Microfiber-infused resin enables single-step molding process

Spoke Materials’ reinforced liquid composites provide alternative fabrication methods.

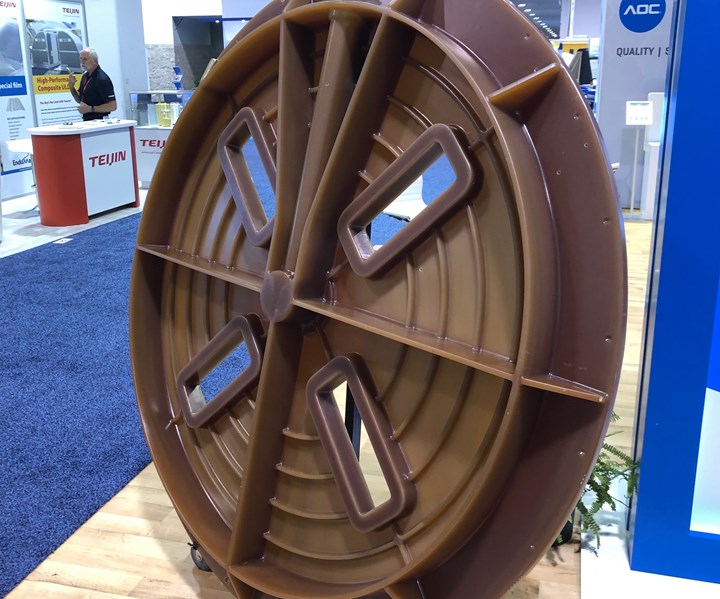

Spoke Materials’ MIR-170 reinforced liquid composite was used to manufacture a composite chemical tank base component that weighed only 180 pounds and replaced a more than 1,000-pound stainless steel part. CW photo | Scott Francis

Spoke Materials Inc. (Indianapolis, Ind., U.S.), a new resin technology company has acquired a line of molding and casting resins, structural adhesives, and pastes and putties originally developed by Mirteq Inc. (Fort Wayne, Ind., U.S.). Spoke is improving and relaunching the advanced composite material to provide alternatives to traditional methods such as RTM, hand layup and infusion that use long fibers. According to Spoke Materials CEO Joe Locke, its MIR line of products can reduce labor, raw materials cost and decrease production time for many detailed parts as the products require no additional reinforcement or expensive tooling.

Spoke’s approach uses AOC Aliancys’ (Collierville, Tenn., U.S.) vinyl ester resins, which are modified using Spoke’s Materials’ patented microfiber infusion process to develop its MIR products. Spoke’s technology first treats glass microfibers with a proprietary process and then infuses the fibers into the vinyl ester resin, which increases strength, impact and abrasion resistance, performance and durability in a single-step/single-pour molding process.

“These products are not ‘replacements’ for long fibers, but are possible alternatives for detailed applications, molded-in features or thick cross-sections where there would be a lot of manual labor or multiple materials in the fabrication process,” explains Locke. “In some cases, this alternative can replace those processes, sometimes cutting costs in half, and in some instances up to 85%.”

In most cases the single-pour approach enabled by MIR products also allows expensive tooling to be replaced by molds made of polyurethane or fiberglass tooling board, offering further cost savings. In addition, the products cure at room temperature, can be machined or milled, and are chemical- and corrosion-resistant.

One example of Spoke’s technology is a composite chemical tank base created to replace a stainless steel part that weighs more than 1,000 pounds. According to Locke, the new MIR-based part weighs only 180 pounds — 82% lighter than the original — and reduces the production time from 4-5 days to just hours. In addition, the composite version is corrosion- and chemical-resistant.

The tank base was fabricated using Spoke Materials’ MIR-170, a material specifically designed for the molding of thick parts and cross-sectional applications. The low-exotherm product allows fabricators to develop complex, detailed parts up to 3 inches thick with a decreased risk of internal cracking.

“A lot of times in those thick cross-sections you’ll get cracking and crazing, or it just doesn’t cure properly,” says Locke. “MIR-170 utilizes Spoke’s ControlCure technology allowing the part to cure evenly.”

The original stainless steel part was not only costly to manufacture, but it was also costly to ship and required heavy machinery to put in place and maintain. The composite version can be installed by one or two workers. In addition, it costs 90% less to fabricate.

According to Locke, the tank component is an example of how Spoke’s technology might enable new applications. For a customer accustomed to building chemical tank parts out of steel, the composite solution opens a new market. In the architectural sector, the material is proving to be a highly effective solution for restoring decaying stone features; such refurbishment, using traditional methods, can take weeks and cause construction delays and higher costs. With Spoke’s solution, the old part can be removed and reassembled to cast a new mold and pour using the MIR material.

While MIR materials aren’t a one-size-fits-all solution, the technology can be a cost- and time-saver in a number of applications. According to Locke, the key to using Spoke Materials’ products lies in understanding the material-application match. “We always try to get into the front end of the application before a customer starts building molds,” says Locke. “It’s important to understand what it works for and make that change up front.”

Related Content

ZEBRA project demonstrates closed-loop wind recycling system

Consortium partners have proven the complete recycling of thermoplastic wind turbines via two manufactured wind blades, featuring reduced operating cost, CO2 emissions.

Read MoreComposite wrap system combats corrosion in industrial tank repair

A fiberglass and carbon fiber composite wrap system enabled an Australian nickel mine to quickly repair a stainless steel ammonium sulphate feed tank and protect against future corrosion.

Read MoreAutomotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read MoreAl Seer Marine, Abu Dhabi Maritime unveil world’s largest 3D-printed boat

Holding the new Guinness World Record at 11.98 meters, the 3D-printed composite water taxi used a CEAD Flexbot to print two hulls in less than 12 days.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More