Hybrid resin system: Epoxy benefits, without the epoxy

Rapid cure, zero tack material ideal for automated, higher-volume production.

A couple of years ago, Solvay Composite Materials (Alpharetta, Ga., U.S.) introduced a new carbon fiber-reinforced prepreg, SolvaLite 730, specifically developed for higher-volume automotive production. The product is said to offer shorter cycle times, less scrap during shutdown, zero tack for better automated handling, and lower labor, thereby reducing manufacturing costs — a desirable combination for automakers and suppliers, especially as carbon fiber composites expand into higher-volume vehicle platforms. Solvay was vague at the time of its introduction about what this material actually was, but more details have emerged; what we now know about SolvaLite 730 follows.

First, the matrix resin is not epoxy. Rather, it is based on a “toughened, highly engineered” vinyl hybrid resin system. It is designed to be styrene-free and very low in volatile organic compounds (VOCs) — something easy to do with epoxies but a real challenge with traditional unsaturated chemistries such as vinyl esters and unsaturated polyesters. Follow-on benefits are that this prepreg does not require freezer storage and temperature-controlled transportation (currently costly and rate-limiting steps), but rather can be kept at room temperature. "We see the primary benefit of not requiring frozen storage to be that it hugely simplifies inventory control," explains Dr. Stephen Jones, Solvay's materials scientist-composite materials, who worked on formulation of the final products. "Material can be stored, and plies, kits and preforms can be produced and managed, without the need for freezing and defrosting, which take space, time and cost money (both capital and operating expenses). Also, they add risks to production that are absent with metals." Another benefit is that at shift’s end, unused material need not be discarded, but rather can be covered and returned to a shelf for use at a later stage. The material has a long outlife (minimum 6 months), yet snap cures in less than 60 seconds at 170°C, making it fast enough to supply 150,000 parts/year from a single toolset. (In thin cross-sections, the material is said to cure in 45 seconds at 170°).

Another benefit of the hybrid resin system vs. epoxies is that processors need not choose between using a solid hardener (curative) that diffuses well through lightweight, high-cost fabrics, but poorly through less costly heavy fabrics, or a liquid hardener that works with either reinforcement but leads to short outlife.

“Another benefit of the novel unsaturated chemistry we developed for SolvaLite 730 is that it has lower enthalpy than epoxies and uses liquid organic-peroxide curatives that are slower and more stable than epoxy curatives at lower temperatures and faster at higher temperatures,” adds Jones. “Low enthalpy means there is little risk of uncontrolled exotherm [excessive heat generation followed by degradation of the polymer] even when curing in 3 minutes or less.”

Three grades with different carbon fiber reinforcement are currently offered: 300-gsm/50K unidirectional; 190-gsm/50K unidirectional; and 380-gsm/12K twill-weave. “We decided to keep it simple when we first introduced this material,” notes Glade Gunther, Solvay’s North American program manager-serial automotive. “We figured we could always add more options if the product was well received.” He adds that the product was not designed for typical bonded body panels but rather for more demanding chassis and vehicle-structure elements. The material is said to wet out tools very well and leave “no weird pits and bumps” but also releases well. While it is autoclavable, it also is compatible with out-of-autoclave systems where it is typically formed at 100-300 psi/7-21 bar. “You don’t need to crush it,” Gunther adds.

The current formulation is the result of three years’ effort to help improve supplier margins and produce a prepreg that is better suited for medium-volume automotive production. “A lot of work went into ensuring the material could be handled with automated equipment and that it is not too stiff, not too soft, not crispy and definitely not sticky,” adds Jones. “We worked hard to tailor the rheology to make sure we had zero tack, but kept good wetting at cure temperatures.” This attention to tack is a benefit for processors working on higher volume automotive programs because the material leaves no sticky residue on robots and pick-and-place equipment, making it practical to automate blank production and layups, including designs with non-constant thickness. To achieve 1-minute or faster cures, blank warmup time is said to be critical and tends to be part- and tool-dependent. Also, rapid tool closure is vital and that is difficult to achieve without automation. No surprise that inconsistency in things like hot/cold spots, timing and average temperature also hurt fast-production goals.

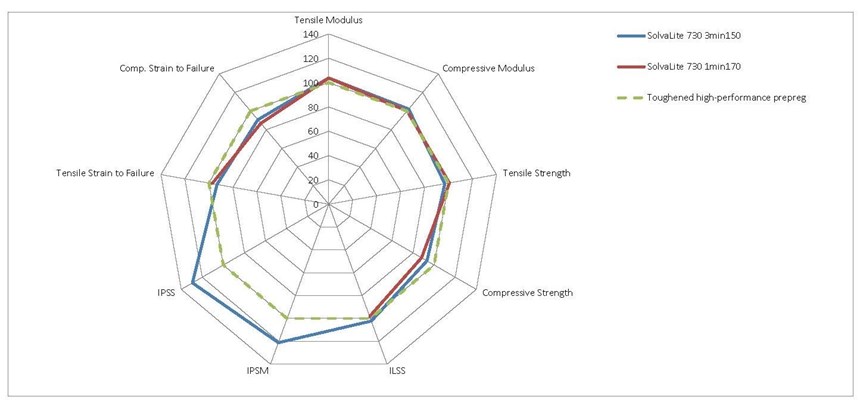

Mechanical properties of SolvaLite 730 are said to be comparable to or better than standard autoclave-cure prepreg (with the same reinforcement types) that is already used in automotive. So far there is no paint data on the prepreg, but it is said to offer good UV stability. Reportedly, the material is currently being trialed on a variety of structural applications (including A, B, and C pillars and transmission tunnels) across a number of developmental vehicles.

Related Content

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

Solvay launches FusePly aerospace composite bonding technology

FusePly enables the build of bonded composite parts using conventional manufacturing processes, through the creation of covalently bonded structures.

Read MoreSolvay launches release film for wind industry, displays thermoplastic auto component

At JEC World 2019, Solvay jointly displayed a thermoplastic composite steering knuckle and launched VAC-PERF A2400, a next-generation release film for the wind industry.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)