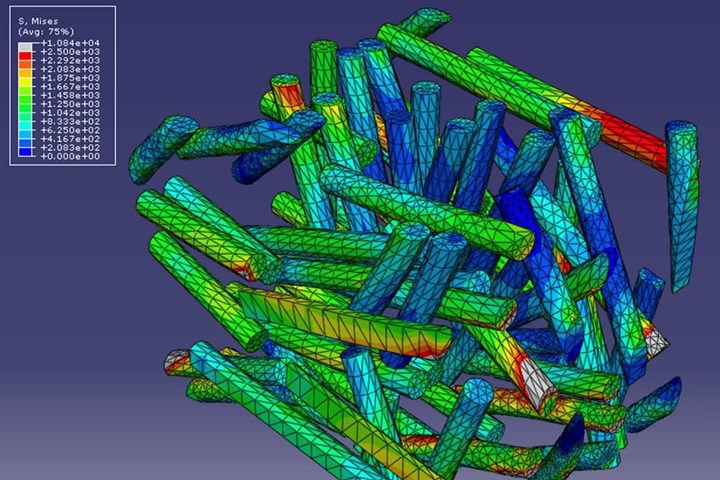

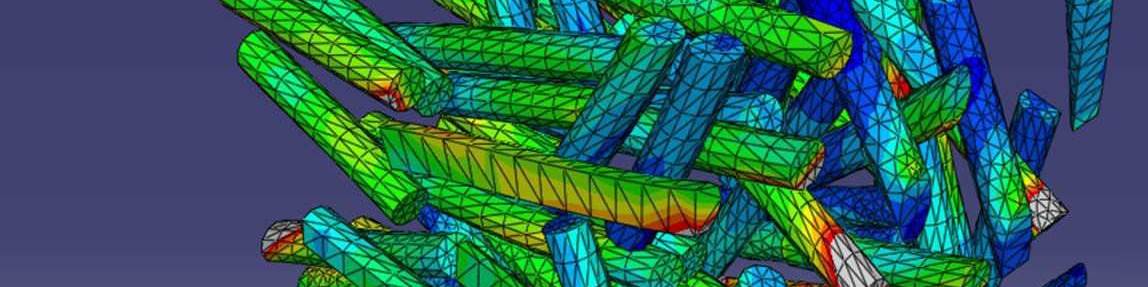

Software company e-Xstream engineering, a division of Hexagon Manufacturing Intelligence, continues to update its modeling and simulation software for improved accuracy and inclusion of a wider range of materials. Photo Credit: e-Xstream engineering

What role does digital simulation and analysis play in material qualification and part testing?

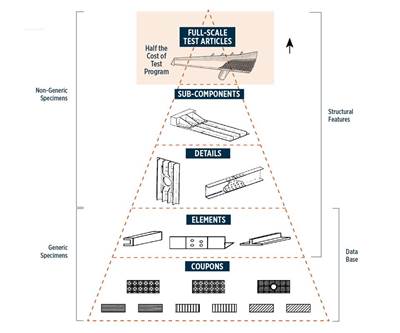

According to Dr. John Tomblin, senior VP for industry and defense programs at Wichita State University and executive director of the National Institute for Aviation Research (NIAR, Wichita, Kan., U.S.), the conversation about whether faster, potentially less expensive digital simulation tools can replace physical testing within the years-long “building block approach” (BBA) for aerospace part qualification has been going on for the past 20 years. According to Tomblin, the U.S. Federal Aviation Administration (FAA) already allows certification by analysis supported by testing (AC 20-107B, paragraph seven), so the process of analysis or simulation in the qualification process is already being used in the industry to pare down test conditions.

Today, there are a number of companies marketing virtual simulation and analysis software, such as Dassault Systèmes’ (Vélizy-Villacoublay, France) 3DEXPERIENCE, e-Xstream engineering’s (Hautcharge, Luxembourg) Digimat VA, Siemens’ (Plano, Texas, U.S.) Simcenter, Altair’s (Troy, Mich., U.S.) HyperMesh and OptiStruct, Autodesk’s (San Rafael, Calif., U.S.) MoldFlow and others.

According to Tomblin, the technology currently available suggests a hybrid digital-physical qualification process would be possible — and even beneficial — but that a fully digital qualification process is not yet feasible, at least not for products that require certification or that have human safety requirements, like aircraft or manned spacecraft.

Virtual testing “goes hand in hand with [physical] testing,” adds Roger Assaker, CEO of e-Xstream engineering. “It's not replacing testing; it allows you to do more clever testing.” He explains that digital simulation of materials and parts can be used before physical testing at each stage of the building block, to enable companies to start comparing materials and predicting failures very early in the design process, and ultimately narrowing down the number of material choices and design iterations that will need to go through physical testing.

In addition, according to Pierre-Yves Mechin, composites R&D development manager at Dassault Systèmes, the key to accelerating the role of digital simulation tools within the composites manufacturing process will be a “multi-scale” approach which includes combining digital material modeling with virtual testing through simulation. “The role of simulation and analysis is massive,” he says, and Dassault’s 3DEXPERIENCE platform is one available option.

Ideally, composite parts manufacturers can use virtual material simulation and digital analysis to create a set of virtual allowables that are created in parallel with physical testing data and also used to help inform that data (e.g., micromechanics, defects, etc.). The above image shows how virtual and physical data work together within a material data management process for aerospace OEM customers using e-Xstream engineering’s software. Photo Credit: e-Xstream engineering

From Tomblin’s perspective, the best opportunity for digital qualification is toward the end of the qualification process with full part-level testing. Up to 80% of testing for a full-composite aircraft component could be done virtually, he estimates, while 10% of a coupon-level material test could be virtual: “I think that's where the analysis and virtual engineering comes into play and combines an empirical analysis together with the new simulation tools — higher up the building blocks” at the stage of full-scale parts testing, “where you run a few physical tests and then use [digital] analysis to look at other potential test points.” Digital tools could be used to reduce the number of physical tests at this stage.

One challenge for simulation software is that mechanical properties of a composite part vary by manufacturing process.

However, though software has come a long way and can provide accurate models for many tests and materials, Assaker concedes, “We cannot do everything by simulation yet.” Companies like e-Xstream are working to make simulation software more accurate for a wider range of materials and process combinations — and, in particular, thermoplastics.

Another challenge for simulation software is that mechanical properties of a composite part can vary not just by different material combinations, but by changing the manufacturing process used to produce the part. At this point, Tomblin says, “I don't think there's an analysis technique that I've seen that will determine the differences in those different processing techniques.” Until that changes, he adds, physical testing is still needed.

Dr. R. Byron Pipes, professor of engineering at Purdue University (West Lafayette, Ind., U.S.) and executive director of Purdue’s Composites Manufacturing & Simulation Center (CMSC), believes hybrid physical/digital part qualification will become mainstream within the decade. However, he concedes that it’s “very hard to predict,” as the timing also depends on factors such as the economy, willingness within the aviation industry to adapt to the new technology and making sure that safety requirements are still being met with the same vigor.

“I think you'll soon see populations of data — virtual and real — merged and used together. This is coming, but it will take some time for the FAA and others to accommodate the change,” Pipes says. In the meantime, according to Assaker, “we have a lot of work to do to improve the acceptance and the trust of the industry with the simulation of composites, to let them know that we can deal with all the complexity that goes with it.”

Related Content

Optimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

Read MoreOptimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreTesting to support composite bolted joint analysis

An overview of ASTM Standard Guide D8509, and its coupon-level mechanical testing of design properties for analyzing composite bolted joints.

Read MoreRead Next

The path toward certification by simulation, Part 1: Verification & validation and uncertainty quantification

The movement to cut time and cost of airframe certification is gaining momentum. What are V&V and UQ and how might they support more reliable composites simulation?

Read MoreAccelerating the certification process for aerospace composites

Columnist Byron Pipes foresees the certification of simulation software in place of physical testing.

Read MoreAccelerating materials insertion: Where do virtual allowables fit?

In the quest to reduce the time and cost for aerocomposite design allowables development, will conventional physical testing and virtual testing go head-to-head or work side-by-side?

Read More

.jpg;width=70;height=70;mode=crop)