Flexural test method standards for composite materials

Dr. Donald F. Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) proposes a common-sense standard method for flexural testing of composite materials.

My March column addressed flexural test methods for composite materials. I noted that the details presented in the various available national and international standards were not mutually consistent (see “Flexural testing of composite materials" under "Editor's Picks," at top right), but most of these inconsistencies were of little consequence because variations in these parameters have little effect on test results. But I also pointed out a problem: a testing group is typically required by its customer to follow a specific standard. Because there are a number of different standards, the testing lab must continually alter its procedures and, possibly, its test equipment, to conform with each customer’s specified standard, despite the fact that these alterations have little to no influence on the results. I concluded that testing specialists would be well served by a single international standard.

Table 1 presents a representative list of industry standards for flexural testing of composite materials. It includes the three current ASTM standards and the relatively new ISO Standard 14125, which was specifically written for composites (released in 1998, amended in 2011). ISO 178, written for plastics and short-fiber composites (≤7.5 mm/0.30 inch), is an older standard that is now in its fourth edition (2002) as amended in 2004. The CRAG Method 200 (from the Composites Research Advisory Group, U.K.) and the British Standards Institution (BSI) Standard 2782, Method 1005, are examples of European standards. BSI 2782 is identical to European Norm EN 63:1977 (Comité Européen de Normalisation (CEN, Brussels, Belgium).

ASTM D 790 was the first ASTM standard for flexural testing, published in 1970 by its D20-Plastics Committee. It originally included three- and four-point loading and was well known within the composites community. In the late 1990s, it was revised to eliminate four-point loading.

In response to complaints from the composite materials community, D20 issued ASTM D 6272, essentially a copy of D 790 (as indicated in Table 1), including only four-point loading, with either quarter-point or third-point load location. ASTM’s D30-Composites Committee then began working on its own flexural testing standard, published as ASTM D 7264 in 2006. It includes three- and four-point loading, but only quarter-point load location for four-point loading. The two D20 standards contain much more detail than D 7264, some of which is footnoted in Table 1, because they cover a variety of plastic forms and composites.

Today ISO 14125 is the leading non-ASTM standard. Like ASTM D 7264, it is focused specifically on composite materials and presents relatively concise guidelines and test conditions. Unfortunately, the ISO 14125 specifications are somewhat different than those published in ASTM D 7264.

Table 1 also shows that both three- and four-point loading remain popular. Which is better? There is no industry consensus. However, four-point loading induces a constant maximum bending stress over the whole section of the beam between the loading points. In three-point loading, the maximum bending stress occurs only at the cross section where the load is applied. Thus, although it is sometimes argued that three-point loading is easier to apply, the nod will be given to four-point loading.

It is interesting that ISO 14125 specifies a third-point load location for the four-point loading configuration, and ASTM D 7264 specifies a quarter-point load location, but the original ASTM D 790 standard permitted both, and so, subsequently, did ASTM D 6272. It appears that the position of the loading points on the beam has little influence and, therefore, should be arbitrarily standardized. In acknowledgment of the fact that the applied forces required to achieve a given bending moment in the beam are one-fourth less if third-point load location is used, I suggest third-point load location as the universal standard when four-point loading is used.

In Table 1, some standards specify a specific specimen length, while others specify only a support-span-length to specimen-thickness ratio, ℓ/t. The ℓ/t is important to test performance in terms of controlling the induced shear stresses. And specimen thickness (t) is dependent on the form of the material available for testing. It follows that specimen length is not a governing parameter. It is interesting, then, that both ASTM D 7264 and ISO 14125 specify a specimen length, which dictates a specimen thickness for a given ℓ/t ratio. I suggest that the ℓ/t ratio be specified and the specimen length be dictated by whatever material thickness is to be tested. An ℓ/t ratio of 16 is usually adequate. Thus, standardizing an ℓ/t ratio of 32 will provide a margin of safety.

The existing standards do not vary much with respect to recommended specimen width. Adopting a standard 15-mm width would be reasonable.

The radii of the loading points and supports has limited influence on test results, as long as the radii are not so small that they concentrate the applied forces onto a very small area of the beam, inducing local contact stress failures. Conversely, larger radii distribute the applied forces over larger areas and thus are beneficial. This fact is typically recognized in three-point loading, for example, where the loading point radius is sometimes made larger than the support radii because the loading point force is twice as high as the support point forces. But more commonly, as seen in Table 1, all radii are the same but (presumably) large enough to avoid local contact stress failures.

There is a trend within the composites community to make the loading and support radii even larger than those specified in Table 1. For example, radii of 10 mm/0.4 inch or more are sometimes used, twice the size of the typical 5-mm/0.2-inch radii. But because 5 mm appears to be adequate when testing most composite materials, this would be a reasonable standard.

Thus, we have defined a standard test method:

Loading Method 4-point @ 3rd points

Specimen ℓ/t Ratio 32

Specimen Width 15 mm

Support/Loading Radii 5 mm

Little else need be specified.

Related Content

Photothermal tomography for locating, quantifying defects in composites

Years of infrared testing development result in thermography technology that is no longer just qualitative, but can define defect size and depth, making additional UT scans obsolete.

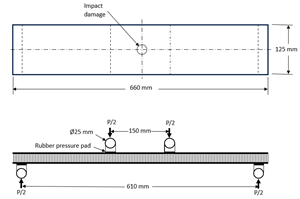

Read MoreDamage tolerance testing of sandwich composites: The sandwich flexure-after-impact (FAI) test

A second new ASTM-standardized test method assesses the damage tolerance of sandwich composites under flexural loading.

Read MoreTesting to support composite bolted joint analysis

An overview of ASTM Standard Guide D8509, and its coupon-level mechanical testing of design properties for analyzing composite bolted joints.

Read MoreInterlaminar tensile testing of composites: An update

New test method developments for measuring interlaminar tensile strength address difficulties associated with the ASTM D6415 curved beam flexure and ASTM D7291 flatwise tensile tests.

Read MoreRead Next

Flexural testing of composite materials

Dr. Donald F. Adams (Wyoming Test Fixtures (Salt Lake City, Utah) takes look at flexural testing and promises recommendations, next time, for a unified standard.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More