Innovation in SMC: A long history and great potential

Manufacturer’s representative Steve Brown reflects on the history of sheet molding compound (SMC) development and lessons he has learned from working with companies through the process.

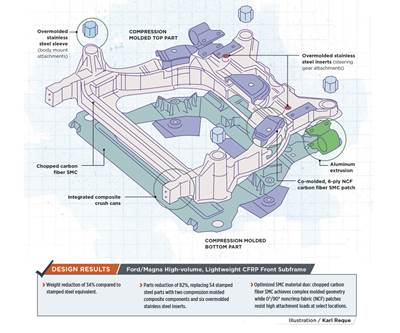

CW’s Aug 2018 article (“Teaming to define what CFRP could be”) on the CFRP front subframe developed by Ford Motor Co. (Dearborn, MI, US) and Magna International (Aurora, ON, Canada) illustrates innovation in sheet molding compound (SMC) — specifically, overmolding noncrimp carbon fiber fabric SMC with chopped carbon fiber SMC. This idea of using a continuous fiber SMC comolded with conventional chopped fiber SMC, and the use of chopped carbon fiber SMC, may seem brand new, but these innovations actually go back more than 30 years to the GMC Astro Class 8 truck door using SMC developed by Premix/EMS. Several other projects contributed further developments over the years. This history of SMC development shows how far the industry has come, but also that the future belongs to those who understand the big picture, and thus, are willing to take risks.

The GMC Astro Class 8 vehicle door was one of the parts that impressed me the most when I joined the industry in 1986 as a technical sales representative for Premix/EMS (North Kingsville, OH, US). A heavy truck fleet owner even remarked that the SMC door was the best thing about that truck. The three-piece assembly had inner and outer structural parts with a decorative cover panel. But I was most impressed with the addition of continuous unidirectional material in the window frame area. It was an example that I used often when a vehicle design engineer needed higher tensile strength than what our conventional discontinuous fiber materials offered.

My lesson learned: A vehicle designer considering development of a co-molded part must have enough confidence in all phases of part development to know whether he or she is creating a breakthrough, or just another science experiment.

The Next Step

In 2003, the Dodge Viper represents the first use of carbon fiber SMC in a production vehicle.[i] The vehicle manufacturer Chrysler and the SMC supplier Quantum Composites (Bay City, MI, US) developed breakthrough solutions in three structural systems:

- Thin-walled sections in fender supports,

- Carbon fiber SMC and low-density glass fiber SMC in door panels,

- Co-molding unidirectional carbon fiber with structural SMC on the windshield surround.

In a 2002 paper published by the Society of Plastics Engineers (SPE, Bethel, CT, US), the development engineers at Chrysler and Quantum cite lack of understanding carbon fiber as one of the key factors limiting prior use of it in SMC. I think another key issue was the need to understand how randomly oriented fibers behave in structural applications. Material suppliers, molders and design engineers had decades of experience in making thermoset fiberglass-reinforced plastic structural parts. They were accustomed to these being stronger than thermoplastics, using materials with clear data sheet values, and if you needed more strength, you could just add material. The parts were characterized by long-term resistance to creep, which insured that structures remained in place under stress. But the SMC industry was not ready for the examination that Boeing would conduct into discontinuous fibers.

New Challenges

As the Boeing Co. (Chicago, IL, US) developed its 787 Dreamliner commercial aircraft, it began looking at a variety of new materials, including Hexcel’s (Stamford, CT, US) HexMC chopped carbon fiber/epoxy material. The push at Boeing to use this material for primary structure created a need for a deeper characterization of discontinuous fiber performance, including understanding the variation and predictability of SMC. This was the type of data and analysis the industry was ill-prepared to provide.

To understand the answers to Boeing’s questions, I went to a source who had already done much of the investigative work: Dr. Paolo Feraboli at the Automobili Lamborghini Advanced Composite Structures Laboratory (ACSL) created with the University of Washington (Seattle, WA, US). Much of his work can be summarized in the 2009 paper “Notched behavior of prepreg-based discontinuous carbon fiber epoxy systems”.[ii] Feraboli’s work helped the industry understand the underlying principles of coupon and part testing, and provided insight into why parts worked and the limits to assumptions from coupon test values alone. A summary of similar work was presented at the 2013 SPE Automotive Composites Conference & Exhibition (ACCE) by Matt Kaczmarczyk and Tim Langschwager of Quantum Composites.[iii] This gave Quantum the data and confidence that we not only understood our materials but could explain their performance to others.

Performance at The Next Level

As head of the ACSL, which was seeking cross-pollination between aerospace and automotive composites, Feraboli had performed testing and development work on the Sesto Elemento, the first Lamborghini model to use CFRP not only in its monocoque, but also in its suspension control arms. The Sesto Elemento also pioneered application of carbon fiber SMC in both of these applications. This development was in parallel with Callaway Golf Co.’s (Carlsbad, CA, US) use of the material for driver crowns (golf club heads) and Quantum Composites’s AMC 8500 family of chopped 12K carbon fiber/vinylester resin products. Both Lamborghini and Callaway were seeking to expand the limits of performance and practical part size. The Sesto Elemento’s suspension arm actually used unidirectional carbon overmolded with carbon fiber SMC, one of the first commercial applications of the material.[iv]

Lessons Learned

Material suppliers and creative design teams have shown that co-molded hybrid material parts are the future. There is a thirty year history of product development and refinement of engineering techniques which have countered earlier challenges. But from my experience, the breakthrough needed to move forward will not be the engineering, it will be in the management of the innovation process by material suppliers and OEMs.

One example of these challenges can be seen in the Ford Magna project. Design simulation of SMC has made great strides from approximating values based on standard shapes. The Ford Magna project required a coordination of four types of software. Having a single integrated platform that will go from part design to mold flow will greatly assist all involved.

In addition, SMC producers are good at making a wide range of very similar products. Making a “structural product” is different than making a good consistent SMC. Small amounts of variation in proven or new products can turn into problems when the upper ends of mechanical properties are pushed. This puts a premium on process control and material characterization to create confidence in a material for the design team.

Experience has shown me that little things kill projects. Too many secondary operations can add significant cost. The inability to control a small occasional warp in a key fit area or the need to prime paint can derail a project with great design breakthrough.

Overall, the question I would ask any team in the process of innovating with SMC: did you find moving forward was a great and rewarding experience or have you gone back to what you know and you do well? From my experience, the challenges of pushing the limits can create a mental cloud that can be tough to overcome. However, as these parts have illustrated, moving fast with conviction to make a better product can result in success.

Editor’s note: Premix and Quantum Composites were acquired in 2011 and combined with Hadlock Plastics (Geneva, OH, US) to form The Composites Group (Kingsville, OH, US), but operate as individual suppliers. The Composites Group was acquired by Citadel Plastics (Chicago, IL, US) which, in turn, was acquired by A. Schulman (Fairlawn, OH, US). LyondellBasell (Rotterdam, The Netherlands) acquired A. Schulman in August 2018.

ABOUT THE AUTHOR

Steve Brown has worked as a manufacturer’s representative for Premix and Quantum Composites, selling composite materials and molded parts to aerospace and automotive OEMs since 1986. He has spent much of that time developing new applications for high-performance SMC in aerospace, automotive, recreation and industrial markets. He has promoted co-molding of complex 3D geometries with woven and discontinuous fiber materials and will continue introducing design engineers to new and unique methods to solve problems where conventional composite materials struggle.

References

[i] https://www.quantumcomposites.com/pdf/papers/Viper-SPE-Paper.pdf.

[ii] https://www.researchgate.net/publication/229255007_Notched_behavior_of_prepreg-based_discontinuous_carbon_fiberepoxy_systems.

[iii] http://www.temp.speautomotive.com/SPEA_CD/SPEA2013/pdf/CF/CF3.pdf.

[iv] http://www.lambolab.org/wp-content/uploads/03research/pub/05chop/2011-ASC-montreal-forged-suspens-ICE.pdf and https://www.compositesworld.com/articles/sixth-element-lamborghini-accelerates

Related Content

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreRead Next

Teaming to define what automotive CFRP could be

Ford and Magna explore a high-volume chassis front subframe build from co-molded chopped fiber and noncrimp fabric SMC.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More