PCB environmental concern: Hit and miss

Efforts to eliminate substances deemed environmentally unfriendly by consumers have already had a significant impact on the printed circuit board (PCB) market.

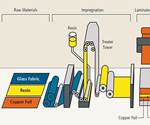

Efforts to eliminate substances deemed environmentally unfriendly by consumers have already had a significant impact on the printed circuit board (PCB) market. One result is the move to lead-free solder. Another is replacement of brominated fire retardants (BFRs). In this case, the main fire retardant used in PCBs, tetrabromobisphenol-A (TBBPA), has not been banned or deemed hazardous, but because the general public does not differentiate it from other BFRs, which are suspect, electronics OEMs have moved away from all BFRs. This case of mistaken identity is driving the trend toward “halogen-free” laminates. And this trend has, unexpectedly, opened the door for benzoxazine resins (see “BMI and benzoxazine battle for future OOA aerocomposites,” under "Editor's Picks," at top right).

The next push appears to be in recyclability. There are movements afoot to increase the ability to recycle PCBs at device end-of-life and to use more recycled content in PCB manufacturing. Although metals are relatively easy to recycle, nonmetal content in PCBs — reportedly comprising 60 to 70 percent of the PCB’s weight — offer much less value to recyclers and are much less easily recycled than metals. In fact, most nonmetal PCB waste currently is landfilled, incinerated or ground for use as filler and aggregates.

Recent studies, however, have shown that glass fiber recovered from PCB boards has sufficient properties to be effective as noise and thermal insulation. In the face of these challenges, three U.K.-based companies — National Physical Laboratory (NPL, Middlesex), In2Tec (Kettering) and Gwent Electronic Materials (Pontypool) — have developed an adhesive that allows easier separation of PCB components. As part of the U.K. government-funded ReUSE project, these companies demonstrated a 90 percent recyclable lamp inverter circuit in which the adhesive bond was able to withstand thermal cycling and hot/wet stressing, yet easily came apart after immersion in hot water.

PCB laminate performance and manufacturing requirements are very high, so biomaterials have made no real inroads. In 2004, however, work by Dr. Richard Wool, director of the Affordable Composites from Renewable Sources (ACRES) program at the University of Delaware (Newark, Del.), showed some potential. His team transformed waste feathers into compressed fiber mats. Feathers are formed from the protein keratin, which, in fiber form, is light and tough enough to withstand mechanical and thermal stresses. The mats were coated with soybean oil to achieve the desired dielectric constant.

Of the laminates tested for PCB performance, the best — 30 percent keratin by weight — reportedly met industry strength and rigidity requirements, exhibited a CTE similar to polyimide, and maintained a dielectric constant of 1.6, compared to 3.8 for silicon dioxide. However, no further progress has been reported.

“Green” trends in PCB materials will continue to be hit and miss until recyclability commands as much consumer value as performance and cost.

Related Content

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

.jpg;maxWidth=300;quality=90)