Is 3D commuting in our future?

As we look to the skies in an effort to alleviate traffic jams on the ground, might there be a future for composite materials in emerging aircraft ride-sharing?

Rendering of CityAirbus vehicle. (Source: Airbus Group)

Rare is the person who, sitting in a vehicle stuck in traffic, hasn't looked to the sky and wondered why we can't simply fly to work or the grocery store or the movie theater. Why, as we move around our cities and towns, are we restricted to the two-dimensional space of highways and roads?

Of course, the answer is simple: Multiple flying crafts in the airspace over a city is a recipe for disaster. We humans are pretty good at following the rules of the road easily enough and have, remarkably, few accidents to show for it. But fighting gravity in a three-dimensional space with hundreds or thousands of other craft fighting gravity in a three-dimensional space is an order of magnitude more complicated.

Still, there is no shortage of science fiction books and movies that do this very thing, and it's highly appealing. The question is, might we actually do it one day? Well, Airbus says yes, it's feasible.

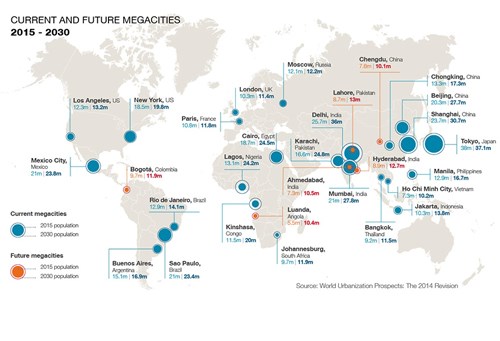

What drove Airbus to explore this idea is the fact that, by 2030, 60% of the world’s population will live in cities, which is 10% more than today. And, as population density increases, so does vehicle traffic. For example, in Sao Paulo, Brazil, one day in 2014, the rush-hour traffic stretched out for 344 km. According to a study, these huge back-ups in Sao Paulo cost the Brazilian economy at least US$31 billion a year. Another study found that Londoners lose the equivalent of 35 working days per year idling in traffic.

Megacities, now and in 2030. (Source: Airbus Group)

In response, Airbus Group's A3 organization, the company’s innovation outpost, is pursuing a project coined Vahana, an autonomous flying vehicle platform for individual passenger and cargo transport. Flight tests of the first vehicle prototype are slated for the end of 2017. As ambitious as that sounds, Rodin Lyasoff, project executive, insists that it is feasible: “Many of the technologies needed, such as batteries, motors and avionics are most of the way there.” However, Vahana will likely also need reliable sense-and-avoid technology. While this is just starting to be introduced in cars, no mature airborne solutions currently exist. “That’s one of the bigger challenges we aim to resolve as early as possible,” says Lyasoff.

Transport service providers are one target group for such vehicles. The system could operate similarly to car-sharing applications, with the use of smartphones to book a vehicle. “We believe that global demand for this category of aircraft can support fleets of millions of vehicles worldwide,” estimates Lyasoff.

At these quantities, development, certification, and manufacturing costs go down. And in terms of market entry, Lyasoff is equally confident: “In as little as 10 years, we could have products on the market that revolutionize urban travel for millions of people.” A3 is powering ahead with Vahana and as is typical for Silicon Valley, the company thinks in terms of weeks, not years. Officially underway since February 2016, the project’s team of internal and external developers and partners have agreed on a vehicle design and is beginning to build and test vehicle subsystems.

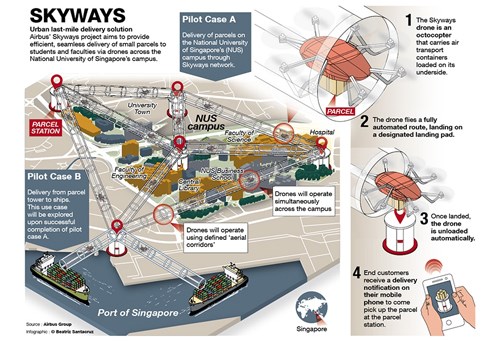

The challenge of flying autonomous vehicles over urban areas is summed up neatly by Bruno Trabel from Airbus Helicopters: “No country in the world today allows drones without remote pilots to fly over cities – with or without passengers.” The engineer leads the Skyways project, which aims to help evolve current regulatory constraints. In February, Airbus Helicopters and the Civil Aviation Authority of Singapore (CAAS) signed a memorandum of understanding allowing Airbus Helicopters to test a drone parcel delivery service on the campus of the National University of Singapore in mid-2017.

National University of Singapore will the the site of autonomous parcel delivery technology.

(Source: Airbus Group)

Parallel to the Vahana effort, for the last two years Airbus Helicopters has been working on an electrically operated rotorcraft platform concept for multiple passengers. The aerial vehicle, which goes by the working title of CityAirbus, would have multiple propellers and also resemble a small drone in its basic design. While initially it would be operated by a pilot – similarly to a helicopter – to allow for quick entry into the market, it would switch over to full autonomous operations once regulations are in place, directly benefitting from Skyways and Vahana’s contribution.

With CityAirbus, customers would use an app to book a seat on a craft, proceed to the nearest helipad, and climb aboard to be flown to their destination. Unlike Vahana, several passengers share the aircraft. The sharing economy principle would make journeys in the CityAirbus affordable. A flight would cost nearly the equivalent of a normal taxi ride for each passenger, but would be faster, more environmentally sustainable and exciting.

A third concept, called zenAIRCITY, created by Vassilis Agouridas and co-developed by Benjamin Struss – both from Airbus Helicopters – envisions a quiet, electrically operated aerial vehicle that is completely integrated into the infrastructure of a megacity. Possible platforms could include Vahana or CityAirbus. At the heart of their vision is a whole range of products and services, encompassing everything from flying taxis and luggage services to cyber security. The goal? Offering passengers a seamless travel experience.

Related Content

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More