Machine vision: Rapid error detection

Aerospace-aimed ply placement technology evolves into process management and near-real time inspection system for production laminated composite parts.

An aerospace technology that combines a camera, a laser-projection system, and special software provides inline inspection and error detection in the layup of laminate composite parts. Offered by Aligned Vision (formerly Assembly Guidance Systems Inc., Chelmsford, MA, US), it is already in use at several aerospace customers. The company hopes that, as the automotive industry ramps up composites production capacity, it also will implement automatic composites inspection at a point where error detection and defect correction are least expensive.

Hide n’ seek

The current technology evolved out of Aligned Vision’s work developing laser-templating systems, which are used for laminate composite kit cutting, layup and inspection. In the 1990s, the company was working for the US Air Force at Wright-Patterson Air Force Base’s Materials Directorate, when someone asked the team if its system’s laser and optical-aiming system (mirrors that aim a dot of laser light) could do more than project a pattern onto a part. Aligned Vision subsequently placed a camera in the optical aiming path of its LASERGUIDE projector to verify and document that design features, such as the edges of plies, were present. In so doing, the company turned a standard laser projector into an output/input device, which it called the LASERGUIDE Process Control System. Fortunately, the optical-aiming system was already tied to and driven by computer-aided design (CAD) data.

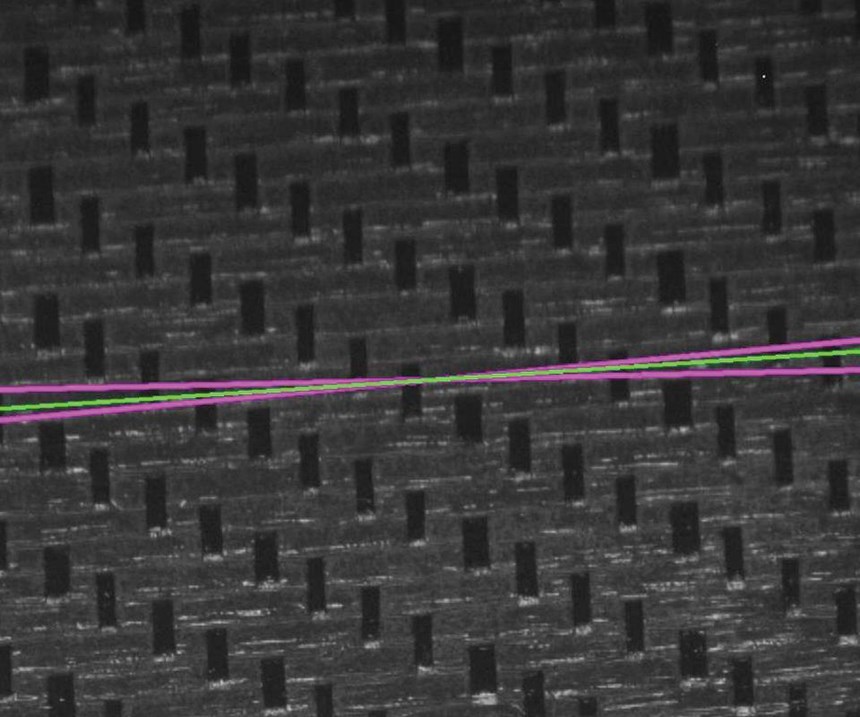

As the Aligned Vision team continued working with customers and images, they realized they could “see” much more than ply location. “With image analysis, you can see edges everywhere — thousands of strands of material,” explains Scott Blake, Aligned Vision’s founder and president. “That led us to develop automatic fiber-orientation measurement.” He notes that the system looks for optical signatures. For example, different types of fabrics are recognized by different image-analysis algorithms (i.e., a three-over-one fabric looks different than a balanced weave fabric, and a hybrid fabric of glass and carbon fiber looks different than a fabric that’s all glass or all carbon). Interestingly, the system has even been used to measure “isotropicity.” A research lab used it to verify the randomness of its spray-up work, because the flatter the system’s fiber-orientation plot, the more anisotropic is the fiber orientation.

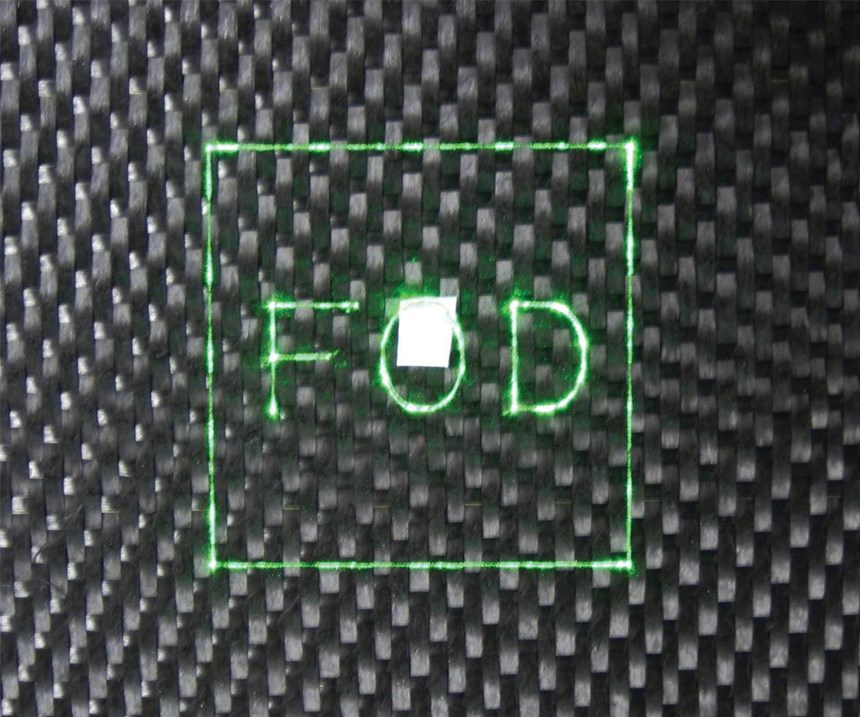

Data for analyzing the image and evaluating tolerances can be generated via commercial design tools, such as Fibersim, from Siemens PLM Software Inc. (Plano, TX, US), and CATIA Composite Workbench, from Dassault Systèmes (Velizy Villacoublay, France). Different configurations of projection and imaging can automatically detect issues, such as material shear, wrinkles and bridging, and the laser projector automatically pinpoints areas of concern, including locations of foreign objects and debris (FOD).

“FOD is ever-present,” Blake points out. “Everyone has FOD problems and it’s caused by a variety of things, ranging from static cling that causes plastic liner material to stick to plies to something falling out of someone’s pocket. I know of companies who’ve accidentally cured things like rulers, badges, coins and even a cell phone into parts. We aren’t operating in super sterile environments here.” FOD can prevent interlaminar cure and compromise part strength at its location. Automated FOD detection now enables a fast, cheap fix before the next layer’s placement, and certainly before a part is cured and found to be unacceptable — or worse, is used and fails during service.

“The approach we have and the path we’ve been driven down [by our customers] is developing a technology that lets you know that every- thing about a part is right — the right material put down in the right place in the right way — at the lowest cost and in the shortest amount of time. If something isn’t right, the system directs you to take action and make corrections before you’ve got more resources invested,” Blake adds.

The system’s projection and imaging field is a 60° cone that typically operates at a distance of 15 ft/4.6m from the part layup, thereby yielding a 15-ft2/1.4m2 envelope. For complex or large parts, multiple units can either be ganged together or mounted on a gantry and moved. Individual images of small regions within a larger, more complex field are captured in high resolution (4 megapixels) and analyzed to verify the location and presence or absence of specific characteristics (such as FOD).

The LASERVISION system is connected to a fast local-area network (LAN) and a high-end personal computer (the system becomes another node on the network). For automated composites manufacturing processes used in the aerospace industry, companies such as Electroimpact Inc. (Mukilteo, WA, US) typically purchase the system to use as a component in a large manufacturing cell. In these cases, Laservision doesn’t operate as a standalone system. Instead, it is integrated into the workcell’s control and data collection system, enabling it and the workcell’s equipment to work together, seamlessly.

Although the Laservision system has many benefits, it does have a few limitations. Because vision is a surface phenomenon, the flaw must have visible characteristics if it is to be “seen.” For example, the system may find it hard to detect very thin and transparent glass fibers or have trouble assessing if all the plies are in place in a schedule where layups are identical from one layer to the next. Unlike X-ray or ultra-sound inspection systems, it cannot detect flaws hidden deep within a part. For example, it cannot tell the operator if a core is attached to skins in a sandwich-panel composite. Another issue can be the imaging angle: the more “normal” (perpendicular to the surface plane) the angle is to the area of a part being imaged, the better; conversely, the more tangential the angle, the more challenges the system will have reading the area accurately.

And customer willingness to implement new technology also can play a role. “FOD will always be visible at some point in the process. However, a customer who’s not willing to look at the bottom of each ply? Well ....” Blake quips, “that’s where the FOD is going to be.”

The high cost of not knowing

Given the size and cost of parts in the aerospace industry, where Aligned Vision does most of its business currently, the ability to catch critical flaws when they can be most readily remedied is easily cost-justified if, Blake argues, one is looking at the right data. “Complex repairs, scrap, and lengthy material review processes have extensive costs associated with them that are not captured by traditional accounting,” he points out. “When true costs are considered, our system — which is priced between US$100,000 and US$150,000 — quickly pays for itself by preventing a small number of flaws that would otherwise result in scrap or part failure.”

The systems’ value can increase when it becomes a node on a deep-learning network. Used in combination with other process- monitoring sensors and statistical process control (SPC) tools, it can help operators characterize flaws in terms of cause and frequency, and then operators can modify the process on all machines on that network to avoid errors of the same type in the future.

Furthermore, the level of detail provided by this system’s type of automatic documentation can pay dividends at any future point in the part’s service life.

“Twenty years from now, if there’s a problem with a part, your customer will know where every splice and gap is, along with resin and other fiber characteristics in every layer of that component,” Blake posits. “Memory is [virtually] free these days. It’s much better than a distracted human inspector entering a code to indicate that a part meets spec.”

Although it is established in aerospace and defense circles, the company’s system, Blake acknowledges, is so far only used in one auto industry production environment, although Formula 1 racing teams are said to be interested in the system’s ability to verify as-built fiber orientation because it can help them optimize next-generation parts. The carmakers who have looked at the system reportedly love what it can do.

So, will the automotive industry come to value this type of near-real time error detection as well? Few would argue that for composites to have a serious impact in automotive, two things are needed: cost reduction and quality improvements. Says Blake, “For me, quality improvement means building your part and knowing that everything about it is right and at the lowest cost.

Related Content

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreAurora reveals latest SPRINT X-Plane design concept

An Aurora and Boeing team advances its high-speed, vertical lift concept to the preliminary design phase, which features three lift fans, a more refined composite exterior and an uncrewed cockpit.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)