Structural health monitoring: The toolbox

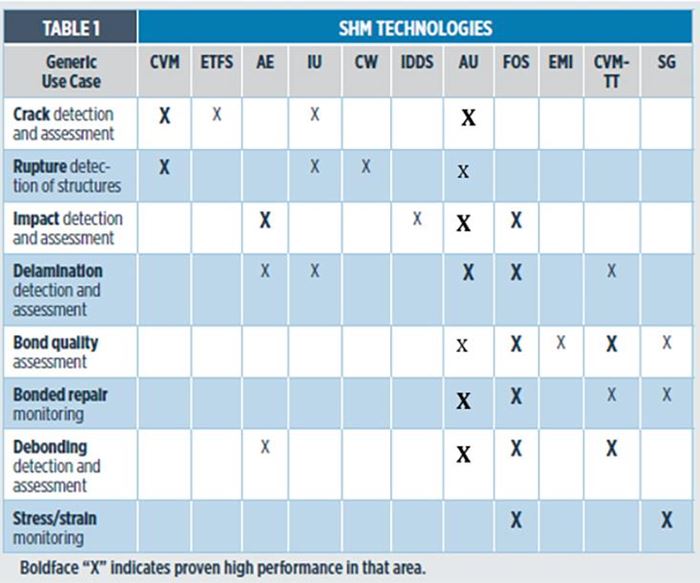

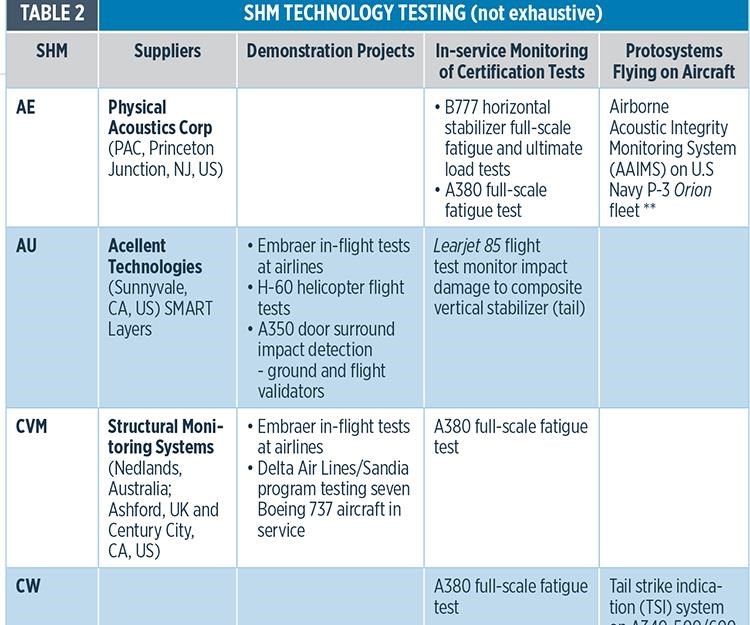

There are a broad range of SHM technologies that take advantage of a variety of sensing mechanisms. Here's a short sketch of each, accompanied by tables that indicate current uses and developmental progress.

Although CW’s coverage of structural health monitoring (SHM) technologies in this issue focuses on those most actively employed in testing/demonstration environments and most ready for widespread deployment, there are a broad range of SHM types that take advantage of a variety of sensing mechanisms. The following is a short sketch of each, accompanied by two tables that indicate current uses and developmental progress.

Acoustic Emission (AE): Passive transducers listen for matrix cracking, delamination and fiber breakage.

Acousto-ultrasonics (AU): A grid of piezoelectric sensors sends and receives ultrasonic pulses and analyzes changes in wave patterns to identify and describe damage.

Comparative Vacuum Monitoring (CVM): The smallest air flow can be detected when galleries alternating between atmospheric pressure and vacuum (enabled by Teflon manifold patch) are breached by a crack or resin microcracks.

CVM Through the Thickness (CVM-TT): A <1 mm-diameter hole drilled through a composite into adhesive uses the CVM principle to detect disbond and delamination.

Crack Wire (CW): Conductive/resistance wires that trigger alarms when severed by cracks or damage.

Electro-Magnetic Interference (EMI): Uses embedded piezoelectric sensors and impedance analyzer. Increasing levels of internal release agent and moisture contamination, for example, produce increasing deviation from a reference index, indicating weak bonds.

Eddy Current Foil Testing Sensors (ETFS): Sensors generate an eddy-current field in conductive metals, which is disrupted by cracks and corrosion.

Fiber Bragg Grating (FBG): A mature type of Fiber Optic Sensing (FOS), it uses alterations in the refractive index of an optical fiber to measure temperature, strain and vibration as well as acoustic and ultrasonic signals for crack and damage monitoring.

Impact Damage Detection System (IDDS): Developed by Kawasaki Heavy Industries, this system uses two combined methods: (1) optical intensity measurement before and after impact, using optical fibers to assess damage and (2) shock wave measurement for impact localization via FBG sensors.

Imaging Ultrasonics (IU) — Miniaturized, integrated sensor networks generate a signal through the material. Changes in wave reflection indicate flaws or damage.

Strain Gauges (SG) — These output strain, stress and load, using traditional electrical foil sensors and an input voltage. Newer sensor types include fiber-optics, microelectromechanical systems (MEMS) and printed conductive-ink sensors.

This short article is a sidebar to a feature story titled "Structural health monitoring: NDT-integrated aerostructures enter service," for which there is also a companion sidebar, titled "Structural health monitoring: Decades of demonstrations build confidence in local SHM." To read either story, click on its title under "Editor's Picks," at top right.

Related Content

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

-

Gatorbar, NEG, ExxonMobil join forces for composite rebar

ExxonMobil’s Materia Proxima polyolefin thermoset resin systems and glass fiber from NEG-US is used to produce GatorBar, an industry-leading, glass fiber-reinforced composite rebar (GFRP).

-

SGL Carbon carbon fiber enables German road bridge milestone

A 64-meter road bridge installed with carbon fiber reinforcement is said to feature a first in modern European bridge construction, in addition to reducing construction costs and CO2 emissions.