Airborne

Laan van Ypenburg 70

The Hague, 2497 GB NL

31 70 3017400

info@airborne.com

airborne.com

About Airborne

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Airborne Supplies the Following Products

- Adhesive bonding

- Aerospace, fuselage/wing

- Aerospace, radomes

- Armor, composite

- Autoclave cure

- Automated fiber placement

- Automated fiber placement systems

- Automated tape laying

- Automotive, body panels & substructures

- Automotive, interior (seats, IPCs, floor panels, etc.)

- Carbon

- Carbon fiber composite

- Carbon/carbon composites

- Compression molding

- Consulting, business development/acquisition

- Consulting, environmental

- Consulting, materials

- Consulting, other

- Consulting, process development

- Consulting, structural design

- Continuous laminating

- Continuous laminating machines

- Cutting, finishing, and machining

- Filament winding

- Flywheels, composite

- Hand layup

- Honeycomb structures

- Marine, boat (hulls, decks, bulkheads, etc.)

- Marine, other

- Moldmaking and patternmaking

- Other composite structures

- Other preforms

- Other primary manufacturing equipment

- Preform manufacturing equipment

- Pressure vessels

- Product design

- Prototyping

- Resin transfer molding (RTM)

- Roll-wrapping machines (not tables)

- Structural reaction injection molding (SRIM)

- Tape laying

- Vacuum forming

- Vacuum-assisted resin transfer molding (VARTM)

Editorial, News, and Products

-

Design for manufacturing, assembly and automation enables complex CFRP telescope supports

Airborne delivered two mirror support structures for the FYST and SOLAT telescopes, assembling 26,300 components while maintaining near-zero CTE, strict tolerances on 6.5 × 6.5 × 1.8-meter assemblies.

-

Airborne to supply Airbus with composite components for mega-constellation satellite solar arrays

Airborne Aerospace will manufacture more than 700 composite substrate panels and yoke substrates for Airbus Sparkwing solar arrays, a critical component of MDA Space’s Aurora satellite product line.

-

Airborne completes final delivery of CFRP mirror structures for Fred Young Submillimeter Telescope

Airborne, with the help of partners, designed, manufactured and assembled two 6-meter-diameter mirror support structures for highly complex scientific telescope project.

-

Airborne to supply composites cutting/kitting equipment to Airbus Helicopters

Fully digital Kit by Light systems will enable faster, simpler and more efficient composite ply management at Airbus’ Donauwörth facility.

-

Innovation Award finalists revealed for JEC World 2024

Returning to the international composites trade show are the Innovation Awards, representing up to 33 finalists in 11 categories that highlight composites innovation excellence and fruitful collaborations.

-

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

-

Thermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

-

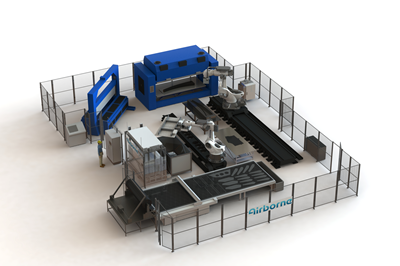

Modular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

-

Airborne to deliver automated preforming line to GKN Aerospace

Automated cell combines ply placement, preform trimming, a ply cutter and a hot drape former for 3D preform production, to be initially deployed to fulfill ASCEND project objectives.

-

Solvay, Ascendance Flight Technologies and Airborne join forces

Strategic collaboration agreement will see to the development of innovative advanced materials and aerospace technologies that will enhance the safety, efficiency and sustainability of future aircraft.

-

Third keynote is announced for annual SPE ACCE event

Gregory E. Peterson, chief engineer at aviation technology startup Airspace Experience Technologies, will be sharing his views on the trends and opportunities found in the transportation industry.

-

SPE introduces second keynote for ACCE 2023

General Motors’ Jason Coryell will be talking sustainability initiatives in automotive in his presentation, “A Role for Composites in GM’s Vision for Simulation-Driven & Sustainable Material Impact.”

-

Airbus selects Airborne to supply automated ply placement system

The pick-and-place system with software-driven automated will be the first in Airbus facilities, enabling highly efficient and flexible dry fiber preform manufacture for A350 structures.

-

Airborne delivers composite upper stage tank for EU ENVOL project

Nine-member consortium targets development of low-cost, green vertical orbital launcher with manufacture of an ultra-lightweight composite tank design in an automated manufacturing environment.

-

Airborne, Accudyne partner to provide automated composites solutions worldwide

The two companies have signed an MOA to collaborate on further development of digital automation systems for composites manufacturing in aerospace, renewable energy, future mobility and more.

-

Siemens Gamesa, Airborne develop automatic preforming robot system for offshore wind blades

Danish-funded ALMA project furthers collaboration, adds new functionality, advanced sensor systems and digital twinning for reduced man-hours, waste and cost per blade.

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

-

Limosa taps Airborne composites expertise to build LimoConnect

Airborne’s capabilities will support airframe prototyping, automated production of the Limosa LimoConnect eVTOL + eCTOL aircraft from prototype through to serial production to help meet 2028 entry-into-service goals.

-

Solvay, Airborne receive funding for composite battery enclosures

Collaboration is targeted at maximizing the energy capacity of lightweight and compact next-generation battery packs for e-mobility, while also targeting reuse of composite waste.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

-

Helicoid Industries releases three use cases of Helicoid technology

Use case applications with Helicoid technology implementation demonstrated mechanical performance improvements, such as impact resistance and strength.

-

Demonstrating composite LH2 tanks for commercial aircraft

Toray Advanced Composites and NLR discuss the Netherlands consortium and its 4-year project to build demonstrator liquid hydrogen tanks, focusing on thermoset and thermoplastic composites.

-

Siemens Gamesa, Airborne collaborate on automation of wind turbine blades

Joint efforts combine years of expertise in the manufacture of wind turbine blades, composite processing and automation to scale up operations.

-

CAMX 2022 exhibit preview: Airborne

Airborne’s Automated Ply Placement and Automated Edge Sealing technologies aim to ensure constant, repeatable and flexible production of complex composite products.

-

Global experts present latest developments at Composite Sandwich Conference in May

The CSC 2022 conference, jointly organized by Thermhex and Fraunhofer IMWS, enabled a productive exchange of information about cost-efficient composite sandwich structures and automated processing methods.

-

Cotesa GmbH selects Airborne to supply a fully automated edge sealing system

The robotic production system will automate Cotesa’s edge sealing operations for complex, 3D composite parts for the automotive and aerospace industries on-the-fly, while also maintaining accurate resin dispensing.

-

Airborne introduces Automated Ply Placement technology at JEC World 2022

Automated, accurate and fully integrated preforming process maximizes design freedom of composite laminates, expands material options.

-

Airborne automated, digital manufacturing projects backed by €16 million in EIB financing

Airborne is involved in several projects with global partners to develop and commercialize new composites automation opportunities in electric mobility, New Space, aerospace and hydrogen markets.

-

Airborne, Venturi Aviation partner up on composite structures for all-electric aircraft

Cooperation objectives to develop automated manufacturing methods that are more flexible, dynamic and scalable for the Echelon 01’s 2028 launch.

-

Airborne expands automated kitting partnerships in North America

Preferred Reselling Partners Eastman Machine and Zünd Systemtechnik leverage extensive experience in deploying cutters across diverse end markets to sell Airborne automated kitting solutions.

-

Airborne participates in three technology development projects for new mobility solutions

Airborne will develop new digital and automated composites manufacturing technologies to advance maturation of UAM, civil aviation and automotive projects.

-

Toray Advanced Composites leads research consortium for LH2 composite tank developments

Dutch industries, institutes join Toray Advanced Composites for the manufacture of a civil aviation-focused lightweight composite tank which can withstand very low temperatures.

-

In-situ composites sensors for increased production rates, smart processes and life cycle monitoring

Com&Sens FBG sensors are embedded into pressure vessels, rudders and bridges, with new edge and surface connection technology, aimed at cost-effective serial production and monitoring of composite structures.

-

SAM|XL develops closed-loop manufacturing for composites

Collaborative R&D center at TU Delft develops sensor- and robot-based automation for Composites 4.0 manufacturing, including STUNNING project for welded assembly of a thermoplastic composite fuselage demonstrator.

-

Finalists announced for the 2021 CAMX Award

The CAMX Award will recognize two innovations under its Combined Strength and Unsurpassed Innovation Award that will significantly impact composites and advanced materials.

-

CAMX 2021 exhibit preview: Airborne

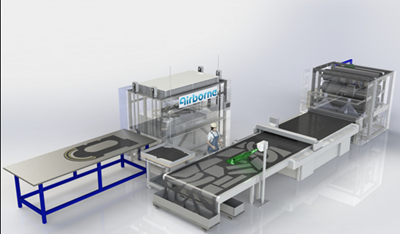

Airborne’s integrated automated kitting system can pick composites plies directly from the conveyor cutter to sort, sequence and store them in a compact and fast buffer station.

-

Airborne introduces automated pick-and-weld preforming system

The robust, flexible and versatile three-step system handles a range of dry fiber and thermoplastic composite material forms for high output, improved efficiency and reduced waste.

-

CompositeTechs to introduce Airborne portfolio to North American market

Digital composites automation equipment and services will be made available to accelerate composites adoption across a wider range of end markets.

-

Impact tests on RAMSSES ship hull demonstrator show resilience of composites

Damen Shipbuilding and project consortium partners test 6-meter-high, resin-infused composite hull section.

-

GKN Aerospace and partners launch ASCEND to accelerate high-volume composite technologies

£39.6 million ASCEND consortium to strengthen the U.K. industry’s position as the leader of next-generation sustainable aircraft and future mobility technology.

-

IIAMS wing box road map to certification

Airbus DS uses Clean Sky demonstrators as part of broad strategy to ready next-gen aircraft technology for flight.

-

Leaders in composites and continuous fiber AM to speak at MarineAM event

Inaugural two-day conference in July will feature 9T Labs, BComp, Com&Sens, Hexcel, Airborne, moi composites and others.

-

Development of dry fiber preforms and other technologies for Smart Rotors

Airborne, KVE Composites, RHIA, Royal NLR and TU Delft partner in EU project for ultra-efficient propeller/rotor blades in hybrid and electric aircraft, UAM and drones.

-

Airborne, JETCAM develop digital interface for automated kitting

Integration of Airborne’s automated kitting solution and JETCAM’s CrossTrack software provides seamless data exchange for automated kitting of composite plies.

-

Airborne launches Industrialization Partner Model

The model acts as a composite industrialization guide, enabling support from early composite production development up to technological implementation.

-

Composites 4.0: Digital transformation, adaptive production, new paradigms

An evolving landscape of automation, sensors and AI software is not an end, but a means to achieve the cost, quality, efficiency and agility required for future manufacturing.

-

Magellan Aerosystem commits to Airborne automated kitting system

Manufactured by Airborne, the solution will support fabrication of composite horizontal tail assemblies for the F-35 fighter aircraft.

-

Focus on automation leads to Severstal’s second investment in Airborne

Russian mining and steel firm Severstal’s $10 million investment makes Airborne the first-choice partner in Russia for all composite projects.

-

Severstal invests in Airborne automated composites manufacturing

Airborne will work with steel company Severstal to explore integration of metal and composites.

-

Plug-and-produce AFP system installed in one day and debuts at composites automation center

Addcomposites completes installations of its AFP-XS toolhead at KUKA Finland and SAM|XL in Netherlands.

-

Core filler for aircraft interiors promises less weight, lower costs

Von Roll’s NEXT GEN core filler is designed to maximize local stiffness and increase strength of honeycomb core in composite sandwich panels while saving weight.

-

Airborne substrate panels enable JUICE spacecraft solar array

Airborne delivers solar array substrate panels for use in the European Space Agency’s mission to explore the icy moons of Jupiter.

-

Airborne UK joins the National Composites Centre as Tier 2 member

The companies plan to work together on automation and collaborative digital projects, with the goal of reducing the cost of manufacturing composite structures at rate.

-

Into the Hyperloop

The role of composites in the fifth mode of transport.

-

Airborne, NCC to develop AFP data warehouse architecture

Using the National Composites Centre’s Automated Fiber Placement (AFP) machine, the project will develop a data warehouse to connect automation with digitalization and enable Industry 4.0.

-

Airborne launches composite printing portal

The first application of the portal is for thermoset laminates manufactured in prepreg material by Airborne’s Automated Laminating Cell (ALC) technology.

-

Increasing access to AFP

Addcomposites is democratizing composites manufacturing by leasing a low-cost toolhead that turns any robot into an automated fiber placement machine.

-

High-speed, high-rate thermoplastic composites manufacturing

A novel process from SABIC and Airborne promises high-speed, high-rate production of thermoplastic composite laminates for mainstream manufacturing and a variety of applications.

-

Evolving into continuous fiber reinforcements

SABIC expanded its materials offerings in short-fiber injection and long-fiber thermoplastic (LFT) materials to include continuous-fiber thermoplastic tapes.

-

CAMX 2019 exhibit preview: Airborne

A new online digital portal for composites laminates will be introduced by Airborne at CAMX.

-

Airborne Oil & Gas, SÍMEROS qualify deepwater TCP Risers in Brazil

The thermoplastic composite pipe riser for deepsea oil and gas applications will be the first qualified in Brazil.

-

SABIC's innovations of scale

SABIC at JEC World 2019 offered a virtual reality-based peek at its new Digital Composites Manufacturing line — a collaboration with Airborne aimed at automated, large scale laminate production of thermoplastic composite parts.

-

Solvay and Airborne to partner on developing automated processing for composite materials

The partnership aims to identify solutions to the industrialization challenges facing the composites industry.

-

Design engineering of tailored preforms

Tailored preforming has opened new doors in composites fabrication, but designing for it requires tools that understand and work with this complex process.

-

JEC World 2019 preview: SABIC

SABIC (Pittsfield, Mass., U.S., 6/P12) is highlighting the progress of its Digital Composites Manufacturing line, an automated digital systems for rapid, large-scale laminate manufacturing, via a 360-degree virtual reality experience.

-

JEC World 2019 preview: Airborne

Airborne (The Hague, Netherlands) will showcase its Digital Client Portal at its JEC World 2019 booth, Stand R11, Hall 6.

-

Airborne develops composite structures for European small launcher program

Airborne has completed its contribution to the European Commission Horizon 2020 project called SMall Innovative Launcher for Europe (SMILE).

-

Composites Europe notes process chain cooperations are accelerating composites industry growth

Composites Europe this year highlighted the coordinated processing and production processes being developed in the marketplace.

-

GKN Fokker to implement automated kitting solution from Airborne

The automated kitting solution is said to reduce costs by saving man-hours and material scrap, and it enabling a flexible and digital workflow.

-

People on the Move: June 2018

CW’s monthly roundup of people on the move in the composites industry.

-

Airborne Oil & Gas to supply TCP for vessel-to-shore concrete operations

Thermoplastic composite pipe will be used by OSL Concrete to pump ready-mix concrete from vessel-based operations to land construction sites.

-

CW Talks: Highly automated thermoplastic laminate production

The latest episode of CW Talks: The Composites Podcast, explores the collaborative development of a new thermoplastic laminate by SABIC, Airborne and Siemens.

-

Episode 17: Gino Francato, Sabic; Arno van Mourik, Airborne; John O'Connor, Siemens

Business leaders at Sabic, Airborne and Siemens discuss a collaboration by the three companies to develop the UDMAX thermoplastic laminate manufacturing system.

-

Technology Park Ypenburg program launches

Ambition Technology Park Ypenburg to become the regional and international magnet for the high-tech materials manufacturing industry.

-

JEC World 2018: The highlights

JEC World is the composites industry’s largest trade show and did not disappoint this year.

-

Airborne to manufacture solar array panels for Galileo satellites

Airborne Aerospace has been awarded a contract to manufacture substrate panels for the solar arrays of 12 new Galileo FOC satellites.

-

Airborne announces composites manufacturing partnerships

At JEC World 2018 Airborne unveiled numerous business partnership plans for automated honeycomb potting and cutting/kitting solutions.

-

Automation, automotive, recycling and more from JEC World 2018

Mass production of automotive composites, recycling and composites in shipbuilding are just some of the themes from this year’s JEC.

-

Five highlights from JEC World 2018

It’s not Spring without a trip to Paris, France for the JEC World 2018 composites conference. It’s become a very big show, and thus, offers some big announcements and some developing trends.

-

Airborne, Siemens and SABIC partner to mass produce thermoplastic composites

Flexible, automated production lines, featuring radically low conversion costs, aimed at millions of parts/yr — CW’s interview with all three companies.

-

Airborne gains oil and gas partner

On December 4, 2017, Airborne Oil & Gas (AOG, IJmuiden, Netherlands), the leading manufacturer of thermoplastic composite pipe (TCP) for oil and gas applications, announced the latest addition to its shareholder base: Subsea 7.

-

Automated manufacturing solutions from Airborne

I had the chance recently to interview Marcus Kremers, chief technology officer of Airborne International (The Hague, Netherlands), who told me about his company’s growing smart automation initiatives for its customers.

-

Airborne introduces automated kitting solutions

At AIRTEC 2017, the aerospace supply chain trade show held October 24-26 in Munich, Germany, composites specialist Airborne (The Hague, Netherlands) presented the latest developments on its Automated Kitting Solutions.