with each other by sending and receiving ultrasonic surface waves (Lamb waves). These provide damage assessment based on software analysis of the signal disruptions and changes in patterns vs. baseline data. Sensors are easily installed using aerospace-grade adhesives. When a handheld Scan Genie diagnostic unit is plugged into SMART Layer sockets, it can indicate the damage location and size or simply display a red/green signal to signify damage/no damage in the structure. The system also can be designed to connect to onboard diagnostic units for on-demand or automated interrogation.

Designing the SHM system

“We begin by asking our customers to provide a CAD drawing or model, from which we develop a digital mockup,” explains Acellent Technologies executive VP of business Amrita Kumar. “We then use that to create a sensor layout.” Once the layout is approved, manufacturing of the sensors can begin, which is typically done on a per-project basis because the sensors are incorporated into layers with customized shapes. “One of the issues is to design the layout to avoid areas where sensors aren’t allowed, for example ‘keep out zones’ along the fuselage, or where two structures interfere with each other,” says Kumar. “You cannot just place the sensors anywhere. If you don’t put them in the right place, you won’t be able to detect the damage to the resolution you desire.”

“The question is whether the SHM application is a local or global one,” says SMS director Andrew Chilcott. “For a local application, like a couple of spots around a door, we can design a system that senses five spots via one socket, or else, a system with five different test sockets. It depends on what the engineers want to know and what resolution of crack, disbond, delamination and/or propagation detection they require.” He notes there also might be access challenges that help to decide number of sockets. The desired detection resolution is achieved through the spacing of the galleries (i.e., the pitch between the etched grooves).

Note that both CVM and SMART Layer sensors have been designed to be incorporated into composite structures during manufacture. For SMART Layers, the polyimide films with embedded sensors are simply co-cured into the laminate or bonded onto the surface of the structure. For CVM, the sensor grooves are etched into the laminate and then a Teflon manifold is placed over the top to provide a sealed pneumatic interface.

“For global applications, like along the length of a fuselage or wing stringer,” Chilcott explains, “you would unroll a linear Teflon pad along the structure’s length, on top of grooves laser-machined or molded into the stringer.” He adds that alignment of the galleries is required, but that is well within the capabilities of the automated layup and machining workcells already used to produce these types of CFRP components. “This shows the type of interaction required with the structure fabricator and aircraft engineers,” says Chilcott. “First, you must understand the manufacturing process and, second, you must work with them to define the sensitivity required. This must be pretested to validate the level of damage they believe is required.” He adds that knowing there is a delamination is one thing, but engineers also typically want to know how big it is, “so they help set the thresholds for detection of crack initiation and propagation, and we design the system to meet those specifications.”

SMART Layer system design follows the same general approach, separating applications into local and global categories. Kumar describes, “Currently, we have two major platforms: Large-area SHM and SHM Patch. The latter is used for local monitoring of ‘hot spots,’ which typically span inches, while the test program we have with Airbus for the door surround areas on the A350 are Large-area SHM.” Images of the latter (see “Structural Health Monitoring: Moving from testing to NDT-integrated aerostructures” in “Editor’s Picks” at right) show a network of SMART Layers applied.

Kumar explains, “The way our SMART Layer is designed, you have a network of sensors but only one connection. If you are looking for small damage, then you need more sensors. For large damage, you need fewer sensors.”

She observes that in the longer term, that number of sensors might decrease because the data gathered would enable some refinement reduction in the number of sensors that are actually required. ”Once implemented across an operator [e.g., airline] or aircraft type, however, the sensor installation and inspection criteria would remain the same for all of the aircraft.”

Readouts and self-tests

Today, SHM systems are typically interrogated while the aircraft is at a terminal gate overnight. “We’ve developed a portable monitoring tool that you bring to the aircraft,” says Chilcott. “Each group of CVM sensors will be plumbed with very fine tubing to a test point socket that has a computer chip on it. You simply plug the portable monitoring unit into the socket, very similar to plug-and-play computer fittings, and the monitor will read the aircraft number, the site number being tested and will take a reference reading.”

In the case of CVM sensors, this reference reading is a baseline pump down profile from atmospheric pressure to vacuum. Chilcott continues: “Readings from this self-test are passed through software algorithms and clearly inform the operator if the vacuum ducting has been cut, if the sensor has disbonded, if there is a blockage within the sensor system or if everything is functioning normally. Then it takes a test reading.” If the pressure transducers detect airflow, it means either damage has occurred or the manifold that covers the etched grooves has been affected. (Chilcott says the latter is communicated clearly to the operator due to the larger volume of airflow.)

According to Airbus and other aircraft OEMs, self-diagnostic capability is a must for all SHM systems. “You have to have a system with the right steps in its operation process,” says Acellent’s Kumar. “We have these kinds of tools built into our systems to make sure they are OK and functioning properly. If we see that there is a bad sensor, we can eliminate that one and still obtain the monitoring. We design our sensor layouts with some redundancy to handle that type of issue as part of our fail-safe design.” She notes that software and the analysis algorithms built into it are key: “This is the meat of the whole system.”

Similar to the CVM systems, SMART Layers are also “on demand” systems. “When we plug our hardware in, it sends a signal to acquire data from the sensors,” Kumar explains. “When you excite the sensors, they become actuators and send a small stress wave through the structure. Any damage will interrupt this stress wave and show the damage as the wave is being read by the receiving sensors. The system analyzes the data and shows you that the damage is in this location, that it’s approximately this size, etc.”

“The readout is designed to be fairly foolproof,” says Chilcott. The CVM system records the self-test reading and then gives a very clear indication of what the thresholds are for this test site and what the signal is in comparison. “The results are basically pass or fail,” he adds, “and can be logged and plotted, showing a series of graphs over time. The whole operation typically takes less than five minutes.”

Cost and durability

“Our systems are pretty affordable,” says Kumar, “comparable to a handheld UT inspection system. But compared to using that equipment manually every time you suspect damage, ours is a one-time installation, so you are eliminating all of the scanning labor and time. You also don’t have to disassemble the aircraft to get to that part in question.” She notes that Acellent Technologies is working to bring the cost down as it pursues other large volume applications: “Larger volumes of sensors can bring the cost down a lot.” Kumar also points out that SHM systems for aircraft are designed to last 10-20 years. “Our sensors have been flying for five years already. If something should get damaged in service, it’s easy to replace parts of the system.”

Chilcott says the CVM sensors themselves are actually not that expensive. However, the system must be designed and tailored to each application through a close teamwork with the aircraft OEM and operator, and that does require some investment. But Chilcott contends its money well spent, noting that the Teflon pads and other parts in the CVM system don’t age. “We’ve spent a lot of time and money to make sure the materials will outlast the aircraft, and there are no moving parts to fail.” SMS has CVM systems fitted onto aircraft in 2003-2004 that are still flying (see “Decades of SHM demonstrations build confidence in local SHM” in “Editor’s Picks”).

Limitations and sensing options

CVM and SMART Layer systems can be used on metallic structures and any type of composite structure. According to Kumar, SMART Layer systems can monitor fatigue cracks, corrosion and perform load monitoring as well as incorporate other types of sensors (e.g., piezoelectric, fiber optics) into its networks. “We have already integrated temperature sensors, which feed back into our algorithms to make sure there is no signal problem caused by an increased temperature,” she explains, “We can also monitor for moisture, strain and acceleration, and still have only one sensor layer and only one connection. You don’t have to individually wire each of these monitoring functions, which greatly reduces cabling and labor. We’ve also demonstrated that our system can make sense of all this data.”

Although CVM systems cannot measure temperature or loads, they can monitor barely visible impact damage (BVID) using standard sensors installed on the back face of an impacted structure, and disbond using SMS’ Through the Thickness (TTT) sensors. SMS has demonstrated that CVM can reliably detect BVID by placing standard surface sensors, with detection galleries widely spaced, on the back face of an impacted structure. The impact on the structure causes micro-cracks in the resin matrix, which the CVM system can detect. Impacts as low as 5J, causing indentations as shallow as 0.1 mm, have been successfully detected on standard aerospace panel lay-ups.

For detecting disbond, TTT sensors require creating a small (<1 mm diameter) blind hole through the bonded structure and into the adhesive layer, which is then connected to an airflow meter and vacuum source. If the adhesive layer fails, the damage forms a leakage path for air that is then detected by the flow meter. The size of the detectable damage is determined by the spacing of the holes in the structure. TTT sensors have been used to detect poor manufacturing processes and damage due to impact on a complete composite structure, with results confirmed using standard c-scans and thermography.

Future systems

SMS is progressing system interrogation beyond just a handheld tool. “We are testing systems which have the interrogation capability also installed on the aircraft, so that the SHM data will be downloaded automatically along with all of the other data that is downloaded now when the aircraft is on the ground.”

Kumar notes that onboard interrogation systems are a little more complicated because there are a variety of options. “The hardware is onboard the aircraft,” explains Kumar, “but it may or may not be connected to the integrated vehicle health monitoring system, such as the health and usage monitoring (HUM) systems currently used on helicopters. Processing could be done in our hardware on the aircraft or in a ground station. Different aircraft platforms have different ways of accessing the information. So there is a range of options we are working on currently.”

Both companies agree that the future for all SHM systems is to be built into the composite structures.

Related Content

Innovation in ultrasonic inspection and nondestructive testing

With increasingly complex structural components working their way into aerospace programs, the need for versatility in inspection and testing capabilities is growing.

Read MoreRadalytica advances multimodal 3D robotic scanner for composites, future aircraft inspection

Radalytica continues to develop its RadalyX nondestructive testing (NDT) system, merging diverse imaging methodologies for inspection in laboratories to aircraft hangars.

Read MoreUTComp authors bulletin on fitness-for-service assessment of FRP

Welding Research Council (WRC) Bulletin 601 provides technical background and validation for quantitative nondestructive testing methodology for FRP composite equipment.

Read MoreXnovo Technology, Exciscope introduce X-ray tensor tomography technique

Through a strategic partnership, the companies introduce the FiberScanner3D module, dedicated to bringing more rapid, reliable and robust fiber structure characterization methods to lab settings.

Read MoreRead Next

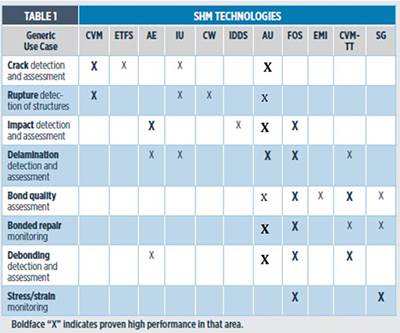

Structural health monitoring: The toolbox

There are a broad range of SHM technologies that take advantage of a variety of sensing mechanisms. Here's a short sketch of each, accompanied by tables that indicate current uses and developmental progress.

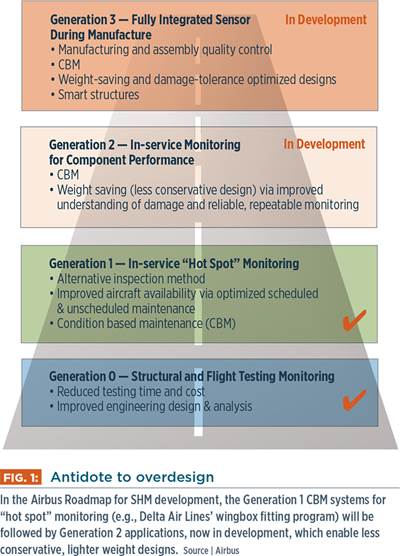

Read MoreStructural health monitoring: NDT-integrated aerostructures

SHM moves from structural testing to an FAA-qualified inspection alternative, to reduce cost, streamline operations and mature toward lighter, more robust smart structures

Read MoreStructural health monitoring: Decades of demos build confidence

Current momentum in local structural health monitoring development can be credited to a great deal of developmental effort on the part of these system developers.

Read More

.jpg;maxWidth=300;quality=90)