Renishaw Spotlights Process Control and Additive Manufacturing Solutions

Renishaw technologies aimed at helping global partners apply high levels of automation and connectivity to their production processes.

Renishaw Inc. can be found in two locations here at IMTS. According to Jeff Seliga, marketing manager, the company is focusing primarily on its expertise in smart factory process control and additive manufacturing solutions—both hot topics in manufacturing today.

Quality Assurance – Booth 135509

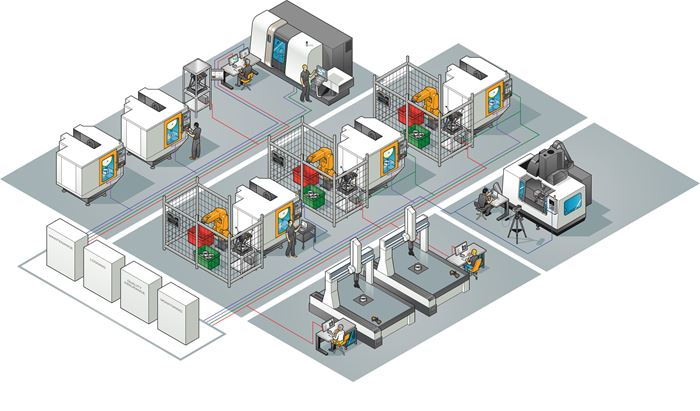

On display at Renishaw’s main booth in the Quality Assurance pavilion is a high-productivity machining cell, featuring fully-integrated process control. Attendees can see how high levels of automation and connectivity can be incorporated into CNC machining operations to improve productivity and process capability.

It is also the place to see new advancements to Renishaw products like the Equator gaging system. The new Equator 500 gives users more flexibility in a wider range of applications for larger parts. The new IPC (intelligent process control) software automates process control and offset correction directly from any Equator gage to the CNC machine.

The latest developments in other Renishaw software, like MODUS 2 software for CMMs and Equator gaging systems, smartphone apps for on-machine probing and CNC controller-based apps for probing and reporting, are also on display.

Additive Manufacturing – Booth 431607

In the 3D printing and Additive Manufacturing pavilion, Renishaw is showcasing its latest AM system and software. The new multi-laser RenAM 500Q increases productivity in the most commonly-used machine platform size. The company’s suite of AM software includes QuantAM build preparation software, InfiniAM Central remote process monitoring, and InfiniAM Spectral for live feedback on energy input and emissions from the AM build process.

Related Content

-

Optimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

-

How AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.

-

Bio-inspired EV underbody panel developed by TPI Composites, Helicoid Industries

Composite underbody panel for battery pack protection, made of stacked multiaxial noncrimp fabric, will serve high-volume commercial and automotive markets.

.jpg;maxWidth=300;quality=90)