Automation, automotive, recycling and more from JEC World 2018

Mass production of automotive composites, recycling and composites in shipbuilding are just some of the themes from this year’s JEC.

Coriolis Solo

Coriolis Composites (Quéven, France) showcased their Solo machine, a compact automated fiber placement (AFP) system that lays thermoset, dry fiber or thermoplastic tape materials up to 1.5-inch wide at a rate of 1 m/s. It features fast cutting and adding fibers on-the-fly without slowing down. Coriolis also displayed a large aircraft fuselage panel and a variety of automotive parts, the latter molded from preforms made using its AFP machines. Its goals for both markets, is to enable high-rate production of parts with cycle times as low as one part every 20 seconds in automotive composites.

SOURCE: Airborne.

Airborne and Plataine partner for automated kitting

Announced during the second day of JEC World 2018, Airborne, supplier of automated and digital manufacturing solutions for composites, and Plataine, provider of Industrial IoT and AI-based optimization solutions for advanced manufacturing, formed a business partnership for automated composites kitting solutions. These will result from integrating Plataine’s Cut Plan Optimization Solution into Airborne’s automated kitting system, and will enable composite material utilization to be optimized resulting in minimized material waste and optimized factory logistics.

Plataine and Airborne’s collaboration combines Plataine’s IIoT software and Airborne‘s automated equipment, allowing manufacturers to take part-mixing to the extreme. Part-mixing is seen as a key enabler for radically lower-cost, mass-produced composites in the future, using flexible production lines that can combine small and large runs of serial production parts. Read more in my blog “Airborne, Siemens and SABIC partner to mass produce thermoplstic composites”.

SOURCE: CW

Van Wees tow to tailored preform to parts production line

The major development exhibited by Van Wees UD and Crossply Technology (Tilburg, The Netherlands) is a production line which transforms carbon tows into tailored blanks ready for press-forming. The line starts with tape-making, in which carbon tows are pulled from creels of bobbins and spread, followed by application of a thermoplastic matrix and consolidated into a thermoplastic tape. This tape is then fed into a crossply machine which feeds these and places these unidirectional tapes into oriented layers. These blanks are then die-cut into the part shape, automatically stacked and preheated, ready for thermostamping into parts. The cut plies and part shown above are for a carbon fiber/polypropylene (PP) automotive door crash beam.

Van Wees uses recycled scrap material. These “UD chips” are pressed into a semiconsolidated sheet, which is die cut and this material is added between the two multiaxial UD die-cut ply stacks. The resulting part can be seen in the far right of the left photo above. Parts with a total cycle time of 1 minute or less are reportedly possible from this production line.

|

Cetim production line for recycled composite panels

Cetim and Cetim-Cermat won a JEC World Innovation Award for its single production line combining ThermoPRIME technology for upcycling non-reinforced thermoplastic waste with Thermosaïc technology for transforming long-fiber “chips” of thermoplastic composite waste into thermoformable sheets. These sheets can then be thermoformed into new composite parts.

|

SOURCE: Voith Composites

Voith production of CFRP rear wall for Audi A8

Voith Composites (Garching bei München, Germany) also won a JEC World Innovation Award for its series production — capability is 350 parts/day - 65,000 parts/yr — of the carbon fiber/epoxy rear wall for the Audi A8. The single composite part replaces up to 5 welded aluminum parts in the current A8, cutting weight by 50% while providing 33% of the body-in white’s static torsional stiffness.

Parts production is fully automated and Industry 4.0 enabled, starting with 50K Panex PX35 carbon tow from Zoltek, which is spread, bindered, cut and placed into a highly-engineered, oriented preform. The Voith Roving Applicator (VRA) cuts the tapes to tailored lengths and places at specified angles (0-360°). The preform comprises 6 to 19 layers, with thickness in the part varying from 1.5 to 3.7 mm.

The carbon composite rear wall is molded using VORAFORCE 5300 epoxy resin from Dow and the Ultra-RTM process developed by Audi. Curing time is less than two minutes, while the molding cycle time is 5 minutes. After CNC milling, an assembly cell equipped with three robots completes all bonding and fastener installation, with the finished module shipped to the Audi A8 assembly line.

Composites in shipbuilding

SAERTEX (Saerbeck, Germany) has three finalists in the JEC Innovation Awards. One of these is the sundeck design for a 110m long river cruiser, where testing has shown that SAERTEX LEO fire-resistant composite materials are equivalent to steel as far as regulations, but superior in performance and lightweight.

Another highlight at the SAERTEX booth is the steel to fiber reinforced plastic (FRP) composite joint design and construction demonstrated in the FAUSST-Project. Developed for maritime engineering, FAUSST is a hybrid fabric featuring both metallic and non-metallic portions. Tailored knitted fabrics made out of steel and glass fiber produces a laminate that can be welded on one side. FAUSST is a ready-to-use construction element that integrates a steel sheet into the FRP part enabling easily welded yet lightweight ship structures.

Other highlights:

An automotive floor produced by the Composites Alliance of FRIMO and SCHULER at the National Composites Centre (Bristol, UK) made using carbon fiber, epoxy and high pressure resin transfer molding (HP-RTM).

TIKAT’s Smart Skin Sensor in the Startup Booster Pavilion

Exel Composites is a member of the LuxTurrim5G Ecosystem project, developing the infrastructure for the next generation in cellular communications, such as this smart 5G light pole, which combines a low-maintenance, weatherproof light support with a high-frequency radiolucent antenna.

Related Content

Aerotech Academy Puglia is inaugurated at Leonardo Aerospace site in Grottaglie, Italy

Joining the Leonardo MaTeRIA Lab and Joint Lab with Syensqo, this aerostructures training course will be 75% materials science and structural design/analysis, 25% digital transformation and AI.

Read MoreHow AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.

Read MoreDLR develops safe, flexible workspaces for robot-assisted manual draping

The EU project Drapebot works on new ways of collaborating with industrial robots for manual CFRP preforming for large aircraft structural parts.

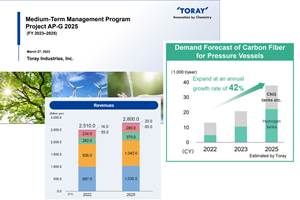

Read MoreToray announces growth, investment in carbon fiber composite materials

As part of its 2023-2025 management strategy, Toray projects 42% growth for pressure vessels, 30% growth in carbon fiber composite materials revenue and a doubling of capital investment.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)