As carbon fiber-reinforced polymer (CFRP) and ceramic matrix composite (CMC) materials proliferate in aircraft engines, space components and hypersonic applications, machining becomes an issue where precision and efficiency can alter program outcomes. Trying to machine high-reliability and high-accuracy features into CFRPs and CMCs can be challenging due to their hardness and abrasiveness, resulting in slow machining rates, undesirable effects on material properties, inability to meet parts specifications and high operational costs, including recurring tool replacement.

To meet this challenge, a range of laser technologies have been developed for machining such advanced composites. While lasers offer the potential for increased efficiency and elimination of recurring tool costs, the heat generated dissipates into the material, creating potential for microcracking and material change. Lasers also cut at the focal point of the light beam, resulting in V-shaped cuts that can be problematic for precise tolerances.

Laser MicroJet technology developed by Synova (Duillier, Switzerland) creates a laser beam that is entirely contained within a waterjet. The laser is reflected at the air-water interface, similar in principle to an optical fiber, while the water cools the cutting zone and washes debris from the kerf. Advantages of the Laser MicroJet compared to conventional lasers reportedly include no burning or thermal degradation, fewer burrs for smoother surfaces, straight-sided cuts and higher precision.

CW first encountered the Laser MicroJet in its 2017 tour of GE Aviation’s Asheville, N.C., U.S. production plant for CMC engine components. Here, it is used to machine holes in CMC shrouds for LEAP aircraft engines. “This technology helps to maintain a high level of accuracy in the hole diameter,” says Ryan Huth, GE Aviation’s manager for CMC production. “The MicroJet can drill these holes in two minutes versus one hour with conventional machining,” says Huth. CW’s sister magazine, Modern Machine Shop, has also published an informative article on the Laser MicroJet.

The power of water and light

Synova was founded in 1997 by Dr. Bernold Richerzhagen, who patented Laser MicroJet technology after his research at the Federal Institute of Technology (EPFL, Lausanne, Switzerland) in the 1990s. The technology was broadly adopted for semiconductor wafer dicing in 2001. Synova then established local subsidiaries in the U.S., Japan, India and Korea in 2003. These have been expanded to now include micromachining centers, with near-term expansion planned for Taiwan and China. In 2009, Synova established a cooperative development partnership with Makino Milling Machine Co. Ltd. (Tokyo, Japan), introducing a new machine series and advancing these for the machining of medical devices, watch mechanisms, gas and jet engine turbine blades, semiconductor devices and cutting tools from superhard materials.

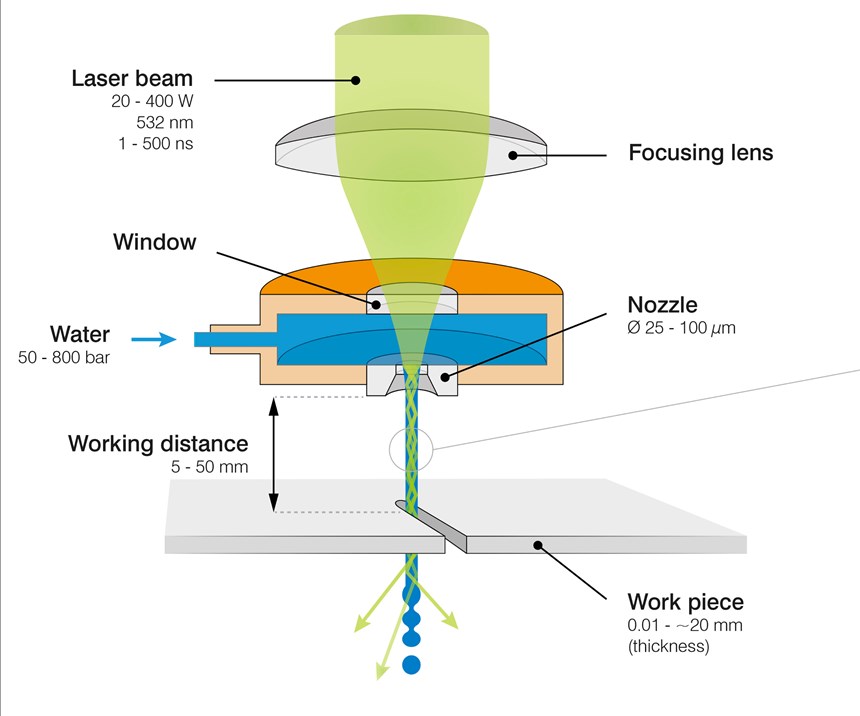

In the Laser MicroJet system, a laser beam passes through a pressurized water chamber and is focused into a nozzle. The lasers are a common industrial type — solid state Nd:YAG — with a power of 10-200 watts and a wavelength of 1,064 (infrared), 532 or 355 nanometers. The hair-thin jet — diameter of 50-70 microns — of filtered, deionized water is used at a low pressure of 200-650 bar. This results in low water consumption, on the order of 2-3 L/hr, and a negligible force of less than 0.1 newton exerted on the material.

How is it possible to achieve efficient laser ablation within water? “The laser is pulsed roughly 10,000 times per second,” explains Jacques Coderre, Synova business manager for the U.S. “For each laser pulse, a plasma is generated that pushes the water upwards, enabling ablation to occur. At the end of the pulse, the plasma collapses and the water now cleans the surface and dissipates the heat.” He notes the waterjet also eliminates the complexity and process variations of maintaining the laser in focus typically required with dry laser systems. “This enables cutting thick or non-flat parts without having to worry about being in focus,” says Coderre. “The technology also produces a cylindrical laser that creates perfectly parallel walls with tight kerf widths.”

Configuring for composites

The Laser MicroJet performs well not only for CMCs, but also for CFRP and stacked laminates. During testing, it produced 3-millimeter-diameter holes in a 2.6-millimeter-thick carbon fiber-reinforced plastic (CFRP) laminate at speeds up to 1,440 mm/min. “With a conventional laser, you have to slow down because of heat,” notes Coderre. “Conventional mills can achieve similar speeds but have higher operating costs due to required tool replacement.”

The Laser MicroJet can cut 1-inch-thick CMC laminates. “The speed is based on a pretty constant ablation rate of 1 mm3/min,” Coderre observes.

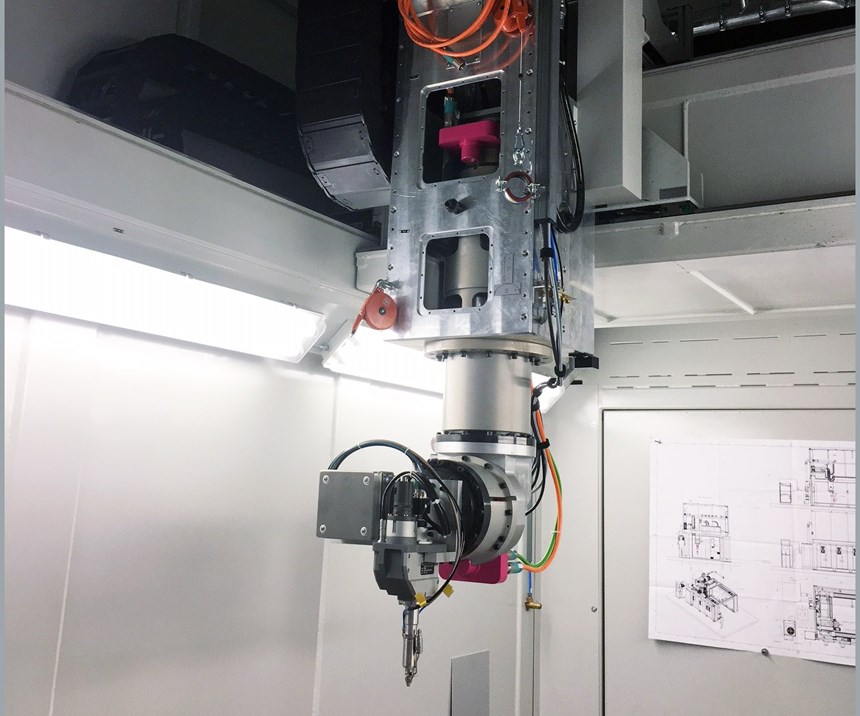

Synova has a range of machines, introducing its five-axis CNC LCS 305 system last year. “This machine excels at high-accuracy 3D cuts and is well-suited for small, CMC parts,” Coderre explains. “But it is not a good fit for large CFRP parts.” For this, Synova has integrated its Laser MicroJet into a gantry machine, capable of machining parts larger than 2 meters by 3 meters. “It is also easy to integrate with robots and easy to program,” he adds. For 2D cuts, the MicroJet software converts a CAD file into machine code. Once verified, the operator simply presses a button and the machine performs the cutting routine. For 3D cuts, Coderre explains that a postprocessor extracts the necessary 3D data from the CAD file and formats it for the Laser MicroJet.

For Factory 4.0 capability, a laser power meter, positioning sensor and automatic jet angle correction are integrated into the Laser MicroJet system. “It is very flexible,” says Coderre, “easy to incorporate into parts production as a standalone system or as part of fully automated lines for operator-free, high-volume production.” The technology has already been proven in CMC parts for the LEAP aircraft engines, he continues. “For composites, it offers lower manufacturing costs, achieved through faster production speeds, reduced operational costs, higher reliability and higher yields.” Such efficiency is indeed what composites need as new materials, markets and competitive metals technologies continue to evolve.

Related Content

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreFrom the CW Archives: Fast-cure epoxies for automotive fabrication

Sara Black’s 2015 report on the development of snap-cure epoxies for automotive manufacturing still resonates today.

Read MoreTCR Composites introduces TR1116 snap-cure epoxy prepreg resin system

Designed for press-cure applications, the resin system is highlighted for its snap-cure capability and tailored properties.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)