Aeroengine Composites, Part 2: CFRPs expand

Proven in fan blade/case applications, carbon fiber-reinforced polymers migrate to previously unanticipated destinations nearer the engine “hot zone.”

Since 1980, average fuel usage in commercial aircraft has plummeted by 27% for widebody aircraft and 35% in narrowbody models. Composites have played an indispensable role in that transformation. But as noted in the CW August 2015 issue’s Market Outlook: “Aeroengine Composites, Part 1: The CMC Invasion,” the Advisory Council for Aviation Research in Europe (ACARE) has called for a 75% reduction in CO2 per passenger-km, a 90% reduction in nitrous oxide (NOx) emissions and a 65% reduction in noise by the year 2050 compared to performance levels recorded in 2000 (to read Part 1, click on its title under "Editor's Picks," at top right). This is just one of many programs aimed at demonstrating cleaner, quieter and higher performing aircraft engines within the next few decades.

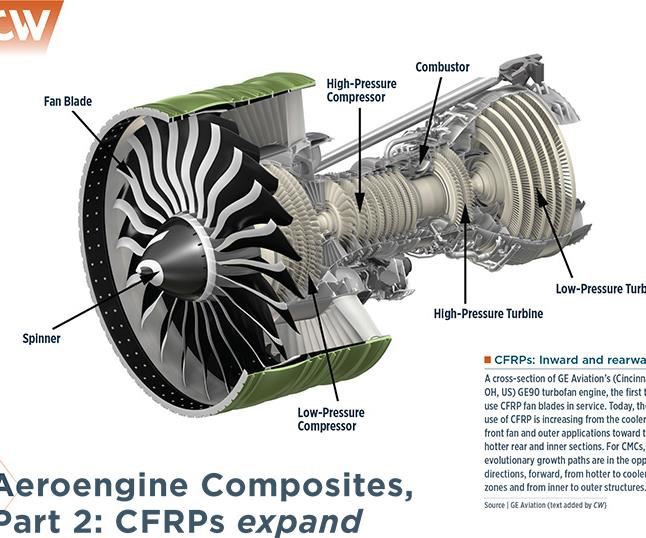

Part 1 chronicled the migration of ceramic matrix composites outward from obvious applications in the aeroengine “hot zone,” where engine components must handle high temperatures generated by combustible gases in the core at the engine’s rear. In Part 2, we see carbon fiber-reinforced polymers (CFRP) evolving inward and rearward from now familiar duty as replacements for metal in fan blade and fan case to once unlikey duty nearer the hot zone.

Evolution of CFRP in turbofans

A key driver for composites use has been the need to increase the engine bypass ratio (BPR). BPRs have increased from 5:1 in the 1970s to 10:1 for the new LEAP engine and 15:1 for the Rolls-Royce (London, UK) UltraFan, aimed for entry into service in 2025. BPRs of 50:1 or better are deemed possible by 2050 via advanced concepts, such as the open rotor (read CW contributor Chris Red’s discussion of bypass ratios, engine efficiency and the forecast for growth of composites in aircraft engines in “Composites in commercial aircraft engines: 2014-2023,” under "Editor's Picks"). Larger BPRs result in better fuel efficiency, but also increase the size and weight of the air-delivering turbofan.

For that reason, CFRPs have been used for some time in turbofan blades and protective fan cases that prevented damage elsewhere on the aircraft in case of “blade out” incidents. Rolls-Royce actually used glass fiber/epoxy in its RB108 engine compressor blades and casing, designed in the 1950s, and a carbon fiber-reinforced epoxy called Hyfil in its RB211-22B turbofan blades in the 1970s. Unfortunately, the Hyfil blades lacked sufficient bird-strike resistance and manufacturing repeatability, forcing the company to switch back to titanium before the engine’s entry into service.

GE Aviation’s (Evendale, OH, US) GE90 — which powers the Boeing 777 — was the first turbofan engine to use CFRP blades in service. According to manufacturer CFAN (San Marcos, TX, US), each blade is made from more than 1,700 pieces of hand-layed CF prepreg, autoclave-cured and precision-machined, requiring 340 hours per blade. The GE90, which entered service in 1995, also uses composites in the fan stator case, fan platforms and acoustic panels, all made at GE’s Batesville, MS, US plant.

The GEnx turbofan for Boeing 787 and 747-8 aircraft also uses CFRP blades, and extended CFRP into the front fan case, reportedly the world’s first for the latter. For the GEnx, Toray Industries Inc. (Tokyo, Japan) T700 standard-modulus fiber is braided by A&P Technology Inc. (Cincinnati, OH, US) into biaxial and triaxial (0°, ±60°) fabrics. Compared to 3,000 blades/yr reported for the GE90 in 2007, GEnx production approached 1,800 blades/yr in 2009.

Production for LEAP engines, for Boeing 737 MAX, Airbus A320neo and COMAC C919 aircraft, dwarfs both of these at 28,000 CFRP blades/yr — i.e., 50 blades/day in each of two factories: Commercy, France and Rochester, NH, US. Part of what makes this high volume possible is the switch to 3D composites using 3D woven textile preforms, produced by Albany Engineered Composites Inc. (AEC, Rochester, NH), and the use of resin transfer molding (RTM), which quickly injects epoxy resin and cures the parts in one operation (read about production of the LEAP carbon fiber fan blade and containment case in “Albany Engineered Composites: Weaving the future in 3-D,” under “Editor's Picks”). Building up and dropping off plies to tailor strength and stiffness is achieved by hand with prepreg blades, but with 3D composites, this is achieved by weaving machines, fabricating a single, near-net-shape precision preform for the part. This same technology, applied to the LEAP fan case using a 30m-long, net-shaped 3D woven preform, cuts weight 30% vs. aluminum and meets blade-out test requirements without the manufacturing, assembly and weight of a separate containment ring. Platforms between blades and spacers at the blade root also feature complex geometry, using 3D preforms and RTM.

Similar to the LEAP’s platforms, CFRP annulus fillers (Fig. 1, at left), developed and molded by FACC (Ried im Innkreis, Austria), will be used in the next generation of Rolls-Royce Trent engines, the Advance, slated to enter service by 2020. These parts cut weight by 40% vs. metal, which, when multiplied by 18 to 22 fillers per engine, reduces load on the metal fan disk, enabling the use of a lighter disk — a benefit also seen in the LEAP engine.

After 10 years of research, Rolls-Royce claims it now has a design and production system that manufactures CFRP fan blades that can compete with its previously thinner and more aerodynamically efficient hollow titanium (Ti) blades. The CTi blade — CTi refers to its carbon composite structure and Ti leading edge, reminiscent of the LEAP engine’s blade — has been tested on a Trent 1000 advanced lightweight, low-pressure system (ALPS) demonstrator engine with a 2.8m-diameter fan that uses 18 blades, reduced from 20. According to Rolls-Royce chief engineer for future programs and technology Alan Newby, the new blade design combines CFRP’s low mass with Ti blade aerodynamics via “3D layup techniques” that produce sufficient strength to reduce the blade thickness, driven primarily by bird-strike requirements.

CTi blades are made using Hexcel (Stamford, CT, US) HexPly M91 high-toughness, CF/epoxy prepreg, supplied as slit tape for robot-controlled automated layup of the complex aerodynamic shape, which is then autoclave-cured. Hexcel also is supplying intermediate-modulus CF materials and out-of-autoclave (OOA) resin for the CTi fan case.

Leehamnews.com reported in 2014 that Rolls-Royce had developed a 3D woven carbon fiber production system using resin infusion as part of its CTAL joint venture with GKN Aerospace. CTAL was established in 2008 to pioneer manufacturing processes for composite fan blades and fan cases. GKN sold its stake to Rolls-Royce in 2012. Rolls-Royce will move the Isle of Wight, UK, composites development center to its Bristol, UK, facility in 2017. Described as a “pre-production” facility, it will abut Rolls-Royce’s new-build factory to produce CFRP electrical harness rafts. The composite rafts simplify installation and maintenance of the engine’s pipes and cables (often called engine dressing), which are attached to the turbofan casing.

The Advance engine’s CFRP blades, case and rafts are said to save up to 680 kg and contribute a 20% improvement in fuel efficiency and an equivalent reduction in carbon emissions vs. early Trent engines. The follow-on UltraFan, targeting service in 2025, also will use composites to achieve a projected 25% boost in efficiency/emissions reduction. These represent a respective 6% and 10% advancement over the Trent XWB, which is currently an engine option for the Airbus A350 XWB and does not use CFRP fan blades or rafts. The Trent XWB does use a rear CFRP fan case (i.e., at the rear/exit of the fan section), fan track liners, bifurcation linings and anti-fluid panels, all manufactured by FACC, which will ramp deliveries to four shipsets per week at rate production in 2017.

FACC also builds the CFRP outer bypass ducts for Rolls-Royce (see Fig. 2, at left). These lightweight, sound-absorbing structures channel the outer bypass air past the hot engine core. FACC has produced more than 1,000 of these for Rolls’ BR700 family of regional and corporate jet engines since 2001 and also worked with Pratt & Whitney to develop its first composite bypass duct in 2002, featuring special sound-attenuation treatment of the inner skin. FACC worked with Pratt & Whitney Canada (P&WC, Longueuil, QC, Canada) to develop the CFRP bypass duct for the PurePower PW800 engines — selected for the Gulfstream G500 and G600 business jets — and began serial production in December 2014.

Composites also could see use in a bladed spinner proposed as part of Rolls-Royce’s Vision20 (two decades out) strategy. Currently, spinners do not have blades and might or might not be made from composites.

As Rolls-Royce refines the CTi fan’s robotic ATL, the GE Global Research Center in Munich, Germany, is endowing composites manufacturing robots with mathematical modeling skills, real-time 3D laser scanning, computer vision analytics and other sensors. “Eventually our instruments will be fully integrated into the brains of these machines,” explains researcher Stefan Van Nieuwenhove, referencing the preform weaving and RTM machines used to produce LEAP engine blades. The machines will then know how to react to changes in the manufacturing process — what GE calls “adaptable manufacturing.”

Hybrid blades and high-temp BMI ducts

Blades in the GE9X turbofan that will power the Boeing 777X and enter service in 2020 will be the first to use a hybrid of carbon and glass fiber in the same resin. Reportedly, 5-10% of the fibers will be glass, helping GE’s longest and widest chord blades yet meet the critical bird strike test, thanks to glass fiber’s higher failure strain, which enables it to flex before it fractures. A new, higher strength carbon fiber also will be used and a steel alloy will replace titanium in the leading edges. This new, more swept, 3D aerodynamic design — the same description used for Rolls-Royce CTi blades — allows for thinner GE9X blades but also two and six fewer blades, respectively, than the GEnx and GE90-115B engines. This lower fan blade count and new blade design enables a faster fan tip speed, which improves the low-pressure (LP) turbine efficiency so that blade count can be cut there as well. The GE9X forward fan case and rear fan frame also will be a composite, designed and built by Safran using the 3D woven preform technology it has perfected in LEAP. Although it is GE’s largest fan diameter yet, at 3,400 mm, using CFRP in the fan case saves almost 160 kg.

According to Nick Kray, a composites consulting engineer for GE Aviation, these hybrid blades open the door to other combinations including integrating different CF forms — such as uni tapes, braids and wovens — into different areas of the same blade. Kray believes hybrid materials are not limited to the fan section. He says the engine’s airflow path surfaces, which are not heavily loaded, could be composite, with future hybrids even replacing high-temperature metals in certain areas. Kray also sees potential in the 200-425°C compressor section within the engine core, where a high-temperature composite could increase design flexibility. However, noting the 25 years of R&D before ceramic matrix composites (CMCs) replaced metals in high-temperature turbine shrouds and combustor liners, Kray concedes a similar timeline might be necessary.

That said, high-temperature composites have indeed moved beyond the fan, in the GEnx variable bleed valve (VBV) ducts. Located at the exit of the fan module, 10 of these structures were developed by EDO Fiber Innovations (Walpole, MA, US) from carbon fiber-reinforced bismaleimide (BMI). They are able to withstand internal pressures at high temperatures and resist oxidation, yet weigh only 3.6 kg per set. The complex-shaped parts were made with three layers of braid and were matched-mold RTM’d to ensure accurate, high-quality interior and exterior finished surfaces. Now manufactured by Harris (formerly Exelis, Salt Lake City, UT, US), 11 different VBV ducts incorporate the company’s most complex braids and will reach 12 shipsets/month at Boeing 787 full-rate production. Harris also uses braids to produce the 1m-diameter by 60-mm-wide CFRP flow path spacer, located just aft of the GEnx fan.

Another CF/BMI part is the mixed flow nozzle (MFN) on the SaM146 engine that powers the Sukhoi Superjet 100 regional jet, which entered service in April 2011. Designed and produced by Safran subsidiary Herakles (Le Haillan, France), the large tube is 30% (20 kg) lighter than its metal counterpart and its inner lining is pierced with 160,000 tiny holes that “trap” sound waves inside its composite honeycomb structure.

Integrated propulsion system

As engine designers seek every percentage point of greater efficiency possible, it makes sense that optimization of nacelles would follow. The LEAP 1-C engine set for the COMAC C919 will feature a next-generation nacelle designed and built by Nexcelle (Cincinnati, OH, US), a joint venture between GE Aviation’s Middle River Aircraft Systems (Middle River, MD, US) and Safran’s Aircelle (Gonfreville l’Orcher, France). Described by Nexcelle president Michel Abella as “the first truly integrated propulsion system,” its structure, he says, was designed concurrently with the engine’s main structure and part of the engine pylon. This radical approach cut out excessive conservatism typically built into nacelle and pylon systems when designed separately. Coupled with low-mass, integrated composite structures that improve aerodynamics, IPS’ innovations are projected to cut LEAP 1-C fuel consumption by an additional 2%.

IPS replaces a conventional thrust reverser’s two-piece “D” doors with a one-piece, composite O-Duct, which slides aft to reverse thrust. This eliminates the maintenance-prone D-door latches and smooths bypass airflow, improving fuel consumption and boosting thrust-reverser efficiency by as much as 10%. Nexcelle says the O-Duct’s single-piece CFRP inner skin (see Fig. 3a & b) is a key feature, made at Aircelle’s Le Havre, France, facility using an innovative molding process new to this program. Although it has released no additional details, Aircelle claims it has mastered the RTM and 3D RTM processes, the latter using 3D woven preforms. As a Safran subsidiary, it knows well the process used to make LEAP blades and other parts. Aircelle says it already uses RTM for Falcon 7X/8X and Airbus A320neo nacelle systems.

Another key IPS feature is the low-drag front end, which replaces the traditional multi-piece aluminum lip, forward bulkhead and outer barrel assembly with a single, seamless composite structure, eliminating discontinuities so that laminar flow extends to the composite aft bulkhead for improved aerodynamics. The inner barrel also is a one-piece composite, with an integrated acoustic treatment that helps meet noise reduction targets. In fact, the new structures’ simplicity has provided 10-20% more surface area for acoustic treatments in the airflow path. The IPS is reportedly 80% composite materials by weight, up from 70% on Nexcelle’s previously most advanced nacelle, which flies on the Airbus A380.

Further integration

And what of the future? In his 2014 analysis of aeroengine technologies needed for 2035-2050 and beyond, Meyer Benzakein, retired aeroacoustics and combustion researcher for GE and director of the Propulsion and Power Center at Ohio State University (OSU, Columbus, OH, US), listed propulsion airframe integration as a key R&D goal that will demand slim-line/laminar-flow nacelles, adaptive fan blades, distortion-tolerant fans and multi-degree-of-freedom acoustic liners. Composites, indeed, are enabling all of these elements, and proponents of CFRP are battling to carve out their share of the estimated $3 trillion market in aircraft engine development between now and 2030.

Related Content

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreCorebon, Composite Braiding partner to enhance TPC manufacturing

Collaboration aims to overcome production limitations with tubular thermoplastic composites (TPC) by using induction-heated tooling and high-quality commingled braids.

Read MoreNoble Gas Systems 350-bar conformable pressure vessels pass HGV2 standard tests

Conformable tanks with new materials pass technical tests for hydrogen storage, to compete with Type IV pressure vessels using CFRP.

Read MoreRead Next

Composites in commercial aircraft engines, 2014-2023

The drive to boost aircraft operating efficiency continues to fuel adoption of polymer matrix composites in jet engines.

Read MoreAeroengine Composites, Part 1: The CMC invasion

As pressure for commercial aircraft fuel efficiency continues to mount, ceramic matrix composites evolve as they battle metals for application in the engine hot-zone and elsewhere.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More