JEC WORLD 2022 highlights

Fast-cure prepreg and AAM materials

Solvay Composite Materials (Alpharetta, Ga., U.S.) emphasized on its stand SolvaLite 714, a fast-cure epoxy prepreg targeted toward automotive applications. It features a long shelf life and long process window and, Rob Blackburn says, head of customer engineering (EMEA), offers a 10-minute cure cycle.

Dominating the center of the Solvay stand was a model of the VX4, Vertical Aerospace’s (Bristol, U.K.) advanced air mobility (AAM) aircraft, which is in development and features aerostructures made with Solvay materials. Sam Hill, UAM market manager at Solvay, says Vertical Aerospace expects to fly a prototype of the VX4 during summer 2022 and that the company is already working with Solvay to develop next-generation materials for future aircraft. The key, Hill says, will be to “future proof” the aircraft with automation, out-of-autoclave (OOA) processes and thermoplastic materials.

Solvay also reiterated its January 2022 announcement that it and Trillium Renewable Chemicals (Birmingham, Ala., U.S.) have signed a letter of intent to develop the supply chain for bio-based acrylonitrile (bio-ACN). Trillium will supply Solvay with bio-ACN from Trillium’s planned commercial asset, and Solvay will evaluate bio-ACN for carbon fiber manufacturing as part of its long-term commitment to developing sustainable solutions from bio-based or recycled sources. The aim of this partnership is to produce carbon fiber for use in various applications such as aerospace, automotive, energy and consumer goods.

Specialty thermoplastic fabrics

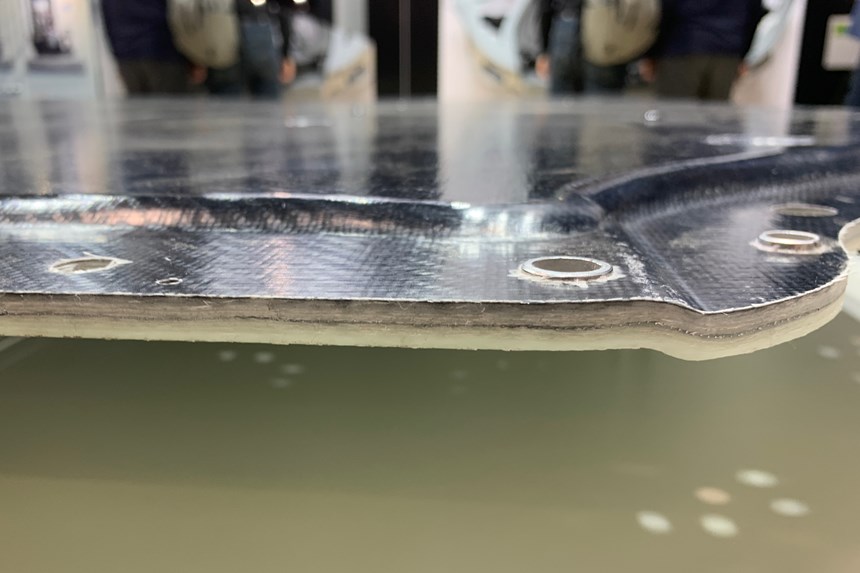

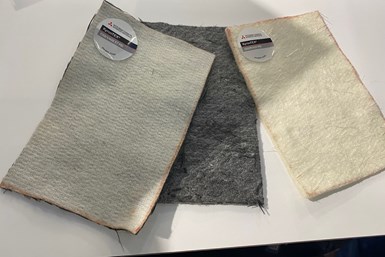

Mitsubishi Chemical Advanced Materials (MCAM, Wischhafen, Germany) brought to JEC a new line of products containing continuous fiber and random fiber reinforcements (such as fabric, chopped CF, GF and rCF). Emphasized was

the KyronTEX line of fabrics, available in two varieties. KyronTEX C/44/R is a nonwoven that combines PP, PA, PEI, or PPS with recycled carbon fibers (rCF). It’s available in a variety of areal weights and in widths up to 2.4 meters. KyronTEX C/55/1 is reinforced with continuous fibers (in this case with woven fabric).

Beside fabrics, MCAM’s new continuous fiber products can be produced with unidirectional (UD) or NCF with carbon fibers or glass fibers in the core, surrounded on each side by a polymer fleece of PA, PC, PEI, or PPS. It’s available in areal weights of 300-700 gsm. KyronTEX continuous fiber products are flexible thermoplastic “prepregs” allowing excellent drapability and easy handling since continuous reinforcement fibers are fixed within the polymer fleeces and thus do not disorient during handling.

MCAM also reported using KyronTEX in a compression molding process to fabricate high-porosity, thick laminates. This was done by gapping the mold, thus allowing the material to loft. The finished product has the look and feel of a sandwich structure and can be molded directly from fleece to laminates or shaped parts. Thickness of the laminate can be varied and, although the weight of the structure is greater than a comparable honeycomb panel, MCAM says the processing time of the lofted material is shorter. Research on the process is ongoing, but MCAM says potential applications include long boards, panel vans, aircraft interiors, e-mobility structures and electric vehicles (EVs).

Sustainable sporting goods, prosthetics, automotive specialty applications

Cobra International (Chonburi, Thailand) is likely the largest and best known composites manufacturer in Thailand and reported at JEC that the pandemic, which drove people to spend more time outdoors, helped the

company double its revenues since 2019. Danu Chotikapanich, CEO of Cobra, says much of the company’s focus has been on electrification of outdoor products and development of foils for watersports structures. This includes development of a wing for wing foiling and a windsurfing foil and fabrication of a recycled/recyclable surfboard, made with offcuts from Cobra’s automotive operations. Cobra is also fabricating <10-meter wings for unmanned aircraft systems (UAS), as well as structures for mapping drones. In the medical market, Cobra is working with Chulalongkorn University in Thailand to develop carbon fiber foot prosthetics for people injured in motorcycle accidents. Cobra’s automotive manufacturing operations, called Cobra Advanced Composites (CAC), employs 600 people in a 10,500-square-meter facility. Michael Roeffaers, managing director of the operation, says CAC focuses heavily on fabrication carbon fiber composite parts, with natural fiber reinforcement offered/applied where possible, for automotive OEMs. Emphasis is on helping automakers meet sustainability goals through use of renewable and CO2-friendly materials. Roeffaers had on hand at the show several side-view mirrors made by CAC with flax fiber reinforcement.

Recycled carbon fiber thermoplastic 737 sidewall panel demonstrator

Cannon Group revealed at JEC that its Cannon Ergos (Caronno Pertusella, Italy) unit has completed fabrication of a demonstrator 737 sidewall panel made with recycled carbon fiber and a thermoplastic resin system for Boeing (Chicago, Ill., U.S.). Cannon Ergos did the mold build, material characterization and trials were performed on a Cannon press using compression molding. For the wind energy market, Cannon Afros reported that it has provided a wind blade manufacturer with its newand enhanced Direct Infusion process. With this system, several infusion gates can be managed by the dosing and mixing machine, with each gate independently and directly controlled, but fed by the same dosing group. Cannon Afros says this enables precise control of resin injection at specified ratios, flowrates and pressures in strategic locations. Further, the system allows resin injection to exploit the pressure given by the pumping system and not only by the mold vacuum, which expedites infusion. Cannon Afros says that the system is already used for blade production to infuse epoxy. Cannon Afros reports that the Direct Infusion system can work with all the most common resin matrix.

Hexcel outlook on sustainability, hydrogen, AAM

Thierry Merlot, Hexcel (Stamford, Conn., U.S.) president – Aerospace for Europe, MEA/AP & Industrial, sat down with CW at JEC to talk about carbon fiber and composites materials for established and emerging markets. He begins by noting, as many others did at JEC, the “sustainability wave” that is washing over the composites industry. “This is very important to the industry we serve and to Hexcel,” he notes. Regarding the latter, Merlot reports that Hexcel has created an in-house committee to study the company’s sustainability position and set goals to improve it. Targets for sustainability improvement include energy use, emissions, water use, waste rates, bio-based resins, bio-based polyacrylonitrile (PAN, the precursor of carbon fiber) and recycled acrylonitrile. “In the end, this is the change we must confront: climate change,” he says.

When asked about emerging markets, it was not difficult to determine which Merlot, and Hexcel, is most excited about. “Hydrogen, for me, is the energy of the future, and for hydrogen, carbon fiber is key,” he says, noting that current hydrogen storage pressure vessels consume about 50 kilograms of carbon fiber each. On top of that, the fiber is aerospace grade, but, in Hexcel’s case, “tweaked” for pressure vessels. Hexcel, he says, is working diligently to fine-tune and optimize fiber use and resin chemistry for pressure vessels in an effort to get costs down and performance up. Does Merlot foresee need to expand carbon fiber capacity to meet demand from the pressure vessel market? “If we can demonstrate use of less fiber to achieve cost targets then, yes, expansion would be considered,” he says.

What about advanced air mobility (AAM), the other emerging market roiling the composites industry? Merlot is more reserved about the potential for growth here, but acknowledges that Hexcel is “working on several projects in this space.” The challenge, he believes, lies in the shear number of infrastructure and regulatory hurdles that must be cleared to make AAM a reality. He is also concerned about AAM’s dependence on battery power, the resources for which are in too short supply. “This market is quite a risk,” he says. “Still, there is a lot of cash and a lot of things are moving.”

Ultimately, Merlot remains optimistic about where the composites industry is headed. “The future of the composites industry has always been very good,” he says. “Now, it is great! I wish I could be 30 years younger to see how all of this turns out.”

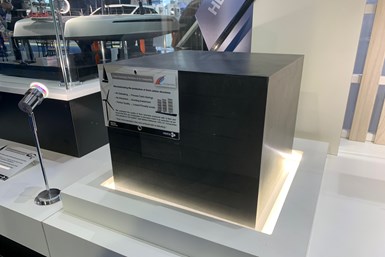

Thick-part molding without debulks for marine applications

Also featured on the Hexcel stand was G-Vent, a lightweight (3-6 gsm) grid that can be integrated into thick prepreg laminates to promote and maximize air egress for OOA fabrication. Tom James, head of Hexcel’s marine business, says G-Vent provides autoclave-like properties in a vacuum bag-only (VBO) process, but without the debulks typically required in thick-part fabrication. Further, James notes that because the density of the G-Vent grid is similar to that of the resin system itself, it is not parasitic to the structure and can actually improve mechanical properties. Hexcel had on display at JEC a 500 x 500 x 500-millimeter carbon fiber block made using G-Vent in the company’s M79 carbon fiber/epoxy marine prepreg. The 900-ply structure was bagged and oven cured at 80°C with no debulk. It has a porosity of 0.3% and weighs less than 100 kilograms. James says structures made with G-Vent are being initially targeted toward sailing masts, foils and wind-assisted ship propulsion (WASP) components.

Hexion is now Westlake Epoxy

One of the big changes in the composite materials supply chain during the pandemic was the acquisition of Hexion’s epoxy business by Westlake Corp. (Houston, Texas, U.S.), which renamed the business Westlake Epoxy. Other than that, not much has changed at the company that used to be Hexion and its stand at JEC featured the usual mix of applications from the automotive, wind, pressure vessel and other end markets. In wind energy, the most interesting technology is a wind blade repair system developed by Westlake in cooperation with DD|Compound (Ibbenbüren, Germany) that allows long-segment infused repairs on leading and trailing edges. “Long” in this case means 40 meters, which, until now, has proven difficult to achieve. Dominik Dierkes, CEO of DD|Compound, says the repair system is fully kitted and includes fabric, Westlake resin cartridges, feed lines, vaccum bag and heating blankets. The repair is built from the root end of the blade toward the tip and, Dierkes says, can be set up and infused in one day. It’s particularly effective, he says, for fatigue life repairs, such as long cracks or splits.

Jean Riviere, global segment leader for epoxy aerospace composites at Westlake, talked to CW about activity in the pressure vessels market for hydrogen storage. He notes that the M&P around hydrogen storage is dynamic and evolving rapidly, with a lot of work being done with wet filament winding, towpreg winding and resin transfer molding (RTM), all of which is compounded by carbon fiber supply shortages. Westlake, he says, has resins that are and can be used to fabricate pressure vessels. Further, he asserts that the supply chain for such materials is stable. For aerospace, Westlake launched at JEC EPIKOTE TexFix, new preform binders product. The binder is designed for large parts and complex shapes and is said to withstand the tendency to washout, which the company says is common with competing binders.

Francis Defoor, global market segment leader transportation at Westlake, pointed to two recent applications that use the company’s resin systems. The first is an RTM’d helper plate on the leaf spring suspension system for the Ford F-150. Manufactured in Mexico by leaf spring specialist Rassini (Plymouth, Mich., U.S.), the helper plate, which combines a non-crimp e-glass fiber with EPIKOTE Resin TRAC 06150 epoxy from Westlake, is molded at a rate of about 900,000 units per year. (For more information, CW covered the Rassini leaf spring here.) In addition, Westlake gave a presentation at JEC on phenolic sheet molding compound (SMC) targeted toward EV battery tray applications. Phenolic is attractive in such applications because of its thermal runaway and fire, smoke and toxicity (FST) performance.

Bigger, lighter, more affordable carbon fiber wheel

If hydrogen pressure vessels were the most commonly displayed product at JEC, carbon fiber wheels weren’t far behind, and a notable wheel was found in the Hankuk Carbon (Wokingham, U.K.) stand. Wheel manufacturer Dymag (Chippenham, U.K.) exhibited the third generation of its carbon fiber wheel. It features a two-piece fully carbon fiber rim with a metallic center. Dymag CEO Tom de Lange says the goals with the new wheel were to eliminate the bolts attaching the metallic centers to the composite rim, reduce the cost of the wheel and increase manufacturability. Achieving this has been accomplished, in part, by a manufacturing partnership with Hankuk Carbon, which provides the scale-up capabilities that Dymag needs. Dymag and Hankuk Carbon are in the process of working out location and logistics for the first manufacturing line they will develop together. Dymag has capacity to produce 2,000 rims per year currently, but de Lange expects that to increase to 4,000 rims by the end of 2022.

Going to market, Dymag is pursuing two models. First, Dymag will make wheels with rims and centers, for OEMs and the aftermarket. Second, Dymag will supply composite rims only for customers that want to design and insert their own centers (primarily Tier 1, Tier 2 and aftermarket suppliers). According to de Lange, the biggest benefits of composite wheels to vehicle performance and efficiency are inertia reduction, NVH reduction and weight reduction (40-50% compared to aluminum and magnesium). Composite wheels, de Lange also notes, are also getting larger, the same way metallic wheels are. “Shifting to a lightweight material eliminates the weight penalty of a bigger wheel,” de Lange notes. “A composite wheel is unique because it offers aesthetic and safety features.”

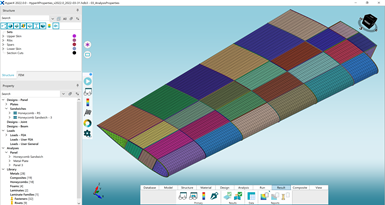

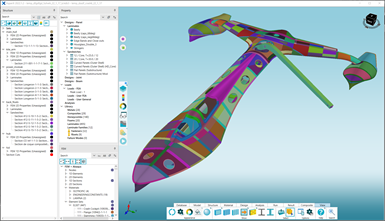

Meet the new Collier, and HyperX

Composites design software specialist Collier Aerospace (formerly Collier Research, Newport News, Va., U.S.) came to JEC with HyperX, a completely new and rewritten version of HyperSizer, the company’s legacy structural analysis and design software. Craig Collier, CEO of Collier Aerospace, says HyperX is not simply a replication of the 25-year-old HyperSizer, but a completely rethought and rewritten package designed to meet the needs of next-generation composite designs — particularly aerospace designs. Macro improvements offered by HyperX include a new underlying database, faster graphics, larger models, a new user interface and faster task-to-task workflows. More specific features and improvements include more laminate formats, traceability of computed results, simultaneous calculation of bonded and fastened joints, faster weight and schedule reduction calculations, better design for manufacturing capability and automatic updates to the finite model (using the HyperFEA utility).

Collier also says that early tests with the software demonstrated up to 10 times faster design cycle calculations between FEA and stress analysis. In the case of aerostructures, this is said to help shorten the U.S. Federal Aviation Administration (FAA, Washington, D.C., U.S.) and European Union Aviation Safety Agency (EASA, Cologne, Germany) certification process. “This allows the user to find the most robust, most responsive, least sensitive design,” Collier says.

Collier also notes that HyperX enables large-ply surface coverage with simple layouts that do not significantly increase weight but do reduce variation in build. The new software, which is licensed on a subscription basis, will replace HyperSizer, the company’s previous product. Existing customers will be invited to migrate to the new software. Collier Aerospace will continue to support HyperSizer throughout a customer’s transition to HyperX.

Autoclave consolidation quality, accelerated

Startup Atomic-6 (Marietta, Ga., U.S.) offers a proprietary technology that, it says, accelerates capability to manufacture the highest aerospace grade quality parts through the use of resin infusion in an autoclave process. This allows for faster curing cycles versus historic prepreg resin systems while providing uniform distribution of fiber and matrix, promoting polymer chain alignment, and minimizing porosity throughout the structure. President and CEO, Trevor Smith, describes the technology as providing high-fiber volume fraction parts at relatively high pressure with minimal resin content. He guards the company’s innovation carefully and will say only that it’s a physics-based (not chemistry-based) technology. Regardless of the nature of the technology, Atomic-6 is deploying it at its Georgia-based facility to fabricate composite parts and structures in a variety of applications, primarily for space and defense projects. At JEC, Smith list several, including thin-laminate, unwinding support structures for satellite solar arrays; a center wing bulkhead for a Group 5 UAS; thermal barriers for hypersonic aircraft; and a chassis for an unmanned rover.

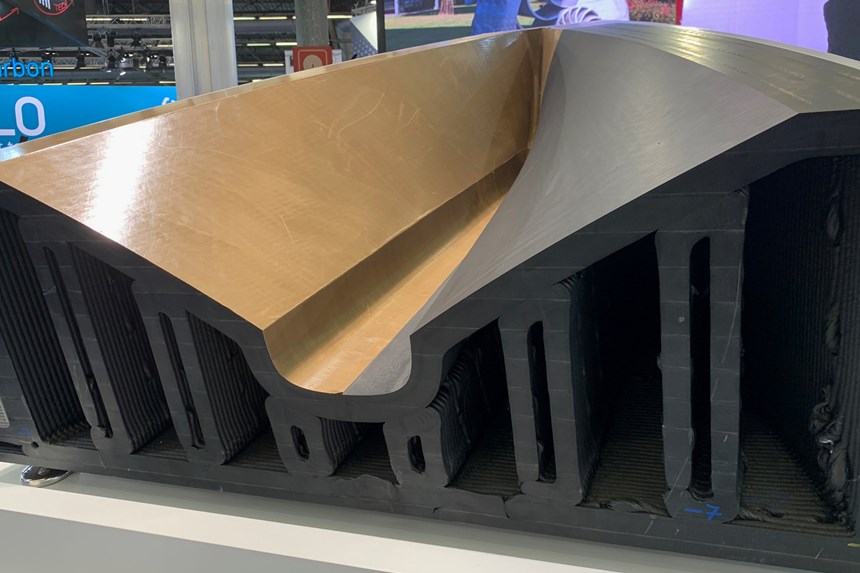

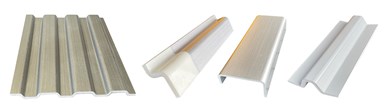

Tailored, cut carbon fiber tapes for parts, tooling

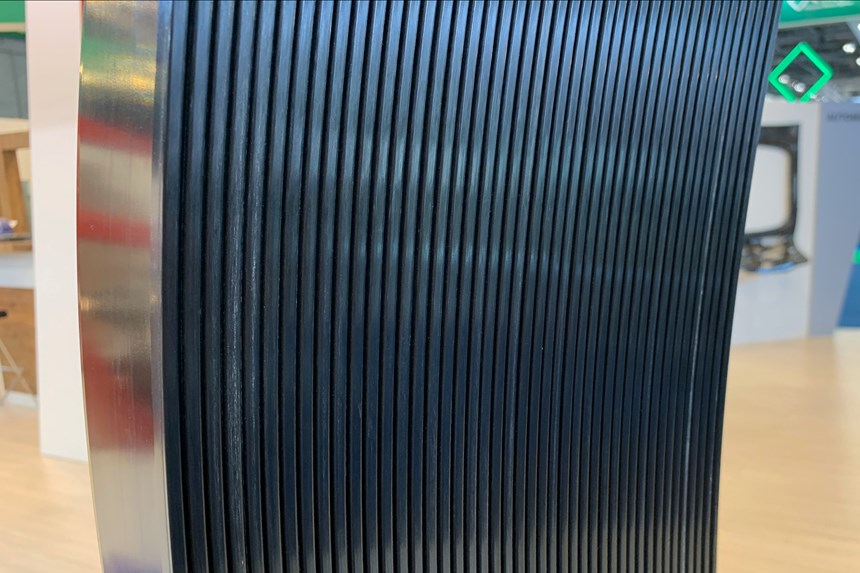

Voith Composites (Garching, Germany) made a name for itself a few years ago when it developed the Voith Roving Applicator (VRA) technology for the building of glass and carbon fiber tape stacks to fabricate preforms for the high-pressure resin transfer

molding (HP-RTM) of rear seat panels for the Audi A8. Voith revealed at JEC that it is now leveraging that technology for the production of two customer-ready products for composites fabrication and moldmaking. Carbon4Stack is a bespoke product made to customer specification and features carbon fiber tapes cut, angled and stacked for forming. For parts that need good surface quality, Voith offers a Carbon4Vistal version as well. On the tooling side, Carbon4Tool is an off-the-shelf product that consists of 300 x 300-millimeter carbon fiber tiles designed for layup to build a mold. Voith also had in its stand a carbon fiber pressure vessel for hydrogen storage. It’s manufactured by Voith using towpreg filament winding and is rated to 700 bar. Mike Bailly, head of sales and marketing at Voith, says the company is targeting “trucks, buses, trains and cars with the tanks — whatever doesn’t fly.”

Data-accelerated materials development

We talk a lot in the composites industry about the deployment of data on the plant floor to support manufacturing operations. So, it’s somewhat out of the ordinary — but logical — to learn that data and machine learning are being applied to materials development as well. Citrine Informatics (Redwood City, Calif., U.S.) came to JEC to discuss informatics and how it can be leveraged to accelerate development of polymers, metals and alloys. Stefan Keller, senior account executive at Citrine, explains that Citrine’s software takes data inputs from a variety of sources — manufacturer, simulation, process and more — and generates models than the user can then employ to optimize the material. For example, if a user wants to modify a polymer to help it meet certain performance parameters, Citrine’s system can suggest changes to the material to achieve that goal. The software can be used in a similar fashion to optimize design engineering and and manufacturing systems as well. Keller says the machine learning/AI component of Citrine’s system looks for what inputs most directly affect the desired output and then factors that into future recommendations. Thus, the more inputs and outputs the software sees, the more efficient it becomes.

Citrine’s software has been used in a variety of applications including sustainability, supply chain optimization, cost-optimization, waste reduction, mechanical performance optimization, chemical performance optimization and more. Keller notes that Citrine is cloud-based, ISO 27001-certified for data security, and that all tenant/customer data is segregated and never shared with other tenants. Keller reports that Citrine’s largest customer to date is LyondellBasell (Houston, Texas, U.S.).

Thermoplastic and recyclabe panel for cabin interiors

Diab (Laholm, Sweden) received the JEC Innovation Award for the 100% Thermoplastic and Recyclable Panel for Cabin interiors. The panel is 100% recyclable, includes recycled content from production waste and is consequently 100% waste-free. Diab’s sustainable panel solution for cabin interiors takes advantage of the performance of the structural foam core Divinycell F and combines it with thermoplastic skins. Using only materials already tested and qualified by an aerospace OEM, the panel is fully compliant with all requirements within the industry, yet 100% recyclable.

Diab also created a new innovative manufacturing process that is said to save up to 20% of the cost, up to 10% of weight and offers higher mechanical and fire resistance behavior than current honeycomb core and phenolic resin/glass fiber solutions. “At the start of the project, we decided to think out of the box and push the limit of existing materials and processes,” says Aurelien Lafforgue, market segment manager Aerospace & Industry at Diab. “We wanted to simplify the manufacturing process as much as possible with a single-step process, with the panel ready to use out of the mold as the ultimate target.”

Consequently, Diab decided to avoid using an adhesive film and instead welded together skins and core to create adhesive properties much higher than the current solution with phenolic resin. The result is mechanical properties that are fully compliant with cabin interior applications. In addition, Diab decided to use a new-genera6on of coating systems developed for the cabin interior market that can effec6vely be ‘welded’ to the panel as it is molded in a single, one-step process using induction heating. This method takes minutes rather than hours, which is the case when using multiple layers.

Thermoplastics have a future in hydrogen pressure vessels

Scott Unger, managing director USA and global CTO at Toray Advanced Composites (TAC, Morgan Hill, Calif., U.S.), sat down with CW at JEC and discussed a topic that is just now getting some attention in the industry: use of thermoplastic composites in hydrogen storage applications. Unger says TAC is seeing interest in the use of thermoplastics in this market, and the reasons, as usual, revolve around sustainability, energy use, durability, long life cycle and good stress capability through pressure cycles. Thermoplastics, he says, can be used in gas or liquid vessels, but that LMPAEK could be suited for liquid storage, which requires cryo temperatures. TAC is working with partners in Europe to evaluate materials and manufacturing methods, including winding with in-situ consolidation. The goal of the cooperation is to develop technology and ultimately a demonstrator thermoplastic hydrogen tank.

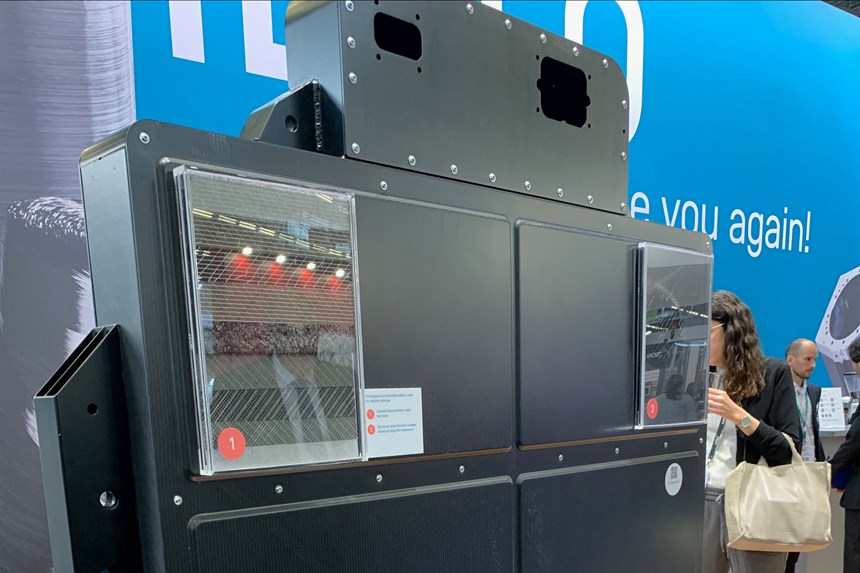

Affordable AFP

AccudyneSystems Inc. (Newark, Del., U.S. and Isle of Wight, U.K.) introduced at JEC its new Affordable Fibre Placement system, an automated fiber placement (AFP) machine that is targeted toward, and designed to meet the needs of, research labs and SMEs that are looking for budget-friendly AFP capability. The Affordable Fibre Placement system, priced at just £250,000 ($325,780), offers single-tow AFP capability in tow widths of 0.25, 0.50 or 1.0 inch, with quick and easy changeover. The placement head, mounted on the end of a KUKA (Augsburg, Germany) six-axis robot, accepts 3-inch ID standard bobbins or 12-inch OD tape cassettes, and offers infrared (IR) tow-heating with temperature feedback. Other features include pneumatic temperature control, head cooling, a modular head for easy removal and a laydown rate of up to 30 meters/minute. It comes with a Siemens HMI and PLC control system and uses CGTech (Irvine, Calif., U.S.) offline programming software. Options include a robot linear rail to expand the working envelope, headstock/sliding tailstock rotator, heated plate tooling, laser profile inspection sensor and auto-head changeover.

Multi-axial, wide thermoplastic tapes

CW ended its JEC experience in the stand of Web Industries (Marlborough, Mass., U.S.), learning about the company’s new 50-inch wide multiaxial thermoplastic tapes. Jim Powers, global thermoplastic market development manager at Web, says the tapes are offered with any of a variety of thermoplastic polymers and provided in stacks of ±45°/90°. They are seam-welded along their edges and offered in rolls up to 1,500 feel long. Powers says Web is targeting with this material continuous compression molding (CCM) equipment users and thermal forming fabricators of blanks. Powers also notes that the tapes can be custom-cut at progressively wider widths to accommodate drape over plies beneath them. Further, Web will cut and box segments per customer request and provide slitting as needed.

Related Content

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More