A bead of sweat ran down the middle of my back. I had been in a conference room for nearly three hours concluding a high-stakes negotiation, with the future of a multi-billion dollar company’s expansion resting squarely on the solution I was proposing. The product I was selling at the time was dry carbon fiber. I had invested years learning my customer’s businesses, listening to what their pain points were, identifying problems they hadn’t seen and recommending innovative solutions to their problems. Years later, I found myself using this knowledge to breathe life into an existing product — preimpregnated composite fibers — that would further transform my view of the composites industry forever, and potentially help that customer and others like them expand into the marketplace. In this article, I want to share what I learned during my career to summarize the winning attributes of preimpregnated products.

Preimpregnated fiber reinforcements enable a company to manufacture lower cost products, increase throughput, enhance product performance and improve quality and worker safety, resulting in immediate payback. If your company is filament winding, using automated tape laying (ATL), laying up by hand, tube rolling or compression molding, chances are prepreg and towpreg products can improve the manufacturing process. The benefits are realized no matter if the company is consuming millions of pounds or even the smallest amount of material.

I will illustrate direct and useful comparisons for how fabricators can benefit from prepregs, assessing them against more traditional forms of composites production. I will focus on five key areas: efficiency, quality, performance, safety and profitability. In each area, I will present a high-altitude view of where prepreg products fit in the composites industry and explain their benefits across multiple manufacturing processes. In the end, I hope you will be able to appreciate that the value of prepreg materials greatly exceed their cost.

Efficiency

Years ago, as a carbon fiber salesperson, I sat in a room filled with automotive executives negotiating the price of carbon fiber. Their sole focus was to justify why a $5-per-pound carbon fiber price would place the material in such high demand from the automotive industry that it would exhaust the world supply.

The automotive executives were so focused on carbon fiber price — in their minds, the largest raw material input — that they ignored the largest cost component that would ultimately determine whether using this material was viable: efficiency.

During that meeting, I stated something ironic: Even if carbon fiber were free, it was still unlikely that auto producers could afford it. Then I explained that metal-stamped hoods required seconds to manufacture, while molding carbon fiber hoods took, at best, minutes. With a bottleneck like that, it would be difficult to meet automotive production targets. To this day, that company has not used one single pound of carbon fiber for automotive body panels. In the meantime, the inflation-adjusted price of carbon fiber has fallen well below that $5 per pound threshhold.

The point of this anecdote? Many companies focus on the price of prepreg, ignoring the efficiencies it enables. Further, although curing carbon fiber composites still remains a relatively long process for automotive hoods, it is critical to understand that efficiency plays a huge role in determining the total cost of a part.

For example, in filament winding, efficiency has a large impact on the output of a factory. In this process, as winding speeds increase, air is driven into the resin bath, creating voids and reducing mechanical performance in the final part. Fully wetting out tow bundles can only be achieved at these relatively low speeds. As a result, stable wet filament winding can achieve speeds of about 1 meter per second.

Comparatively, prepregged tow, or towpreg, has been shown to run as fast as 5 meters per second. Towpreg also reduces voids by eliminating the need to wet out a resin bundle.

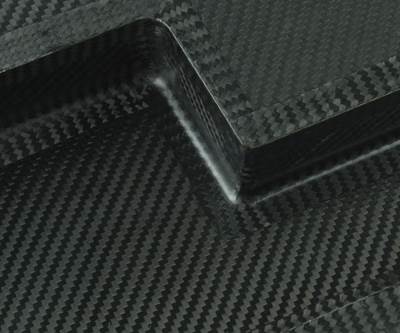

Laminate using wet winding with voids on the left (top) compared to a near void-free laminate created with towpreg (bottom). Source | TCR

We can look further into the supply chain to uncover more efficiency improvements. If a filament winder uses a wet process, during a normal production shift an operator mixes resins with a pot life of 6-8 hours, which are designed for a shift of use. At the end of the shift, cleanup is required, which includes washing out resin baths, cleaning resins off guide rollers, measuring resin levels, taking inventory, and a host of other tedious but necessary actions. During these setup and tear-down periods, operators are not manufacturing products. If an operator spends one hour per shift doing this, it totals 250 hours of lost time, or 6 weeks of work time for one worker per year.

With room-temperature towpreg, this setup is eliminated. Operators begin their day by placing the spools on the creel racks and immediately running product.

Similarly, with room temperature-stable prepregs, companies also enjoy switching off machinery when they want, and picking back up days later where they left off. There is no need to wait around until the prepreg thaws, record temperatures and refreeze material. Operators simply grab material and begin working. This time is recaptured in pure manufacturing output.

Another path to prepreg efficiency is through the modification of tackiness. For example, a resin’s tackiness can be moderated so that a braided prepreg can be easily maneuvered around difficult angles without sticking to a mandrel. In this way, fabricators manufacturing ducting or complex tube structures can gain enormous throughput efficiencies compared to use of woven fabrics.

Supply chain efficiency is streamlined even further when inventory calculations are finished in minutes, with fewer products — resins, catalyst, floor paper, mixing container and more — to count and monitor. Purchasing managers can ensure products are in stock, managing fewer vendors.

Further, the resin mixing, staging and inventory rooms necessary for wet molding processes are also not required for prepregs, which allows a company to decrease its operational footprint, or at the very least, use the existing footprint for further capacity expansion with partmaking equipment. Additionally, since machines are being used to produce products during the full shift, machinery utilization rates skyrocket, which drives down the requirement for new equipment and the potential for increasing CAPEX.

In real-world examples, we have witnessed a 20% increase of throughput from customers implementing prepreg products over their wet winding or wet layup alternatives. Since work time is reduced, there is also a direct correlation to labor, allowing more to be accomplished with fewer workers.

Focusing on using prepreg, a fabricator can increase the output of its facility, decrease labor, make more efficient use of the operational footprint and drive unit costs lower.

Quality

One of the most important manufacturing processes for many fabricators is quality control. Aerospace, defense, energy storage, oil and gas, healthcare and other end markets demand quality and traceability. The cost of measuring and managing quality is born by most fabricators using traditional in-house QA labs.

Even at my company, there are multiple QA procedures in place during the production of prepreg. These procedures use a number of different technical methods to verify the resin is correctly mixed, with multiple personnel performing checks before resins are blended. Once accepted, a resin then must make three trips through the the laboratory for quality checks. Many methods are in place to remove uncertainty and ensure accuracy and repeatability, including the use of FTIR (Fourier transform infrared) spectroscopy. This instrument uses light to scan and produce a fingerprint of the resin to ensure accuracy. This is done before any resins are placed on reinforcements.

Product is then manufactured on custom machinery, built in-house. This allows tight control over the application of the resin to the reinforcement. As the prepreg product is formed, it then proceeds to QA labs for final approval. Each lot contains a Certificate of Conformity, which outlines the resin content of every spool of prepreg and towpreg. Customers can trace the exact spools and resin content of those spools back through to each part that was produced.

To further maintain quality control and consistency, prepreg production is done in a temperature- and humidity-controlled environment. This diminishes aspects of variability usually present in other manufacturing environments.

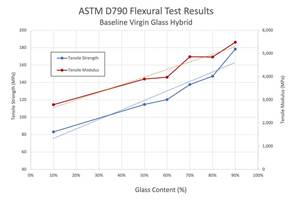

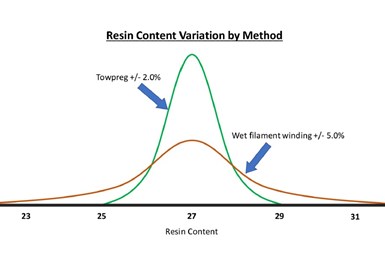

Quality inherently finds its way into the production of parts. In typical wet winding and wet layup, the amount of resin applied to the fiber reinforcement varies far more than it does during the manufacture of towpreg and prepreg. In traditional wet winding and layup, measured resin variation can usually be controlled to ±5.0% COV (coefficient of variation). This large variation is usually accounted for with higher design allowables.

Resin content variation by method. Source | ??

By comparison, prepreg products typically maintain resin content to ±2.0% COV. By monitoring these levels with tight tolerance, the desired fiber volume is assured. This allows for use of tighter design allowables, which leads to faster wind times, reduced material use, faster cures, reduced part weights, thinner parts and other benefits.

In conclusion, the quality and consistency of prepreg allows for the production of more consistent parts with higher repeatability and minimized part rejections.

In my next column, I will examine how prepreg achieves higher degrees of performance and insures greater worker safety.

About the Author

Brian Bishop

Before joining TCR Composites in 2019, Brian Bishop has had the privilege of working with two of

the top advanced composites companies in the world. He has been in the advanced composites business for 20 years, traveling the world marketing and selling materials to some

of the world’s largest corporations. He excels at identifying industry problems and implementing solutions to overcome them. His life is wonderfully balanced with his wife and children in Austin, Texas.

Related Content

High-efficiency, low-energy industrial ovens, furnaces and washers

CAMX 2023: International Thermal Systems (ITS) offers a range of equipment that maximizes manufacturing efficiencies and minimizes energy consumption that include OOA composite curing ovens.

Read MorePilot program turns EOL wind blades to liners for pipe infrastructure

TPI Composites, Tex-Tech and Carbon Rivers partner to process wind blades, pyrolyze the material and use the recovered glass fibers to give new life to damaged existing pipelines.

Read MoreDLR completes MFFD upper shell skin layup

Eight-meter-long CFRTP fuselage skin was achieved via laser-heated in-situ consolidation, with stringers, frames and cleats to be welded.

Read MoreAbaris selects Premier ESR to optimize composite cure cycles

Encapsulated sample rheometer (ESR) by Alpha Technologies will be incorporated into Abaris’ service and consultation business to characterize a variety of composite material specimens.

Read MoreRead Next

New Composites Evolution prepreg cures at low temperature

This low-temperature, 12-hour-cure tooling prepreg is the latest product in Composites Evolution’s Evopreg EPT tooling epoxy range.

Read MoreSolvay launches epoxy prepreg for aerostructures compression molding

Solvay Composite Materials has launched CYCOM EP2750, a new highly drapable epoxy prepreg designed specifically for the compression molding of high-quality, high-rate, cost-effective primary and secondary aerostructures.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More