Luxury travel by airship returns

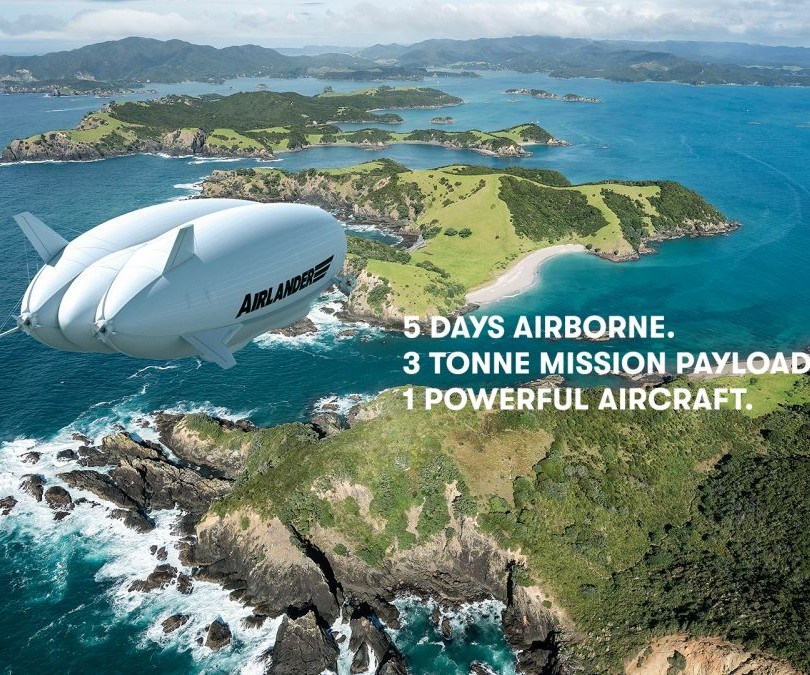

A look at composites on the Airlander 10 hybrid aircraft by Hybrid Air Vehicles, a helium-filled airship. HAV made a splash at Farnborough this year by announcing luxury tourist travel.

CW continues to cover the Airlander 10 hybrid aircraft by Hybrid Air Vehicles (HAV, Shortstown, Bedford, UK), a helium-filled airship. Originally known as the HAV-304, developed as part of program involving Northrop Grumman (Falls Church, VA, US), the airship was considered by the US Army for the US Long Endurance Multi-Intelligence Vehicle (LEMV) project, intended to support ground troops, conduct surveillance and carry military cargo. The LEMV program was cancelled in 2013, and HAV brought the concept back home, rebuilt the craft as the Airlander, and has since made a splash by announcing a focus on luxury tourist travel.

First, some background. Unlike a rigid airship like the legendary Zeppelin, the Airlander 10 has no internal structure; pressurized helium inside the vast skin allows the skin to maintain its shape and support the payload modules attached to it (more on those below). It’s called a hybrid air vehicle, says the company, because it flies thanks to a combination of both buoyant lift (due to the lighter-than-air helium) and aerodynamic lift (from air flow over the lobed, elliptical envelope shape). The buoyant lift contributes about 60% of the lift, and the aerodynamics, about 40%. Four diesel engines driving ducted propellers contribute thrust, primarily for takeoff and landings. According to the company, the Airlander 10 can stay aloft for 3 to 4 days with passengers aboard and has a cruise speed of 105 knots (or 120 mph).

The 119m-long hull skin reportedly is made from a combination of materials, including a woven liquid crystal polymer fiber from Vectran (Kuraray, Tokyo, Japan), woven aramid fiber, polyvinyl fluoride film (PVF) known as Tedlar (DuPont, Wilmington, DE, US), and Mylar polyethylene terephthalate (PET) film from DuPont Teijin films (Luxembourg) combined with polyurethane film to create a gas barrier. According to a May 2015 article about the Airlander in Aviation Week & Space Technology magazine, authored by Guy Norris, the huge hull is divided via diaphragms into six compartments, which can be sealed off in the event of an emergency; further, these compartments are fitted with ballonets (or balloons within a balloon). The ballonets can be filled with air to decrease the relative volume of the helium and make the airship heavier. Valves and plumbing allow the air to be released as needed to improve lift.

Composites come into the picture in the payload modules, which are attached to the bottom of the hull, between the two hull lobes, reportedly using cables that attach to the rigid skin. HAV’s technical data sheet says that the maximum payload capacity is 60,000 kg. HAV has worked with Forward Composites (Huntingdon, UK), a company based in Formula 1 and previously known as Lola Composites, on the composite designs. The carbon fiber composite elements help minimize the weight of attached modules, which are interchangeable depending on mission.

On July 16, at the recent Farnborough International Airshow, Hybrid Air Vehicles Limited together with Design Q (Redditch, UK) unveiled, with the slogan Rethink the Skies, a new Airlander 10 passenger cabin to showcase what’s possible in luxury expeditionary tourism. The passenger area will include private en-suite bedrooms and horizon-to-horizon views in the aircraft’s extensive Infinity Lounge, for up to 19 passengers plus crew, for 3 days. The Altitude Bar will offer drinks with the ultimate view, with floor to ceiling windows and a lounge with a glass floor.

Stephen McGlennan, HAV’s CEO, says that Airlander 10 is changing the way we think about air travel: "Airlander challenges people to rethink the skies – that’s the driving force behind everything we do," he says. "Air travel has become very much about getting from A to B as quickly as possible. What we’re offering is a way of making the journey a joy." Airlander 10 can take off and land from virtually any flat surface, eliminating the need for traditional airport infrastructure. This creates opportunities for luxury expeditions to places existing transport can’t get to and offers the ultimate in transformative, experiential travel.

The new cabin design takes full advantage of Airlander’s unique characteristics to create an environment unlike anything available in aviation today. Airlander 10’s module interior is unusually spacious; the cabin is larger than most single-aisle aircraft, such as the A320, says Design Q. This space allowed the team at Design Q to use their extensive experience in creating luxury spaces to develop unique features, over the last year.

Throughout the process, the team has been guided by engineering and regulatory demands, as well as the transition into production. HAV and Design Q will continue to work together, with further announcements expected later this year.

Related Content

3D weaving capabilities achieve complex shapes, reduce weight and cost

JEC World 2024: Bally Ribbon Mills is displaying film-infused 3D woven joints, woven thermal protection systems (TPS) and woven composite 3D structures.

Read More3D-woven composites find success in aerospace, space

CAMX 2024: Bally Ribbon Mills experts are displaying the company’s various joints, thermal protection system (TPS) technologies and other 3D woven composites for mission-critical applications.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreRead Next

Don’t call it a blimp!

The builders of this variable-buoyancy craft count on carbon fiber/epoxy trusswork to enable a new era of air transport.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More