Industrialized continuous fiber composite printing in Delft

CEAD offers large builds with speed, precision, low-cost extrusion and continuous fiber.

3D printing of continuous fiber-reinforced composites continues to expand and advance. Many new companies and developments have emerged since Markforged announced the Mark One continuous fiber 3D printer in 2014. I have blogged on many of these, and I will continue to explore the rapidly developing landscape and players for CW readers.

CEAD (Delft, Netherlands) was introduced in Karen Mason’s March 2019 feature, “Moving continuous-fiber 3D printing into production”. In this blog, I give more details based on my interviews with co-founder Maarten Logtenberg, including why the company sells its extruder separately and the company’s vision for the future of continuous fiber printing.

Printing with and without continuous fiber — in the same print

Along with Logtenberg, CEAD was founded by Lucas Janssen. They were half of the team that started the Dutch 3D printer company Leapfrog. “We’ve made a lot of different 3D printing machines for the industry,” says Logtenberg. “I was looking into the market and felt like printing on a large scale with materials suitable for truly industrial applications was missing. You need more strength vs. thermoplastic alone.” This is what printing with continuous fiber delivers. “So, we developed our own technology, which we have patented,” he continues.

“We still see a need for prints with short fiber and without fiber.” This is why CEAD’s Continuous Fibre Additive Manufacturing (CFAM) technology enables printing with continuous fiber and with direct extrusion from unreinforced or short fiber-reinforced pellets within the same print. “We don’t need to change the print head,” Logtenberg explains. “We put the continuous fiber in the middle of the melt, so both are extruded at the same time. But they use different drive systems. The continuous fiber is pushed through the print head but pre-impregnated to ensure quality.”

Already standard in injection molded and overmolded composites, as well as compression-molded direct long fiber thermoplastic (DLFT) composites, direct extrusion of pellets/granulated materials is cheaper for industrial production, says Logtenberg. “These materials must be dried pre-print, and we developed our own drier, which is connected to the CFAM machine.”

Similar to overmolded thermoplastic composites, for each print, the same polymer is used in both the pre-impregnated continuous filament and the unreinforced or short-fiber-reinforced direct extrusion. The company has processed a wide range of polymers, including ABS, PC, PEEK, PET, PLA and PP. They are now exploring PEKK and low melt PAEK.

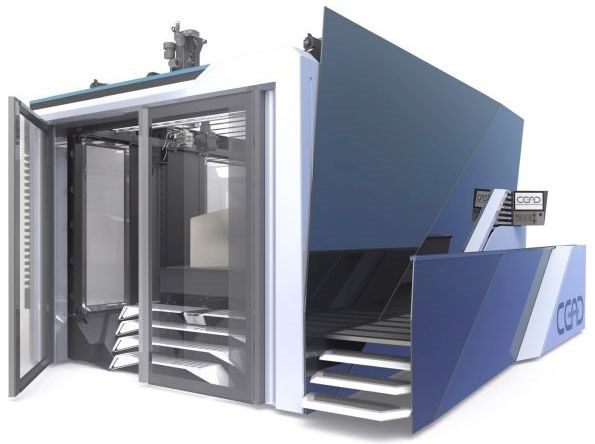

CEAD offers a smaller extrusion head for robotic arms (top) and its CFAM Prime (bottom) gantry-based machine with a 4m x 2m x 1.5m build volume.

SOURCE: CEAD

Heating zones and gantry vs. robot

Currently, CEAD offers the Robot extruder, featuring four heating zones, and its gantry-based CFAM Prime machine, with a build volume of 4 by 2 by 1.5 meters and 10 heating zones in the extruder. “We started development in 2017,” says Logtenberg. “The print head is based on a single screw extruder commonly used with injection molding. You need zones to gradually heat the material so that you can apply the great amount of pressure needed (50-60 bar) to extrude so much material. The pellets are transferred to the barrel, where they melt, then you compress and push. If you heat too fast, no pressure will build in the extruder.”

Why sell the extruder/print head separately? “Customers also wanted a smaller extruder for a robotic arm to build their own machines, but not using continuous fiber, just direct extrusion,” says Logtenberg. Then why use a gantry for the CFAM Prime? The short answer: accuracy and speed. “Robots are really good at relative accuracy,” he explains, “but the way they arrive at point B from point A is inaccurate. With 3D printing, you have to move continuously with accuracy to create a high-quality, finished part.”

“The other issue is speed,” he continues. “We wanted a high output for industrial production but also with high resolution. A robotic arm using our extruder can move at 4 m/min, which is very fast for a robot, but the gantry machine can move at 60 m/min.”

Although the gantry offers speed, an extruder on a robotic arm still offers multi-axis printing. “We are interested in using multi-axis printing to overcome the current challenge with z-direction properties [typical of printing in slices],” Logtenberg acknowledges. “We developed the gantry system first, but now have a new control system from Siemens that offers the same control on a robotic arm. So we are developing 5-axis machines. The gantry system is still faster, but this new system offers true multi-axis placement.” He envisions combining the two systems, similar to the configuration for 5-axis CNC milling machines.

CFAM Prime machine with enclosed chamber (bottom).

SOURCE: CEAD

Cooling and control

One of the issues in 3D printing is controlling shrinkage of the plastic matrix. Though the CFAM Prime initially used infrared (IR) heating managed with input from thermal cameras, Logtenberg concedes that this system produced uneven heating when printing complex shapes. “We still used an enclosed print chamber and are now developing a heated print bed,” he says. “This will provide more even heat, and we will still use thermal cameras to monitor and manage the system. If you print the same part twice six months apart you will have the same temperature profile and conditions within the print chamber.”

Logtenberg notes that the CFAM Prime extrudes so much material that there is a lot of energy in it. “So, it is hard to cool it quickly enough for the print to be stable. You want to cool the layers to make them stable as you print.,” he adds. How is this cooling achieved? “Using forced air, and a lot of it,” says Logtenberg. He notes that adding heat in the print bed and enclosed print chamber is part of controlling warpage. “You are laying hot layers on top of cool layers. But you want to keep the material above its Tg, which is more than 150°C for some materials, yet it’s stable to print on top of.” Even with this process, Logtenberg notes there will always be some thermal stress in the part. “You can do some post-process steps to get tension out of the part.”

Robot extruder with multiple heating zones.

SOURCE: CEAD

CEAD uses Siemens systems to control its machines. “These are well thought through and can handle complex challenges in the process and materials,” Logtenberg explains. CEAD wrote its own software behind the Siemens system to provide an easy user interface. “The machine runs on G code, which is also the standard used for industrial milling machines,” he notes. “This gives freedom in programming the parts. It can use open source slicers but also Siemens NX, which is a powerful software tool.”

Logtenberg says the customer can choose how complex he/she wants to go. “Our approach is very open source, enabling different kinds of print software to be used. So if the customer wants a very simplified print, you just press a button. But it is also possible to use more advanced software. However, then the customer must have the knowledge on how to use this. Our vision is to let people decide what they want to use and then we support them.” Logtenberg notes that CEAD is selling to businesses, not to consumers. “So we have the ability to provide more support.”

Printed parts and properties

“You can feel the difference in parts printed with continuous fiber versus those printed with chopped fiber,” notes Logtenberg. “But we have not tested properties yet.” That is the next task, now that machine development and initial launch have been completed. “This year we will work on fully characterizing the materials and developing data sheets with compression strength, stiffness, etc. for each material combination,” he adds.

Determining void content and fiber volume is also part of this characterization work. “Our fiber content is not that high at the moment,” concedes Logtenberg. “If you’re using the chopped fiber pellets, you have 30% fiber by weight, for example. Adding the continuous fiber only adds another 10% to this because the overall output and volume is large.”

What about compaction to reduce void content? “The nozzle itself is compacting the layer,” says Logtenberg. “You must have the right layer height versus width. If you have that right, you get good adhesion between the layers.” He explains that the ratio of height to width should be in the right range to allow compression force in the printed layer and enough heat to get good fusion in the layers. “For example, in a printed layer 5-mm-high and 5-mm-wide, there will be almost no compression force,” he notes. “For a 5-mm-high layer, you need a width of 10 mm.”

CEAD is continuously improving the CFAM Prime print quality, says Logtenberg. “We have developed a lot of internal software for dynamically printing.” He explains there were problems in the corners because the extruder is pushing out material while the machine must slow down to turn direction. “We have now solved that problem. We keep developing our tracking using sensors, the dynamics and the layer temperature, for example, to improve process control.”

Printing complex shapes with CFAM Prime.

SOURCE: CEAD Instagram, March 2019

Machines for marine and construction

Logtenberg says the first targets for CEAD Prime’s industrial production capacity are the marine and building & infrastructure markets because its printed composite parts are good enough to be directly used for end service. Indeed, its first customers are Royal Roos (Rotterdam, Netherlands), a marine engineering and construction firm, and Poly Products (Werkendam, Netherlands), a composites fabricator that works in the marine, architecture, industrial, recreational and transportation sectors.

That being said, the CFAM Prime is also being used to print molds, especially for marine structures. “This is why we proceeded with the robotic arm,” says Logtenberg, “and we have added CNC milling, much like the LSAM machine [by Thermwood] but a little smaller and less expensive.”

“In the EU, the build rate for marine is down,” he says. “Because the labor is so expensive, the production goes to China. So, we are trying to establish a way to compete. We are also looking at other markets, like automotive, aerospace and other transportation.”

The response in the marine and construction market has been good. “We’re doing a lot of projects to show what the machine can do,” says Logtenberg. “After the launch last fall, sales were slower than we would have liked. But now it is moving well, with accelerating projects and machine developments.”

For these new markets, CEAD is exploring new materials. For example, it is testing a material from SABIC for fire resistance and talking to train manufacturers. With the ability to print continuous fiber, could CFAM also be used to print with wire and/or sensors? “We are looking into this,” says Logtenberg. “We are working with a company to embed steel fiber, which is also conductive.”

Future vision

Many in the traditional composites industry are questioning how 3D printed continuous fiber composites can compete with conventional composites when they have such low fiber content and such high potential for delamination between the printed layers. “For sure, z-direction strength is one of the most challenging things for 3D printed composites,” Logtenberg agrees. “We aren’t competing with conventional composites currently. We believe that in the future we will be able to compete with conventional composites because our production is completely automated, but we have a long way to go. Right now, it’s an addition to current manufacturing methods, giving flexibility and opening design and production possibilities.”

The CFAM Prime machine at its launch in 2018.

SOURCE: CEAD

Related Content

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)