Articles

Greener camping: Sonic X breaks barriers

Prototype travel trailer generates excitement, leads to new commercial models.

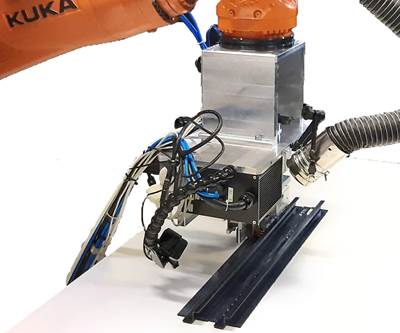

Read MoreAutomation options arise for labor-intensive composites

Typically labor-intensive fabrication processes have more automation options as new technology works in concert with operators to improve efficiency.

Read MoreThe growing role of composites in infrastructure

From bridges to rebar and pilings, composites provide installation and life cycle cost savings over steel and concrete.

Read MoreMicrofiber-infused resin enables single-step molding process

Spoke Materials’ reinforced liquid composites provide alternative fabrication methods.

Read MoreProving out LM PAEK welding for Multifunctional Fuselage Demonstrator

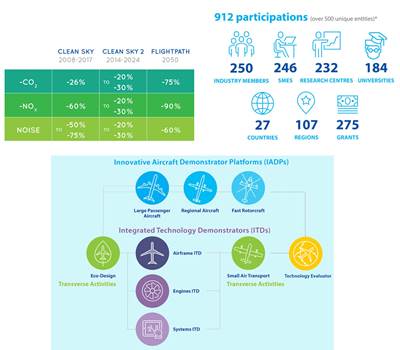

Clean Sky 2 STUNNING project will manufacture lower thermoplastic fuselage while MECATESTERS will test Toray LM PAEK in conduction and induction welding for parameters, cyclic loading, aging and environmental effects .

WatchWind energy: Gale force growth ahead

Columnist Dale Brosius addresses recent accomplishments, forecasts and recycling challenges affecting the wind energy industry — and composites use within it.

Read MoreUsing mobile susceptors to innovate thermoplastic induction welding

IS Groupe and Arkema patent ISW for high-strength UD welds, temperature control and 50% less energy.

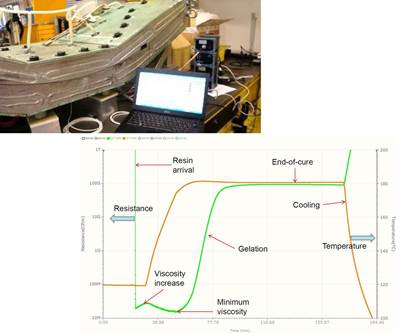

Read MoreDC dielectric sensors for industrial composites production

Synthesites in situ process monitoring enables cure decisions based on real-time Tg evaluation that can reduce cure cycles by up to 50%.

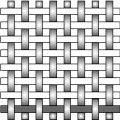

Read MoreWoven fabrics: The basics

For composite applications requiring more than one fiber orientation, woven fabrics can be useful. This primer outlines the basics of woven fabrics and different types.

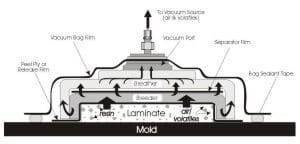

Read MoreVacuum bagging: The basics

A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to do it

Read MoreCore materials: The basics

Core materials available for composite sandwich structures range from paper, aluminum and thermoplastic honeycomb cores to foams and more.

Read MoreAramid fiber: The basics

Aramid fiber is a manmade organic polymer (an aromatic polyamide) produced by spinning a solid fiber from a liquid chemical blend. The fibers offer high strength among other properties.

Read More