From the CW Archives: The life and death of the BMW i3

A look back at the ambitious and impressive composites production system BMW developed for production of the all-electric i3 EV.

Scott Stephenson (left) and Jeff Sloan in 2014 in front of a BMW i3 at the company’s Leipzig, Germany, production facility. Source | CW

One of the most memorable plant tours I went on was of the BMW i3 production line in Leipzig, Germany. I visited in March 2014 after JEC with Scott Stephenson, CW’s events and strategy chief.

In case you’ve forgotten or never knew, the BMW i3 was an electric vehicle (EV) the company developed in the mid-2000s. It had a range of 100 miles, seated four people and was designed for the urban/suburban environment.

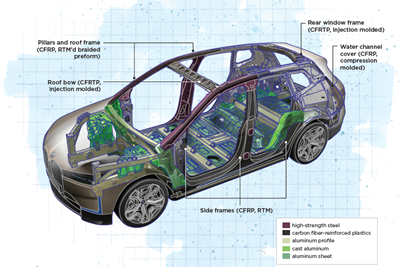

But what drew me and Scott to the plant was the fact that the i3 was manufactured — very ambitiously — almost entirely from carbon fiber composites. Most notably, it featured a body-in-white (BIW) — called a Life Module — comprised of a resin transfer molded (RTM) frame that was adhesively bonded together via a highly roboticized automation system.

This was not trivial and represented a bold application of composites in a production vehicle at a scale that had never been attempted before. Further, BMW accomplished the feat by doing something very unusual: It acquired the entire supply chain of composite materials and structures for the i3 — including polyacrylonitrile (PAN) precursor (Japan), carbon fiber manufacturing (U.S.), as well as carbon fiber weaving, RTM and component subassembly (Germany, Germany and Germany).

This is not to say that composites don’t have a place in automotive manufacturing — but it may be an evolution, not a revolution.

BMW’s strategy appeared to show the automotive industry a way forward for the application of composites in primary structures and was regarded as a revolutionary shift in automotive composites manufacturing. Scott and I visited the Leipzig plant at the zenith of this apparent revolution.

The story that resulted, published in June 2014, is here: “BMW Leipzig: The epicenter of i3 production.” I clearly remember a few things about this visit. First, BMW operates incredibly clean and efficient manufacturing spaces. Everything was in its place and there was a place for everything. Second, BMW spared no expense in equipment, tooling, machinery or automation to make i3 production as efficient as possible. Third, Rene Koschkar, the engineer tasked with managing composites fabrication for the i3, struck me as incredibly knowledgeable, incredibly able, incredibly busy and incredibly young. He bore ultimate responsibility for making sure the facility’s complex composites fabrication and bonding operation operated smoothly enough to meet the 100 vehicles/day production rate. It was a daunting and ambitious job.

BMW produced the last i3 in July 2022, ending the car’s 9 years on the market. In the process, BMW dismantled the carbon fiber supply chain it had built for the vehicle, effectively ending what proved to be a grand experiment in automotive composites manufacturing.

It also ended the hope BMW created that a paradigm shift in automotive manufacturing was underway. This is not to say that composites don’t have a place in automotive manufacturing — but it may be an evolution, not a revolution. Indeed, BMW continues to apply carbon fiber composites to its vehicles, but not as ambitiously as it did for the i3.

In the meantime, a pre-owned i3, if you’re in the market, will set you back at least $20,000 today, a testament perhaps to its unique architecture and aesthetic. There is even an argument for the i3 being a cult classic. In any case, the vehicle remains a testament to what composites can do in a relatively high-volume automotive manufacturing environment.

Related Content

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreRead Next

BMW rolls out multi-material Carbon Cage with 2022 iX vehicle line

For its new battery-electric iX sports activity vehicle, BMW combines CFRP strategies from previous i3, i8 and 7-Series designs and adds CFRTP for a lightweight, rigid frame.

Read MoreFrom the CW Archives: I see thermoplastics in your future

Thermoplastics are evolving quickly into larger structures and clearly will have a significant role to play in the next commercial aircraft program — whenever that’s announced. This edition of “From the CW Archives” looks back on a thermoplastics pioneer.

Read MoreFrom the CW Archives: Fast-cure epoxies for automotive fabrication

Sara Black’s 2015 report on the development of snap-cure epoxies for automotive manufacturing still resonates today.

Read More