To ensure that the speed of composites fabrication keeps pace with customer demand, the ability to inspect and monitor composite part quality must become an integral part of high-rate part manufacturing. CW follows up its coverage of automated, in-process inspection and verification, begun in February (see “Improving composites processing with automated inspection”), with news about three providers and their approaches to addressing the growing need for inline inspection.

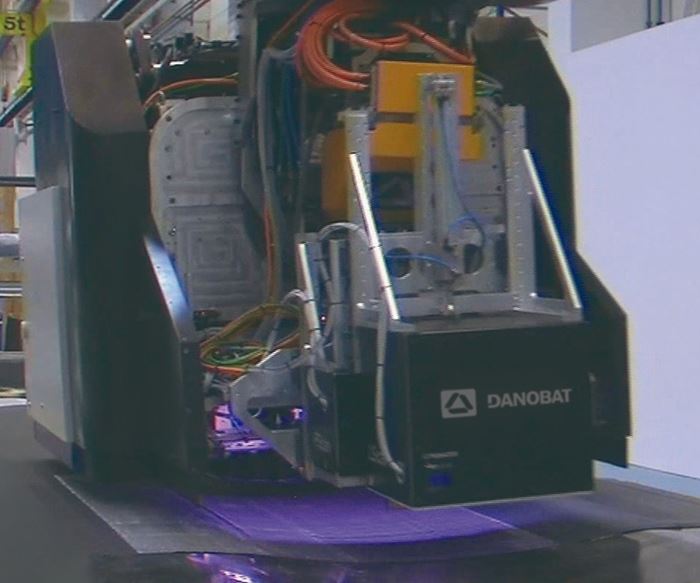

One is Danobat Composites (Elgoibar, Spain), a cooperative company owned by Mondragon Corp. (Mondragon, Spain). A specialist in automated manufacturing solutions, including those for composites fabrication, its high-speed Automated Dry Material Placement (ADMP) technology is well-known in the wind industry as well as aerospace (see Learn More) for its ability to rapidly lay down wide multiaxial and broadgoods preforms for infusion. Danobat is developing technology and software systems to support automated process inspection for its ADMP machines.

The second group is Fives Cincinnati (Hebron, KY, US), a provider of familiar automated composites manufacturing equipment: Viper automated fiber placement (AFP) machines, Gemini dual AFP/automated tape laying (ATL) machines, Charger ATL machines and, through its Forest-Liné division (Granby, QC, Canada), ATLAS tape layers. Together with Fives Lund (formerly Lund Engineering, Seattle, WA, US), a custom manufacturing design firm, Fives Cincinnati has developed a real-time, in-process inspection system for AFP/ATL that, it claims, puts a new and improved twist on inline inspection methods now in commercial use.

The third is Apodius (Aachen, Germany). This subsidiary of Hexagon Manufacturing Intelligence (Cobham, Surrey, UK) has developed successive iterations of its Apodius Vision System, an automated quality control system for low- and high-rate composites production, including automotive parts, that is still economical for smaller facilities.

Dry control, rapid defect detection

“With dry fabric, placement defects and any defects that stem from the fabric’s structure must be rapidly detected,” says Asier Gandarias, business development manager of Danobat’s composites division. “We are currently focusing our efforts on two types of inspection systems for our ADMP technology.” The first uses a laser profilometer, or LLT (laser line triangulation) sensor, to map the edges of the dry materials during lay down and detect whether fabric positions are within the specified tolerances. The company has developed algorithms in-house for measuring and comparing the edges to specifications. Gandarias notes that the system is being developed to function in two ways: 1) lay a first course of fabric and measure the edges in a second pass; and 2) carry out the inspection as the material is placed in real time. Challenges of LLT include process speed and ensuring that data collection and processing keep up with the machine; perfecting the filtering algorithms based on complex mathematics; and being able to inspect any fabric type, without loss of performance.

The second method involves a combination of LLT sensing and photometric scans with camera sensors. This work is an outgrowth of the European ZAero Project, which CW has reported on (see “Zero-defect manufacturing of composite parts”), involving Airbus and several machine equipment suppliers, with the goal of “zero-defect manufacturing.” Danobat has worked extensively with machine vision specialist Profactor (Steyr, Austria) to develop a robust automated inspection system with integrated sensors within the ZAero project. The system goals are more ambitious: Beyond what the first method does, it detects fiber distortions, foreign objects and missing stitches in the dry multiaxial fabrics laid down during part manufacturing, using the two types of sensors.

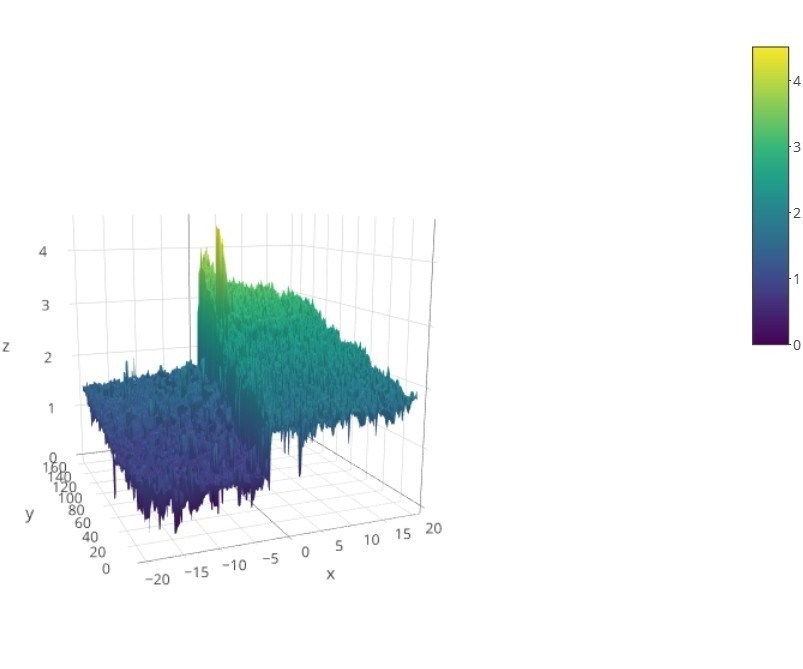

“For inspection of dry material placement, a special variant of a laser triangulation sensor is used,” explains Gandarias. “The idea is to extract the 3D shape of the surface right after placement of the ply. Because we work with very wide widths of fabric, the sensor’s field of view has to be large, but at the same time, produce high-resolution images,” he points out. The sensor system, thus, includes multiple lasers and cameras to enable the calculation of the height profiles. To ensure accuracy, Danobat uses a high-precision calibration method that ensures correct orientation of the sensors with respect to the ADMP machine’s coordinate system.

In terms of software, Danobat has developed its Advanced Relationship Model (ADRM) to process the collected inspection data. For the first method (with a single LLT sensor), the collected points are saved and displayed in the human machine interface (HMI) screen display. In the second method, with multiple sensors, an image of the entire ply is shown with all required information. Gandarias notes that the system is employed in wind blade manufacturing, where the LLT sensor detects wrinkles during laydown and the multi-camera system detects gaps or overlaps between plies, enabling real-time corrections of material placement. Now, with the ZAero project, Danobat is focused on the aerospace sector, and is manufacturing test samples and parts for OEMs as part of private collaborations and publicly funded research projects.

Automated inspection for contoured AFP

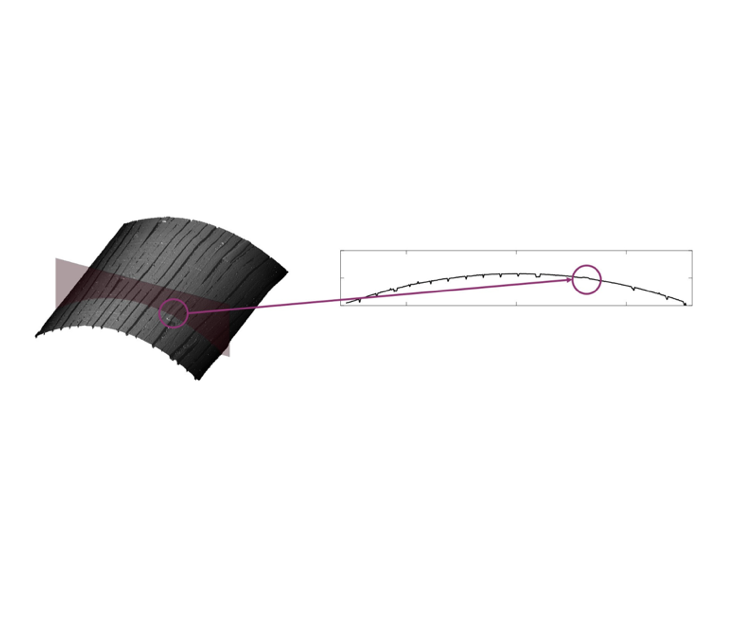

“We have a lot of experience with LLT sensors inspecting medium-contour applications and have been evaluating commercial offerings and designing our own LLT sensors for more than 5 years now,” says Erik Lund, CEO and chief technology officer at Fives Lund. “We’ve taken a large amount of data and made hundreds of large parts, utilizing an automated, in-process inspection system with LLT sensors.”

The outcome of the company’s experience and research is a new industrial sensor, targeted to inspection of highly contoured components. The sensor, says Lund, enables highly accurate measurements when mounted on a machine head in a position that does not impede the machine path.

Gil Lund, senior project engineer at Fives Lund, explains that his team has performed extensive testing and benchmarking of inspection solutions for several years, which has helped prioritize development of its inspection solution: “Surface profilometry describes many different techniques for noncontact measurement of surfaces, including surface finish — gloss, texture — and shape (for example, flatness, curvature, waviness), of which laser line triangulation is but one subset.” Because the physics of LLTs requires a triangle-shaped sensing configuration, he says, it can make taking measurements tough during fiber placement applications on parts with features difficult for the LLT machine to negotiate, such as tight corners and curved recesses. “So, we’ve moved away from LLT technology and designed a system compact enough to fit on the head, with plenty of mold clearance and without impacting the head’s functionality.” Further, the sensor is close enough to the part to ensure accuracy of the scan and produce high-resolution images as the head moves.

Gil Lund explains that because typical off-the-shelf LLT sensors operate optimally when orthogonal, or perpendicular, to the part surface, it is almost impossible to use them on a highly curved tool surface — for example, a fuselage barrel or inlet duct part. If the angle is excessive, the laser light gets reflected away, or too much reflection is generated, a condition termed “blooming.” Both conditions make it difficult to achieve consistent, clear images.

Fives Lund’s system involves a custom sensor attached to the machine head/end effector, pointing at the part surface just a few millimeters behind the compaction roller. Gil Lund says that company has developed part program analysis software that evaluates the inspection system’s coverage, identifying any blind spots caused by AFP head path and/or part geometry constraints, without the use of overhead line templates (OLTs or laser line projectors): “Our solution,” says Lund, “has more mounting flexibility because of the increased depth of focus and reduced sensitivity to incident angle.”

Although specific public details are few, a proprietary and unique imager (not an optical camera) captures frames of the tape or fiber course as it is laid, processes that data immediately with what Fives Lund refers to as a “highly parallelized data streaming architecture” to form composite point cloud images of the part surface: “We’re using familiar concepts of processing surface profilometry data, but we have a very different way of sensing the surface, such that it doesn’t have the physical constraints of an LLT sensor,” says Gil Lund. “The way we collect and transfer the data and stitch the images together with our software, it’s happening on the fly, in real time, with fewer data, so there’s no lag. In other words, we can provide process feedback immediately, as the head lays material.”

He notes that the software works together with the AFP machine’s path-generation programming: “Not only does this system accomplish process inspection, it’s also going to improve machine cycle time. Every machine runs into problem areas, where it needs to slow down, like a tight curve, or a surface contour that is troublesome — we can analyze that now and improve cycle-time performance because the inspection sensor is giving you constant feedback so that you can adjust the CNC path in those problem areas.”

Fives Cincinnati’s director of technical sales Robert Harper says, “There are many inspection systems out there, but ours, mounted on the head, truly provides real-time information on whether the course is good or bad, during operation, so we can stop the machine and adjust or re-lay the course, rather than laying a 50-ft [15.2m] course and finding out, after the fact, that it’s bad, and has to be pulled off and discarded.”

This next-generation inspection system is being evaluated first for retrofitting to existing Fives Viper machines. “It also will be installed natively on new Fives AFP and ATL equipment,” says Harper.

Multi-application inspection

At Apodius, inspection technology revolves around its first-generation Vision System 2D, an optical system for fiber orientation measurement and defect detection, qualified for fully automated inline and stationary offline inspections. In a manufacturing workcell, for example, in which fabrics or tapes are cut, then shaped into a preform, the system can capture the preform’s surface texture with a high-resolution, camera-based system. Up to three fiber orientations can be automatically detected, measured and analyzed by the Apodius Explorer software. Fiber orientation can be measured to 0.1° resolution by evaluating the recorded raw image data of the surface texture compared to the textile’s actual design, including woven, noncrimp and braided fabrics. The system enables statistical process control (SPC) for release of preforms into production, and it is in use in several large-scale production lines.

The Apodius Vision System 2D system also can be used to repair finished carbon fiber composite parts. Because it can detect fiber orientation on the surface of consolidated parts, it can, in combination with a laser ablation cell, provide self-regulating, layer-by-layer repair preparation. As the laser ablates or removes each composite layer in the repair area, the image processor provides a record of the position and fiber orientation of the repair area. Use of the 2D data can enable economical repairs of small or partial defects in components and thus and avoid replacement of entire components.

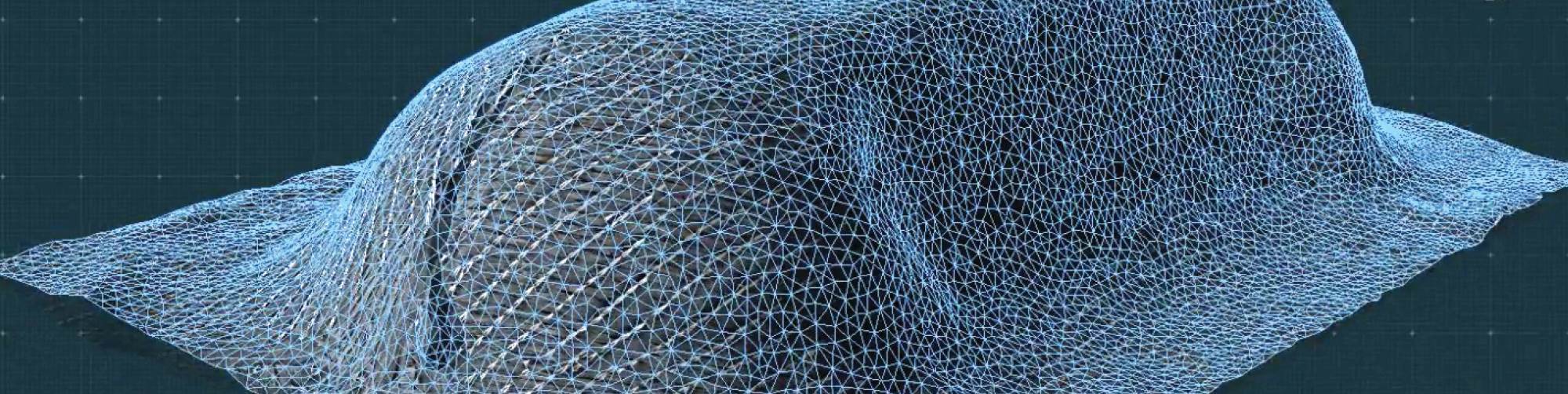

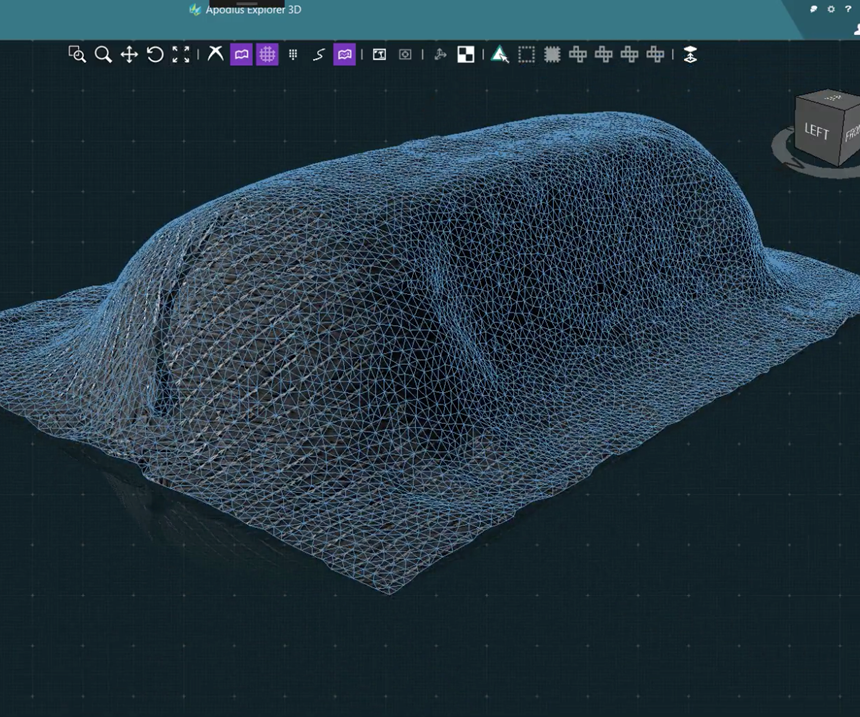

With the addition of a ROMER Absolute Arm (also made by Hexagon Manufacturing Intelligence, and fabricated from carbon fiber composites), the HP-C-V3D Apodius Vision System can collect three-dimensional image data. The ROMER Arm serves as a global reference system and determines the positional relation between part, arm and sensor head. The ROMER Arm scans the part with a laser scanner to generate a point cloud and determine the surface geometry, then the camera vision sensor configured with LED lighting captures images of the surface. Position data from the sensor plane and part surface enable the allocation of image information to a position on the part’s surface, and the image and geometric information are assembled, or stitched together, by the software program to form a digital model of the part, to document fiber orientation and detect possible defects, enabling cost reduction for composite production lines.

Evaluation of measured results is performed by Apodius Explorer software, which visualizes the measuring process in real time and analyzes results. Tools available to the user enable defect detection and part analysis as well as an actual-to-target value comparison with previously digitized master parts. Further, measurement results can be exported for iterative simulation and design purposes. For example, Apodius can verify draping simulations using as-measured fiber orientation data. Fiber and geometry data are exported directly into Digimat software from MSC Software (Santa Ana, CA, US, also a Hexagon company) for finite element analysis, to predict the part’s mechanical performance.

Related Content

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreCorebon, Composite Braiding partner to enhance TPC manufacturing

Collaboration aims to overcome production limitations with tubular thermoplastic composites (TPC) by using induction-heated tooling and high-quality commingled braids.

Read MoreNoble Gas Systems 350-bar conformable pressure vessels pass HGV2 standard tests

Conformable tanks with new materials pass technical tests for hydrogen storage, to compete with Type IV pressure vessels using CFRP.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More