High-precision carbon fiber pultrusions for CERN

Tight-tolerance composite structures enable one of the world’s leading laboratories for particle physics.

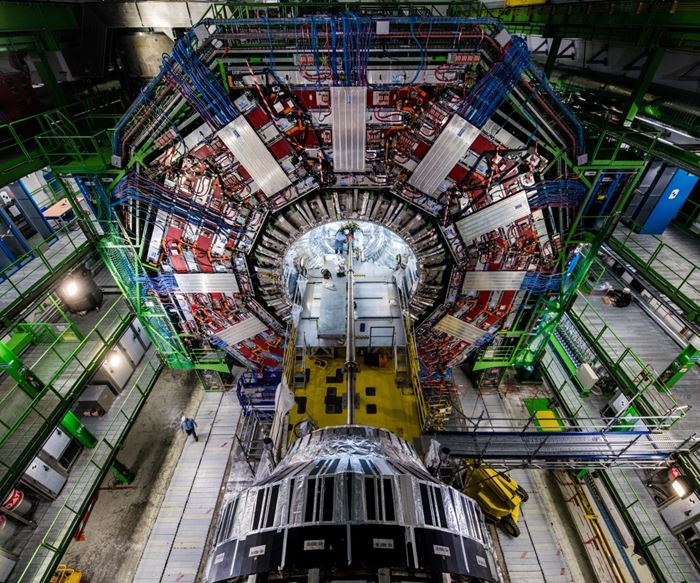

CERN, the European Organization for Nuclear Research, is one of the world’s leading laboratories for particle physics. Its Large Hadron Collider (LHC, Geneva, Switzerland) is the world’s largest and most powerful particle accelerator and reportedly qualifies as the largest single machine in the world. It consists of a 27-km ring, within an underground tunnel, fitted with superconducting magnets along with accelerating structures to boost the energy of the sub-atomic particles. Inside the LHC, two high-energy proton beams travel at close to the speed of light, in opposite directions, before they are made to collide at four locations around its ring. LHC’s Compact Muon Solenoid (CMS) detector sits at one of the four collision points and records the paths taken by particles using a silicon tracker consisting of around 75 million individual electronic sensor channels arranged in 12 concentric layers. The tracker needs to record particle paths with very high precision, yet be lightweight, to disturb the particles as little as possible.

Exel Composites (Mäntyharju, Finland) had collaborated with CERN in the past, supplying approximately 200 km of electrically insulating fiberglass composite profiles for the LHC’s electrical system. CERN turned to Exel again, to supply elements of the 688 high-precision structures that support the silicon tracker modules within the CMS detector. Very thin yet accurate carbon fiber profiles were needed, and Exel had a proven track record for producing pultrusions to tight tolerances.

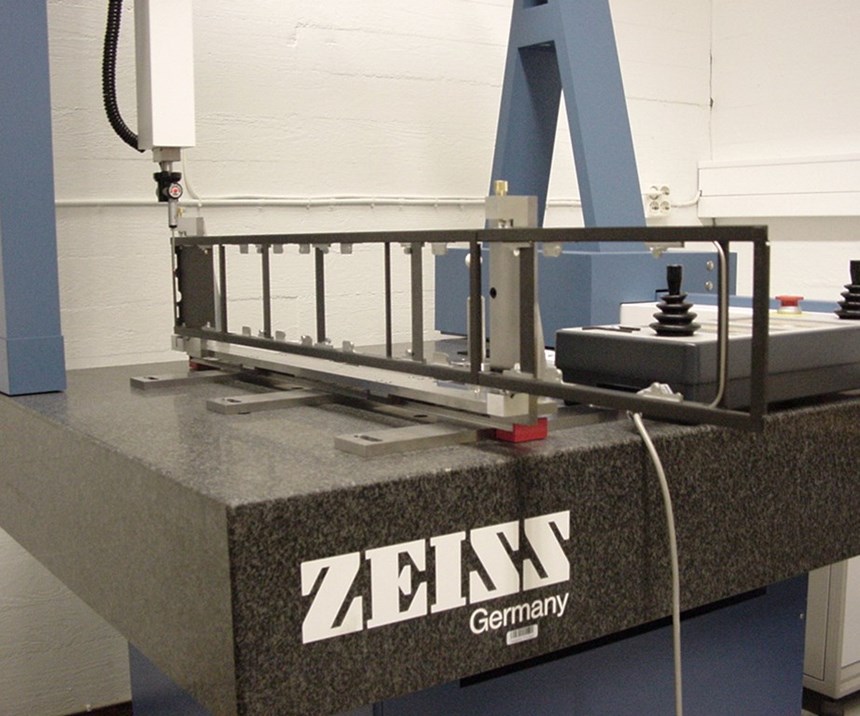

Each of the 688 structures was made up of two, 1.2m-long pultruded carbon fiber/epoxy composite U-profiles of 0.7-mm wall thickness, together with L-shaped crossbars, to form a frame structure on which the particle-detecting modules would sit. To achieve the high levels of stiffness and thermal stability required, Exel designed the profiles using high-modulus unidirectional (UD) carbon fiber. A thin glass fiber surface veil was also employed to facilitate processing. All of the components and fixtures were then assembled and bonded on jigs at the Helsinki Institute of Physics to create structures with a dimensional tolerance of ±0.05 mm. The pultruded frames delivered light weight and radiation transparency, and met the extremely tight dimensional tolerances, straightness requirement and necessary mechanical properties at the low temperatures maintained in the CMS.

Exel delivered the tracker support profiles to CERN from 2001 to 2005, with the final operational use starting in 2008. The CMS detector has been performing well, culminating in 2012 with the discovery of a new elementary particle, the Higgs boson. Says Antti Onnela, CMS Tracker Project Engineer at CERN, “We had quite challenging requirements for these composite structures and earlier laminated versions did not meet them. Exel developed the needed thin-walled U-profiles that turned out to be technically superior, but also more economical thanks to the production process that minimized the wastage of expensive carbon fiber. After nine years in service in the CMS the Exel parts continue performing as flawlessly as in the beginning.”

Related Content

-

PulFlex introduces pultruded Flex Connect

Fiberglass T-slot, primarily used for automation, framing and other quick setup systems, competes with aluminum alternatives.

-

Pultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

-

Pultrusion, pull-winding showcase high-volume composites production

JEC World 2024: Exel Composites offers attendees a chance to engage with company experts and learn more about continuous composite manufacturing processes across various industries.