Electroimpact Inc.

Composites Automation

4413 Chennault Beach Rd.

Mukilteo, WA 98275 US

425-348-8090

sales@electroimpact.com

electroimpact.com

About Electroimpact Inc.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Electroimpact Inc. Supplies the Following Products

- Automated fiber placement

- Automated fiber placement systems

- Automated tape laying

- Automated tape laying systems

- Carbon fiber composite

- Composite, other

- Large format

- Materials analysis

- NDI equipment, ultrasonic

- Product design

- Prototype

- Prototyping

- Surface treatment

- Tensioning equipment

- Vacuum formers

Trade Names Offered by Electroimpact Inc.

Editorial, News, and Products

-

Rocket Lab begins installation of large AFP machine for rocket production

The 99-ton AFP machine, custom-designed and built by Electroimpact, is claimed to be the largest of its kind, expecting to save around 150,000 manufacturing hours in the Neutron rocket’s production process.

-

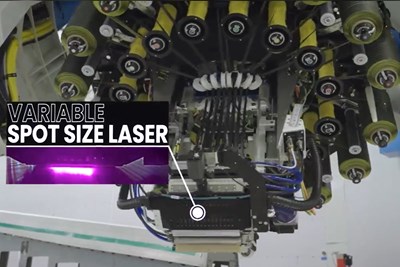

Electroimpact offers variable spot size laser AFP 4.0 technology

Patented process technology increases quality, reliability and machine utilization for composite laminate production.

-

Innovation Award finalists revealed for JEC World 2024

Returning to the international composites trade show are the Innovation Awards, representing up to 33 finalists in 11 categories that highlight composites innovation excellence and fruitful collaborations.

-

AAMMC chosen as top 20 Regional Technology Hubs

Chosen from nearly 400 applicants nationwide, the 47-member Inland Northwest consortium in Spokane-Coeur d’Alene prepares for Phase 2 in an effort to produce a testbed facility for high-rate composites manufacturing R&D.

-

Siemens and Electroimpact highlight capabilities of SCRAM continuous fiber 3D printing system

The scalable robotic additive manufacturing (SCRAM) six-axis, continuous fiber 3D printing system combines multiple processes in one cell, powered by a Siemens control platform.

-

Multi-disciplinary lab supports automated manufacturing research, prototyping

CAMX 2023: ATLAS, part of Wichita State University’s NIAR, is an integrative manufacturing environment and engineering education program for advanced manufacturing R&D with state-of-the-art machines, software and processing options.

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

-

NASA awardees to develop sustainable aviation composite tech

Fourteen Advanced Composites Consortium organizations support the evaluation and development of next-gen thermosets, resin-infused composites and thermoplastics at small scales.

-

Composites end markets: Aerospace (2023)

With COVID in the past and passengers flying again, commercial aircraft production is ramping up. The aerocomposites supply chain is busy developing new M&P for an approaching next-generation aircraft program.

-

Plant tour: National Institute for Aviation Research, Wichita, Kan., U.S.

NIAR, located at Wichita State University in the heart of the American aerospace manufacturing industry, has evolved to become a premier hub of teaching, R&D, creativity and innovation.

-

Digital design, multi-material structures enable a quieter supersonic NASA X-plane

NASA’s composites-intensive X-59 QueSST experimental aircraft is set for its first flight by the end of 2022, after nine years of design, manufacture, assembly and testing by Lockheed Martin Skunk Works.

-

Electroimpact, Toray, Janicki advance technologies for rapid, large-scale thermoplastic parts manufacture

Project combines Electroimpact high-speed AFP equipment, Janicki’s OOA heated layup tooling system and Toray Cetex TC1225 low melt PAEK UD tape for deposition rates of up to 4,000 inches/minute.

-

The evolution of additive composites

Defining additive composites manufacturing and how its merge with conventional processes is providing new solutions and a path forward.

-

Electroimpact launches plug-and-play AFP system

Automation and automated fiber and tape placement specialist Electroimpact has introduced Scorpion, a new modular plug-and-play automated fiber placement (AFP) system designed for research and laboratory applications.

-

NCC unveils AFP/ATL dual system for large, complex structures

The hybrid cell, created in partnership with Electroimpact, can be used individually or together for automated composite manufacturing at a medium- to large-scale level.

-

Victrex, Electroimpact achieve thermoset AFP speeds using thermoplastics

Using Electroimpact’s AFP technology and Victrex’s low-melt PAEK prepreg tape, the companies report laydown speeds of 4,000 inches per minute.

-

Tow steering, Part 2: The next generation

Wings on next-generation commercial aircraft will be longer, thinner, more aerodynamic and more efficient. They also are ideal candidates for the application of steered tows. One project aimed to design, fabricate and quantify a tow-steered wing skin.

-

AFP tow steering comes of age, Part 1: Current state

It used to be enough that AFP systems could precisely and quickly place and cut multiple tows to build complex aerostructures. Now, fabricators need those tows steered, and the tighter the radius, the better.

-

New 3dpbm market analysis division presents AM industry study results

Analysis of composites additive manufacturing performed by the new market analysis and consultancy group shows the market generating $10.6 billion in yearly revenues by 2030.

-

3D printing with continuous fiber: A landscape

Growth continues in suppliers, part size, production volume and markets.

-

Combining AFP with 3D printing for flexible parts production

Electroimpact creates a multifunctional manufacturing cell for complex, aero-quality continuous fiber composite parts.

-

Electroimpact’s 6-axis continuous fiber 3D printer, one part of future multi-functional manufacturing cell

The Scalable Composite Robotic Additive Manufacturing (SCRAM) system 3D prints with continuous fiber tape or filament and seamlessly swaps end effectors for large-scale pellet deposition and CNC machining.

-

Boron fiber: The original high-performance fiber

History and future developments for high-performance boron fiber.

-

Composites in the race to space

Advanced materials use in current and upcoming NASA missions.

-

National Composites Centre unveils digital composites technologies

The U.K.’s National Composites Centre unveils new composites manufacturing technologies, marking the culmination of a two-year, £36.7m digitization project.

-

Compression RTM for production of future aerostructures

Automated preforming and 5-min resin infiltration show a way forward for lower-cost CFRP primary structures.

-

A digital approach to automation

One aerostructures manufacturer’s journey from hand layup to AFP.

-

Evolving AFP for the next generation

‘Aerospace quality at automotive pace’ is the mantra of the supply chain being developed for next-generation commercial aircraft. Automation is evolving to meet the challenge.

-

CGTech joins NIAR to support ATLAS research

CGTech's AFP/ATL programming and simulation software will be used to support ATLAS aerospace composites research at the National Institute of Aviation Research.

-

Spirit AeroSystems debuts next-generation composite fuselage panel

The 18-by-12-foot (5.5-by-3.7-meter) demonstrator panel debuted at the Paris Air Show features integrated skin and stringers and offers substantial cost savings combined with strong performance attributes.

-

Automated, in-situ inspection a necessity for next-gen aerospace

Inline inspection technologies continue to evolve with the aim of providing faster and more accurate part inspection.

-

Large, high-volume, infused composite structures on the aerospace horizon

Infused carbon fiber composite structures are not new, but they have never been built at the rates anticipated for next-generation, single-aisle aircraft. It is a daunting prospect — but a feasible one.

-

Smarter, integrated data for ATL/AFP

More than helping to eliminate dry runs and costly errors, AFP/ATL software is beginning to benefit the whole product lifecycle through the interconnectedness of the digital thread.

-

Spirit AeroSystems acquires robotic Electroimpact AFP machine

The new machine, featuring an upgraded AFP head said to place material more than twice as fast as traditional machines, will be devoted to research and development.

-

Plant tour: Spirit AeroSystems, Wichita, KS

Spirit AeroSystems was an established aerospace supplier when it earned that distinction, winning the contract for the Boeing 787’s Section 41. Now its sights are set on the next generation of aircraft.

-

Improving composites processing with automated inspection

Automated, in-situ inspection bypasses the bottleneck of manual inspection.

-

Boeing begins 777X production

The Boeing company (Everett, WA, US) kicked off production of the 777X aircraft with a company ceremony on October 23. The “reveal” included a video of the composite wing spars.

-

Machine vision: Rapid error detection

Aerospace-aimed ply placement technology evolves into process management and near-real time inspection system for production laminated composite parts.

-

Cost-effective aerocomposites: Dry fiber AFP and resin infusion

Aurora Flight Sciences and NONA Composites aim to improve toughness, repeatable aerospace quality and affordability for large-scale NASA structures.

-

JEC World 2016, the full report

CompositesWorld's editors report on the technologies and products that caught our eye at JEC World 2016, in early March.

-

Automation: Robots taking off in commercial aircraft

Will this affordable and versatile class of multiaxis manufacturing hardware and software drivers enable airframers to reduce costs and speed deliveries?

-

AFP/ATL evolution: Dual-process workcells

Independent contractor and occasional CE columnist Carroll Grant draws attention to a recent phenomenon in the development of automated lamination equipment: machinery capable of operating interchangeable AFP and ATL heads.

-

Plant tour: ATK Aerospace Structures, Clearfield, Utah, U.S.

High-volume, high-precision fiber and tape placement for the aerospace industry are among many specialties for this composites manufacturing behemoth.

-

Tooling up for larger launch vehicles

NASA and Janicki Industries demonstrate composites’ cost advantage in tooling for fabrication of 10m/33 ft diameter payload fairing for next-generation launch vehicle.

-

A400M wing assembly: Challenge of integrating composites

The Atlas military transport’s decade of development has lighted the path for Airbus wing development on the A350 and future programs.

-

Composites automation: Trending smaller and robotic

Although AFP and automated tape laying (ATL) lamination technologies are widely used in the aircraft industry, market conditions in the past few years are driving some changes in composites equipment supplier product lines. Consultant Carroll Grant explains why.

-

A350 XWB update: Smart manufacturing

Spirit AeroSystems actualizes Airbus’ intelligent design for the A350’s center fuselage and front wing spar in Kinston, N.C.

-

Status update on composites automation

Consultant Carroll Grant reviews progress made in recent years toward greater variety in automated composites processing machine sizes configurations and capabilities.

-

Out-of-autoclave prepregs: Hype or revolution?

Oven-cured, vacuum-bagged prepregs show promise in production primary structures.

-

SAMPE 2010 Seattle Showcase

SAMPE’s first-ever foray into Boeing Country wrapped up with the M&P organization’s biggest draw this decade.

-

AFP/ATL design-to-manufacture: Bridging the gap

Managing production of a structure made via fiber or tape placement often requires software-aided manipulation of the subtle differences between that which is designed and that which can be manufactured.

-

ATL and AFP: Signs of evolution in machine process control

Improved machine-control software, placement accuracy and design simulation have made automated fiber placement and tape laying machines truly production-worthy. The evolution, however, still continues.

-

Aviation Outlook: Fuel pricing ignites demand for composites in commercial transports

A confluence of aircraft OEM technical innovation and economic pressures on their airline customers creates increasingly favorable market conditions for aerospace composites.