Optimizing composite aerostructures production

Israel Aerospace Industries ramps production while reducing costs and improving quality thanks to integrated optimization software.

Israel Aerospace Industries (IAI, Tel Aviv, Israel) is a globally recognized military and commercial aerospace and defense company, simultaneously a Tier 2 supplier (e.g., to Alenia, for the Boeing 787 program) and Tier 1 supplier (e.g., to OEMs like Lockheed Martin, Boeing and Gulfstream). IAI’s Commercial Aircraft Aero Assemblies division currently produces a variety of carbon and glass fiber prepreg aerostructures, including various parts that are assembled into the 787 Dreamliner.

Two years ago, as IAI looked toward Boeing’s planned production ramp to ten 787 aircraft per month, it knew controlling cost while increasing output would be an issue. The company was also committed to financial performance during an economic downturn and increasing its competitive offering in the global aerostructures market. “We looked everywhere for how to cut costs and then we saw our waste and raw materials,” recalls Avishay Hod, composite deputy director for IAI-Commercial Aircraft, Group Aero-Assemblies Division. “We buy very expensive raw materials and then cut these to form composite aircraft structures, so there is a lot of waste.”

IAI was aware of Plataine Technologies’ (Waltham, MA, US and Tel Aviv, Israel) composite cut-planning optimization software (see “Automated cutting accelerates” under "Editor's Picks"). But IAI was seeking more than just optimized nesting. Plataine suggested its Total Production Optimization (TPO) software, and the two companies began working on an implementation that would, by early 2014, cut raw material consumption by 5% and automate daily production plans for materials and cutting, greatly reducing manual tasks and improving materials utilization. This automation has freed up resources and reduced the risk of errors, which in turn has improved quality control.

Daily work plan in one click

On any given day, IAI Aero Assemblies is making multiple parts, requiring dozens of nests for its CNC cutting machines to process a wide inventory of materials. “Mostly we are cutting glass and carbon fiber prepregs,” says Hod, “but each part can use three or four different types.” While this is not uncommon for aerostructure producers, IAI’s combination of high-quality technical output with low overhead is less so. Its challenge was how to maintain this low overhead while almost doubling 787 structures output without affecting quality or production for other aircraft platforms.

Like most other aerospace manufacturers, IAI already had manufacturing resource planning (MRP) software and computer aided design (CAD)/engineering programs like CATIA (Dassault Systèmes, Velizy-Villacoublay, France). “But there was nothing that bridged the gap between these systems,” notes Plataine president Avner Ben-Bassat. He gives an example, “MRP would output the production schedule and materials inventory for each day, but the production design — i.e., what materials, shapes, tools, autoclaves and ovens were needed — was detailed in the engineering platform.” Thus, many manual operations were still required. Hod adds, “Production engineers would take the MRP print out and then go to the engineering office to pull each part’s nest from a library.” Ben-Bassat describes this library as static vs. dynamic, “There is typically one nest per kit and one or more kits per aerostructure.” Thus, the production engineer would pull each of the nests required for the parts to be made that day and send those to the CNC machining centers to be cut. “So these operations were tied to inventory and production schedule, but they were not integrated or optimized.”

“What is good with TPO is that the daily work plan is now generated from the MRP through TPO with one click,” says Hod. TPO develops the plan, produces the optimized nest, chooses the materials and provides the optimized nest files for the operator. “All of the tracking the operator used to do is now done in a few minutes,” Hod explains. “The operator’s tasks are now reduced to getting the rolls of materials and starting the cutting machine. This reduces manual labor but also opportunities for error. It increases our efficiency and our process control, which improves quality.”

Reduced waste, improved efficiency

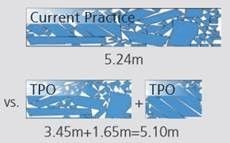

When asked about the 5% savings in raw materials, Hod admits this does not sound like much, “but when you use hundreds of yards per day of hundreds of raw materials, it adds up.” He also notes that in aerospace the typical efficiency in cutting raw materials is usually only 65-70% — i.e., 30% is waste. “So being able to reduce this also adds to the bottom line,” Hod relates.

IAI has many rolls of materials of different lengths in cold storage. “Before, we didn’t know when to best use the remnants,” says Hod. “Would we have enough to make all of the parts for that run or that day?” Now TPO does all of that analysis. “Before, looking at which rolls were closest to their expiration date and out-time limits was all done manually,” says Hod. Now it is automated through the software (see Fig. 1). “So I am gaining material that I previously did not use but I am also freeing up operator and engineering resources.”

This last point also has an impact. Hod explains, “When you have to increase your production rate, you have to spend more operator and engineering time because you are increasing the time machines are in use and the coordination of materials into products. But if you don’t double your operator and engineering hours because of something like TPO, then this allows you to increase your production rate without increasing your overhead.”

He notes one additional value due to TPO’s integration in both the inventory and MRP systems: “I can make better decisions about how much materials to buy and when. This sometimes saves more money than the 5% raw materials reduction.”

Stepwise enterprise implementation

IAI fully understood that integrating TPO into their production would require training. Ben-Bassat notes the process was made easier because “continuous improvement is in IAI’s DNA, so there was no challenge in getting everyone’s buy-in.” That said, Plataine’s experienced integration team still had to answer a lot of questions and make sure IAI’s needs would be met. “We had to make a lot of adjustments,” says Ben-Bassat. “We then began testing the configuration.” The team started with one nest on one product and performed validation tests to make sure IAI’s team got the results it wanted. “Every day we would add more products, but we kept to static nests until week two.” Plataine then began combining nests and adding products and functions until TPO was fully implemented across all parts in production. “It’s no different from any enterprise level software implementation,” says Ben-Bassat, “you don’t want to just flip the switch overnight. It took three to four months in all.”

Staying competitive

When asked if IAI has incorporated the RFID tracking available with TPO, Hod responds not now but it might do so in the future. “We are always looking to improve,” he observes, explaining that all suppliers in the commercial aircraft industry are under pressure to reduce the price of their products. “Although the parts are very expensive, we are always looking at how to do this to meet our customers’ needs,” says Hod. “We must remain competitive.”

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreRead Next

Automated cutting accelerates

Software/hardware advances and peripheral equipment make flatbed cutters essential to automated production scenarios.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)