Automated cutting accelerates

Software/hardware advances and peripheral equipment make flatbed cutters essential to automated production scenarios.

Share

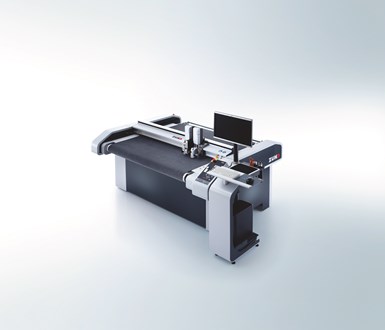

Automated conveyorized cutting tables come in all sizes, from very long to (as shown here) short, such as this one, built by Zund (Alstatten, Switzerland). Source | Zünd

As composites molders prepare to take their place in the “part per minute” automotive industry and other fast-paced industrial sectors, automation is the key weapon, and production bottlenecks are the enemy. Among the latter, one of the most troublesome is the time-, labor- and waste-intensive process of cutting and kitting reinforcement materials.

“Compared to 10 years ago, today, there are more composites production facilities, more industrial parts being produced and tighter part tolerances and specifications,” says Elizabeth McGruder, marketing manager at Eastman Machine Co. (Buffalo, N.Y.), one of more than a dozen machinery suppliers that have offered automated flatbed cutting systems to composite manufacturers for decades. “Manual cutting,” she contends, “is no longer viable.” See a video of Eastman’s feeding system.

Although a longer cutting bed can keep materials flat for pickup, a short bed like this one on a Zünd machine can be equipped with a “cradle” or basket to catch cut materials as they come off the end of the table. Source | Zünd

The good news, says Jonathan Palmer, the chief technology officer at Autometrix Inc. (Grass Valley, Calif.), is that automated cutting — in a part-per-minute or a part-per-day scenario — need not be prohibitively expensive. One recent aerospace customer, he contends, “recouped their investment in less than 12 months, based on time and labor savings, and employee satisfaction has improved, since hand-cutting has been eliminated — what used to take hours now takes minutes,” he notes.

Nesting and cutting software improve speed and utilization

Although production speed is critical, an overriding concern is the high cost of composite materials, particularly carbon fabrics and prepregs. Part cost in manufacturing is directly related to material waste and cut-ply identification and organization. Two of the greatest tools that cutting systems suppliers bring to the task, therefore, are nesting and kitting programs resident in the software that drives the cutters. “We look at the need behind the customer’s need, and solve business and process problems,” says Paul Epperson, VP of manufacturing sales at Lectra (Smyrna, Ga.). See a video of Lectra's automotive leather cutting machine.

Nesting software automatically arranges part shapes over the material expanse in a way that minimizes waste, a complex task that, manually done, could consume days. “Automated nesting software enables manufacturers to combine several jobs and nest parts using multiple algorithms to find the highest material utilization, while still controlling ply placement within the nest to ensure accurate fiber orientation and integrity,” explains Gerber Technology (Tolland, Conn.) director of industrial product management Tom Gordon. Gerber’s ComposiNest software enables a customer to nest multiple jobs from the same material, providing a greater choice of parts to nest and, thus, a greater opportunity to compact pieces more tightly together. “Field tests have shown up to 4 percent savings in composite material use with automated nesting compared to manual nesting,” he reports. The software enables nest generation and cutting 24/7, to meet peak production needs.

American GFM (AGFM, Chesapeake, Va., the U.S. marketing arm of GFM GmbH, Steyr, Austria), which manufactures several types of composites-related machine tools including this model US-15 flatbed ultrasonic ply cutter, with a 32-ft/9.75m cutting length. Source | AGFM

Kitting functions automatically label, assign layup order and assign other identifiers to cut pieces. To identify cut parts and accelerate the kitting process, Gerber’s InfoMark cut-part identification system, for example, prints and applies paper labels, or customers can specify InfoJet, which automatically prints alphanumeric text on cut materials, using a variety of inks (including Boeing-spec ink).

Lectra’s Diamino nesting software, developed in-house (Version 6 is the current iteration), is a key part of Lectra’s composites offering, and Epperson says it is constantly revised and upgraded to achieve greater efficiency. “Even small upgrades in the nesting program can significantly reduce costly material consumption, and positively impact the bottom line,” Epperson claims.

Epperson notes that with today’s conveyorized cutting beds, nesting programs have become more efficient, because the available nest length is as long as the material roll, a huge benefit because end loss and process setup time are greatly reduced. He cites the case of GKN Aerospace (Cowes, Isle of Wight, U.K.), where to keep pace with lean manufacturing goals, manual and ultrasonic cutting operations were replaced with multiple Lectra tables for single-ply nesting, cutting and marking. The move significantly reduced material waste, according to Peter Steen, GKN’s value stream manager, composite logistics.

David Cook, operations manager of Pathfinder ACT Pty. Ltd/DC Services (Hickory, N.C.), the U.S. arm of Melbourne, Australia-based Pathfinder Pty. Ltd., says nesting and kitting improvements permit customers that make very long, thin parts to cut pieces longer than the conveyorized bed from the roll in a continuous process. “The cut pieces are simply caught and folded into a ‘cradle’ device as the bed advances,” he notes. The company’s Pathworks CAD system and PathCut cutting software, developed in-house, enables manual drag-and-drop of cutting file pieces, or it can automatically select for best nest efficiency. Cook is a proponent of cutting straight from the roll, for the most efficient nests. Pathfinder’s “color bundling” feature color-codes each kit’s cut pieces on an optional offload display screen, a useful feature especially when multiple part kits are cut from multiple rolls of material.

All of the vendors interviewed for this article offer ways to identify cut parts and accelerate kitting. Gerber Technology’s (Tolland, Conn.) InfoMark cut part identification system prints and applies paper labels, or customers can specify InfoJet, which prints alphanumeric text on cut materials using a variety of inks. Source | Gerber Technology

Some customers don’t want or need a conveyorized system, but need instead a system that can cut quickly in a prototyping or production setting, often where space is limited. Autometrix, therefore, improves throughput via optimized motion control, a feature that Palmer says is especially beneficial when cutting prepregs, for which material out time is a concern. PatternSmith software, developed in-house, guides the cutting, and has a built-in interface with software from Laser Projection Technologies Inc. (LPT, Londonderry, N.H.). Customers, then, can easily integrate LPT’s projection system with the cutting process, to guide operators in cut piece pickup order, for kitting applications.

Autometrix also integrates its software with nesting software from Scapos (Scapos AG, Sankt Augustin, Germany) and Nestfab (New Basford, Nottingham, U.K.). “Our software allows importing of piece patterns from engineering CAD programs, and then offers easy-to-use tools to optimize these patterns for very smooth and fast machine cutting,” Palmer contends. At Composite Solutions (Auburn, Wash.), whose Autometrix machine cuts prepregs eight hours a day, tooling manager Dave Garrett says, “The software was easy to learn and we decided to add automatic nesting with our new machine. It was a great decision and big time saver.”

McGruder cites increased interest in Eastman’s trademarked EasiSelect software. “If you are molding multiple parts that require several different materials, it’s more efficient to cut everything you need from the first material roll, one time, then move to the second roll, and so on.” The software analyzes the parts’ data, identifies the materials they require, nests for minimum waste, then cuts all pieces that can be cut from each material roll at one time, then clearly marks the pieces to indicate which part kit they belong to, before moving to the next roll. Marking can be done via pen, ink jet, air brush or stick-on labels — functions integrated within the cutting head. “The EasiSelect software is very helpful for organizing a company’s bill of goods, especially for complex, multicomponent parts,” she adds.

AXYZ Automation’s (Albrighton, Wolverhampton, U.K.) PanelBuilder software system contains advanced nesting and optimization features that can operate in fully automated or semi-automated mode to reduce waste when cutting pre-formed sheets of material, says Robert Marshall, VP of market development. The software’s material library can be used for stock control, ensuring that there is sufficient material available for scheduled jobs. PanelBuilder includes barcode labeling for identifying parts in large kits, and, says Marshall, the barcode feature also can be used to start the correct cutting program, automatically.

Automated feeding of material onto the cutting table can improve production efficiency, with devices such as this double power cradle from Eastman Machine Co. (Buffalo, N.Y.). Eliminating manual feeding improves cutting speed and worker ergonomics. Source | Eastman Machine

Axel Hofmann, the executive VP responsible for U.S. sales of Gunnar USA Inc. (Rebstein, Switzerland) cutting systems, says that his customers can choose an entry-level, manual nesting application or an automated nesting software suite with a wide range of additional CAM features. “The core nesting program is developed externally by a well-known German research institute, but the front-end user interface is provided by our Gunnar workbench software partner,” adds Hofmann.

Zünd America Inc. (Franklin, Wis., and Alstatten, Switzerland) offers an interactive and multifunctional user interface, the Zünd Cut Center (ZCC), says Beatrice Drury, Zünd America’s director of marketing and communications. ZCC’s material database can track the fabricator’s stock, and its “cut queue” feature precalculates the processing time for each material and saves data on actual time expended. “ZCC recommends the best tool for the job, based on the installed cutter configuration,” adds Drury. “Depending on material and job specifications, the operator can select a higher speed for greater throughput or slower speed for better edge quality or tighter tolerances. Either way, the system helps take the guesswork out of cutting and dramatically reduces the potential for errors.”

For nesting, Zünd offers several solutions, including AutoNest software (developed by Zünd UK in St. Albans, U.K.), which imports drawings from any CAD package and, says Drury, quickly designs a tightly nested layout. A virtual machine simulator allows operators to preview how the nest will appear on the cutting bed. “The software is also compatible with other nesting programs, and is designed with ‘open’ architecture so a customer can integrate with other systems, such as a laser projector for kitting.”

American GFM (AGFM, Chesapeake, Va., part of GFM GmbH, Steyr, Austria), which manufactures several types of composites-related machine tools including ultrasonic ply cutters, has developed its NS2 Nesting system, which optimizes the cutting process in several ways, says Frank Elliott, the company’s advanced initiatives coordinator. “NS2 optimizes cutting feed rate, based on our ply cutter’s very high-speed feed system. It also is based on the optimum ‘part shape smoothing routines’ that are unique to us.” He adds that AGFM provides CNC-controlled, integrated inkjet marking or labeling, which he asserts is much faster than pen marking.

Hardware changes hastening production efficiency

Eastman, says McGruder, also sees increased demand for conveyorized table systems. “We believe it’s driven by the need to synchronize multiple continuous production machines,” she says. “The cutting table has to keep up with an automotive manufacturing cell, for example.” She reports that longer conveyorized tables are being requested more frequently by customers, as well. Rather than a standard 16- to 20-ft (5 to 6.2m) length, Eastman is now manufacturing tables that are 36 ft/11m long and longer. McGruder explains that longer tables keep prepreg materials for lengthy parts from folding or rolling, which could compromise their integrity. Greater length also enables multifunctionality: While cutting occurs on one end, manual or robotic piece pickup and kitting can occur on the other.

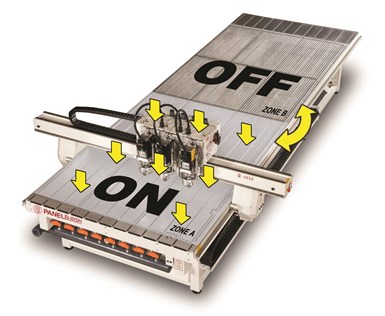

“Pendulum processing,” developed by AXYZ Automation (Albrighton, Wolverhampton, U.K.), enables continuous processing on a static table, by automated switching of vacuum zones. While cutting occurs on one half of the table under vacuum, unloading of cut parts and loading of fresh material can be easily on the other half. Source | AXYZ Automation

Marshall explains that AXYZ’s static tables can be configured with twin virtual processing areas, which operate simultaneously in “pendulum processing” modes that, in effect, “lengthen” the table. The control software automates the switching of vacuum zones, allowing the cutting of one set of part pieces on one half of the table, while the other half is unloaded, then reloaded with new material to start again. “Pendulum processing allows true continuous production,” he asserts.

Lectra offers customers a modular, add-on bed extender for conveyorized systems, says Epperson, to increase the available flat space for cut-piece pickup and kitting. Ink printers integrated into the cutting heads print part identifiers directly on prepreg materials that can’t be marked with a pen or adhesive label.

Drury says Zünd’s table extensions can double the machine length to free up space for cut piece offloading. For longer machines, half extensions are also available. On prepregs, Zünd multitool cutting heads can be equipped with an inkjet marking system from Videojet (Wood Dale, Ill.)

Gunnar’s Hofmann says, “The GUNNAR TTC119 cutting machines are manufactured to lightweight standards, and as a result have one of the smallest installation footprints.” Despite its smaller size, output is reportedly equal to larger tables thanks to system speed, and he adds, “Less space and equipment are needed for the same output, which lowers overall production costs. For example, one machine operator can manage both the cutting and the offloading, with the automatic material advance.”

Automated feeding vs. manual loading

To increase machine efficiency, cutters can be equipped with a custom-designed system that facilitates continuous cutting by automatically feeding and spreading the rolled broadgoods.

Pathfinder can pair its Easy Loading Feeding Table with its conveyorized tables. As the device feeds material into the machine, material alignment with the table edge is maintained via the system’s optical sensors.

Eastman sells several automated feeding and spreading systems, engineered and built in-house, for typical roll widths and weights. These include motor-driven roll stands, and power feed systems that can handle multiple rolls. Infrared edge control maintains precise material, and tension controls preserve fiber alignment. “We’re helping customers to address time-consuming problem areas,” McGruder notes, adding, “Automation relieves workers from having to manually load the material onto the table, for better ergonomics and higher speed.” Also available are rewinding modules on the downstream end of the table, which gather long cut strips or pieces for later laydown in the mold, typically for wind blades or other large parts.

This screen shot of Lectra’s (Smyrna, Ga.) Diamino nesting software (Version 6) shows how composite material is “nested” or grouped tightly together to avoid unnecessary waste. Color coding identifies each kit’s pieces. Source | Lectra

“We studied one customer’s operation and found that actual cutting was occurring only 38 percent of the work day, says Lectra’s Epperson. Lectra’s patented Eclipse feeding option now allows the head to continue cutting even as material is advanced onto the conveyorized cutting surface. This prevents wasted “dry haul time,” he says, and the gradual and continuous flow of cut parts also eases the off-loading task. He asserts that Eclipse alone enables a 5 percent or greater productivity increase in a production setting. Using a software feature employed in the garment industry, Lectra’s CAD system can tell the head to identify and cut the parts from parallel strips, explains Epperson, dispensed simultaneously from narrow material rolls, such as four parallel 18-inch/450-mm wide strips of prepreg.

Gerber’s single-ply material feeding device, used in conjunction with its conveyorized tables, features a synchronized cradle that accurately feeds dry composite material onto the cutting surface with little or no tension, says Gordon. A built-in infrared edge sensor ensures precise table alignment.

Assyst-Bullmer Inc. (Wakefield, U.K.) director David Bell also points out, “If prepreg pieces are cut with the release film in place, the robot must remove it before placing the piece in the mold, which really slows down the process.” The solution? The company recently added a new device to its roll feeding systems that removes the interleaved paper or polymer film — top film, bottom film or both — from prepreg material as the material is fed onto the cutter, to improve robotic pick and place.

“Large cutting machines often have a problem when it comes to holding material securely in place while being cut,” observes AXYZ’s Marshall. AXYZ’s remedy is its “auto-zone manager,” which automatically adjusts the vacuum deck configuration during cutting so that the vacuum is focused only at the area being cut. The enhancement reduces waste caused by sheet movement and requires no human intervention.

AGFM has a totally automated material dispensing system that is controlled by the machine’s CNC program, says Elliott. It can automate the change from one roll of material to a different material roll, saving considerable time.

Robotic cutting-to-molding integration

“Using robots to pick up cut pieces from a composite ply cutter and place them either into a tool or a direct press former is logical and essential where composites are required in high-volume production — the challenges are in the details,” says Assyst Bullmer’s Bell.

Although Assyst Bullmer supplies static and conveyorized cutters, for robotically assisted applications, only a conveyorized table can move the pieces forward to the robot. If a robot is to choose and place a ply accurately in a tool, it must know the exact orientation and location of the piece on the table. “If the robot’s needs control the nesting, so that the pieces come out in the order it would place them in the tool,” he points out, “nesting efficiency … is unacceptably low.” The company has developed nesting software that harmonizes the often conflicting need to simplify pick-and-place for the robot and the desire to minimize waste by nesting pieces most efficiently. Bell points out that the robot can pick up pieces individually or, better, pick up a full “window” of parts, leaving the scrap to be pushed into a container by the moving table surface.

“We can recommend an effective cutting solution that’s compatible with many different CAD, cut file formats and ERP systems, and offer standard interfaces for robotic communication on the offload side,” says Gunnar’s Hofmann. “For us, it is important to work together with our customers to analyze their specific needs. He adds that the company’s robotic interface provides a fast automatic way to offload cut parts. “But, depending on the application, our laser projection identification system is an efficient way to optimize manual offloading, as well.”

Zünd’s “open” control systems make that company’s cutting tables compatible with many other types of peripheral equipment, including robotic control systems, which facilitate their incorporation into high-rate production molding cells: “We’re not selling a canned solution,” says Drury. “We offer customized, and adaptable, solutions for many processing situations.”

AGFM actively incorporates commercial robots, as well as internally produced automated pick-and-place systems, into its machine systems, notes Elliott. “These types of application requests from customers are reviewed in detail by our technical staff to determine the best solution,” he adds.

Lectra’s Epperson, whose background includes robotic manufacturing, sees more automation on the horizon, including robotic pick and place, but points out that his customers typically add such systems after purchase of a cutting table. As regards robotic integration, Cook sees the utility, but still believes that a human operator is best: “There might be a benefit with a robot, but a human operator can inspect the cut pieces and identify potential quality issues.”

Keeping up with the press

In the end, it comes down to making molding processes more efficient to compete with lightweight metals, particularly in the automotive sector. But a production line is only as fast as its slowest link. Automated cutting plays a critical role in removing the bottlenecks that remain in the industry’s pursuit of production speed.

Related Content

Understanding vacuum bagging layers in production, repair

Recognizing the functions of each layer in a vacuum bag schedule can help users discover what vacuum bag schedules work best for their application.

Read MoreCo-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreReal-time assessment of thermoset composites curing

The combination of material state management (MSM) software and an encapsulated sample rheometer (ESR) enables real-time cure recipe management or cure model development inside the autoclave.

Read MoreBio-inspired EV underbody panel developed by TPI Composites, Helicoid Industries

Composite underbody panel for battery pack protection, made of stacked multiaxial noncrimp fabric, will serve high-volume commercial and automotive markets.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More