In-orbit-deployable radar dish

Aramid/PEI delivers flexibility, strength and precision for space-based reflector

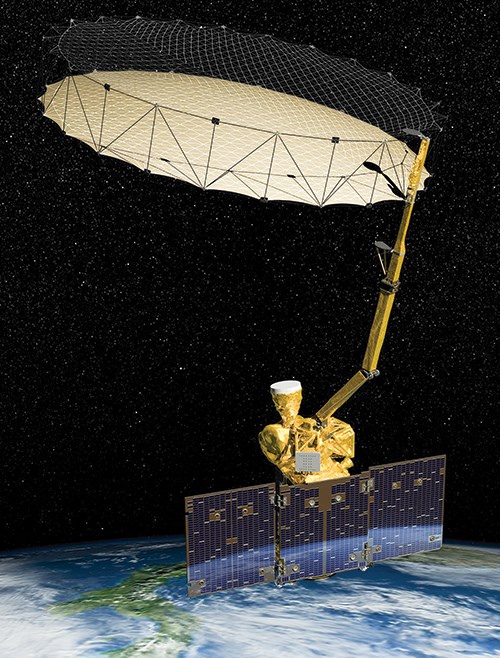

A manufacturer of deployable space structures since 1958, Astro Aerospace Northrop Grumman (Carpinteria, CA, US) has a long history with composites. Its latest project, a radar dish that enables global soil moisture measurements from the Soil Moisture Active Passive (SMAP) observatory, was launched by NASA’s (Washington, DC, US) Jet Propulsion Laboratory (JPL, Pasadena, CA, US) on Jan. 31, 2015.

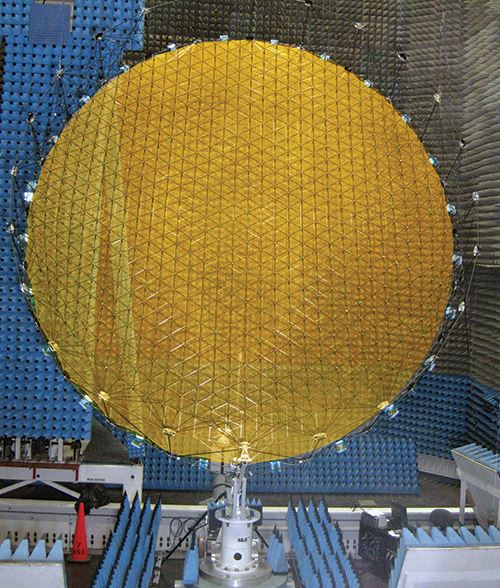

The SMAP AstroMesh dish comprises a circular carbon fiber-reinforced plastic (CFRP) truss with a metal mesh stretched across it, like a drumhead. The taut mesh reflects the microwave energy used to take SMAP measurements.

Hundreds of aramid-reinforced polyetherimide (PEI) tapes support this mesh. Pultruded by TenCate Advanced Composites (Morgan Hill, CA, US), the webs, some as long as 6m, were welded together to form a lattice of triangular facets, which gives the mesh its parabolic shape, stiffness and structural properties.

Notably, the complete structure must be collapsible. “Because there is only a finite amount of room on a rocket,” explains Astro Aerospace product development manager Daniel Ochoa, “you want to compact the structure and then open it up, once in orbit.” The AstroMesh antenna, therefore, had to transform from a 0.3m diameter by 1.5m tall structure during launch to its full 6m diameter upon deployment. Analysis manager Michael Beers says the thermoplastic composite material offers “a good balance between flexibility, allowing us to stow the webs, and deployed stability and stiffness.” The fiber-reinforced tapes use Twaron T2200 aramid fiber (2,420 dtex), supplied by TEIJIN ARAMID BV (Arnhem, The Netherlands), and Ultem 1010 PEI from SABIC (Pittsfield, MA, US).

“Most aramid-reinforced PEI is produced in tapes, which are then used in a secondary process, like filament winding or overwrapping,” says Ochoa, “but we use it right off the production line.” He notes this material was chosen because of its unique combination of the desired strength, stiffness, coefficient of thermal expansion and coefficient of moisture expansion and the necessary consistency.

“The tapes define the parabolic shape of the reflector surface, which forms the beam that scans the earth,” explains Beers. “This is why it must be so stable and consistent. The aramid fiber offers high stiffness and strength, plus withstands the temperature of our post-processing.” The webs are reinforced at their intersections by ultrasonic welding, made possible by use of a thermoplastic. Ochoa says the PEI also wet out the aramid fiber well.

Ochoa says this is the tenth AstroMesh deployable dish to successfully deploy in orbit. Previous dishes have been as large as 12m in diameter, but were used on commercial satellites as RF antennas. This, he says, is the first for a science mission and, suspended on a 3m-long boom, also made using TenCate composite materials, the first deployable spinning reflector. “This arrangement,” says Ochoa, “allows it to spin at 15 rpm and scan the whole earth in 2-3 days.” The SMAP reflector is also a low-mass AstroMesh Lite version, weighing in at a mere 25 kg — the system with boom totals 58 kg. “Mass is very important for most spacecraft applications,” Ochoa notes. “We had to provide very good mass data on all of the parts, performing a thorough survey, down to weighing nuts and bolts.” Beers also points out that because the reflector is larger in size than the spacecraft itself, “its mass and balance is critical to avoid the ‘tail wagging the dog’ in orbit.”

Ochoa says TenCate provided consistent, high-performance materials with a very high yield for each of the contracted production runs of this custom-made product. This also helped in the complicated deflection predictions that were required to ensure the reflector dish’s performance. “We had to predict the exact orientation and shape of the reflector, which is already difficult just for a stationary dish in orbit at zero gravity,” says Beers. “But we also had to account for the deformations in the structure and mesh due to spinning, including how much the boom will deflect with the mass and spin of the dish and how the reflector reacts as a result.” JPL claimed in the end “fantastic agreement with predictions.” Astro Aerospace Northrop Grumman says it looks forward to using thermoplastic composites in future deployable space structures.

Related Content

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More