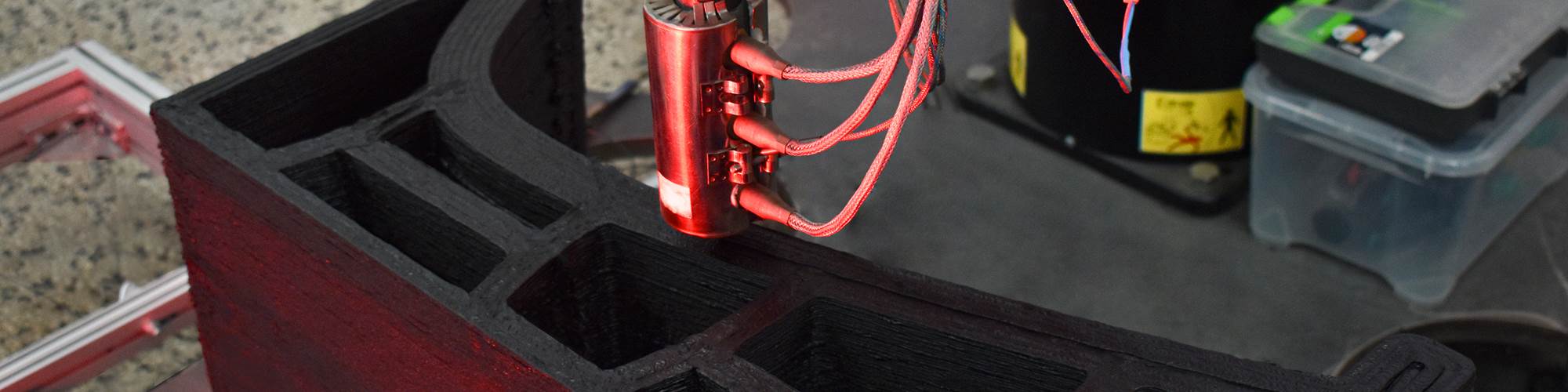

The Caracol process includes a large-scale, robot-mounted, extrusion-based 3D printer compatible with a variety of materials including up to 40% fiber-filled polymers. Photo credit, all images: Caracol

Caracol (Lomazzo, Italy) is a startup large-scale additive manufacturing (AM) specialist founded in 2017 with the goal of scaling up 3D printing for high-performance industrial applications. “Our mission is to work on increasingly extreme and advanced applications, in advanced sectors such as aerospace and automotive. We believe that large scale is the key to push additive manufacturing as a technology, way beyond what is possible today,” explains Violetta Nespolo, chief marketing and strategy officer at Caracol.

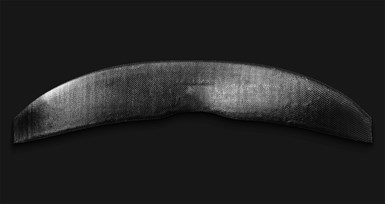

One focus area for Caracol is composite aerospace tooling. This large-scale tooling jig, used to manufacture belly fairing panels of an aircraft, measured 84.8 cm wide x 125 cm long x 37.5 cm high, printed in one piece from carbon fiber/PA.

She adds, “We started by working with existing printers, and seeing what we could do to expand the scale of what was possible. We found robotic arms give the maximum flexibility to print large, complex parts.”

After its initial research phase, Caracol ultimately developed and patented an extrusion-based 3D printing system, including design and print management software, to mount on Kuka robotic arms. Currently, the system can print parts up to four meters wide — though Nespolo says it could print up to 10 meters wide with the addition of a trolley or rail system if needed.

This automotive rear wing for a luxury automotive OEM was built from carbon fiber/PA12 via a combination of a 3D-printed composite internal liner with an additional layer of carbon fiber laminated over top for increased performance. Caracol reports a weight savings of 33% compared to the previous materials and process used, overall cost savings of 50% and a reduction in production time from six weeks to five days.

The system is compatible with a range of polymers such as polyamide (PA), polyphenylene sulfide (PPS) and polypropylene (PP), unreinforced or reinforced with up to 40% carbon or glass fiber. “We’re able to use a very broad range of materials beyond traditional 3D printing filaments, including the same type of pellets used in injection molding, which allows us to use composites with a higher percentage of fiber compared to traditional 3D printing filaments,” Nespolo says.

Today, Caracol offers clients a full range of design, engineering, prototyping and short- or medium-series production runs at its Italy facility. In addition to its patented large-scale system, the company also has capabilities for printing with FDM and SLA printers of various sizes.

The founding team at Caracol, pictured left to right: Giovanni Avallone, chief design and engineering officer; Francesco De Stefano, CEO; Jacopo Gervasini, CFO; and Paolo Cassis, COO.

The company produces a variety of prototype parts for automotive and other industries, but one of its main focuses currently is large-scale aerospace tooling, Nespolo says. For example, Caracol recently built a large-scale, additively manufactured tool for airplane belly fairings panels, printed in a single piece and then CNC machined to achieve the part’s required dimensional tolerances of 0.1 miliimeters and surface roughness of 1.6 μm. Caracol’s process reduced the number of pieces from more than 30 to one, cut the production time from six weeks to five days and saved the customer 35% in overall costs. “We’re working on finding solutions that really go beyond the traditional way of doing things,” Nespolo says. “The product can be customized and produced extremely quickly and cost-effectively compared to traditional metal tooling solutions.”

Future developments include structural automotive and aerospace part production, even larger print volumes, the addition of CNC milling for integrated part finishing and compatibility with higher-performance materials such as polyetheretherketone (PEEK), polyaryletherketone (PAEK) and continuous fiber reinforcement.

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)