Researchers introduce capillary-driven method for continuous fiber 3D printing

The LITA 3D printing system from the University of Delaware shows potential for in situ cure for high-performance carbon fiber composite parts.

Source | University of Delaware

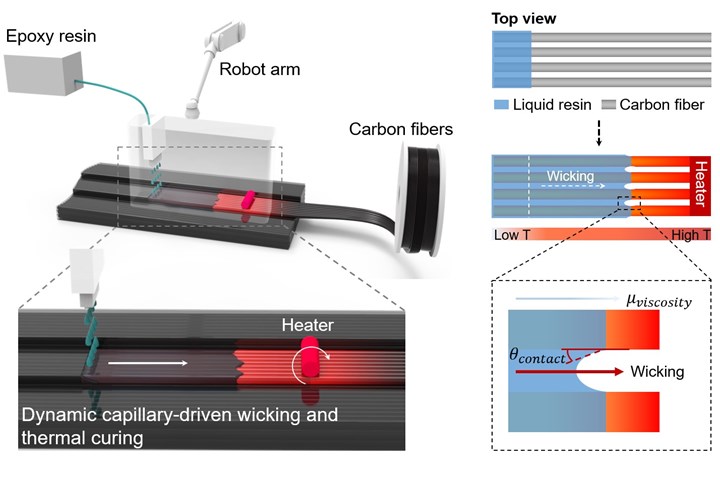

New research in continuous-fiber 3D printing shows potential for additively manufactured composite parts for a range of industries — including space. Published in the academic journal Matter, researchers from the University of Delaware’s (Newark, Del., U.S.) Center for Composite Materials (CCM) recently introduced a lab-scale method for continuous-fiber 3D printing that incorporates robotics and a capillary-based, in situ heat cure system for fast, additively manufactured carbon fiber composite parts using high-temperature thermoset resins.

“We call it one-step 3D printing,” says Dr. Kun Fu, assistant professor at the University of Delaware and an author on the study. Called the localized in-plane thermal assisted (LITA) 3D printing method, the system comprises an all-in-one printhead mounted on a robotic arm that includes carbon fiber dispensed from a spool, a guiding bar, a liquid resin nozzle and an electric heater. As the fiber is placed onto the part surface, liquid resin is sprayed onto the fibers and is immediately followed by the heater, which, Fu explains, both aids in infusion and in curing of the part. Fu adds that the heating process reduces the viscosity of the room-temperature resin, helping it to infuse into the fibers without need of a vacuum along capillaries, or tube-shaped gaps, between the fibers. Depending on the needs and size of the part being manufactured, Fu says, the temperature of the heater can be increased or reduced to control the viscosity of the resin.

The current, lab-scale LITA 3D printing system. Source | University of Delaware

This method reportedly enables nearly simultaneous wetting and curing of continuous fibers with thermoset resins, with potential to quickly producing 3D composite components with complex geometries and the high mechanical properties that come from continuous fibers and high-temperature thermosets. The researchers have also demonstrated the system can be used for horizontal and vertical printing, Fu says, and on planar or curved surfaces, adding to the system’s flexibility.

“The technique has been very promising so far,” Fu says, “and as far as we know, we’re the first to publish a technique like this.” According to Fu, the researchers are in the process of obtaining a patent for the technology.

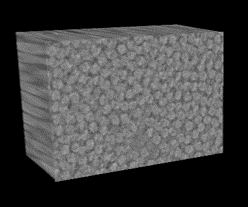

3D CT image of a composite produced with LITA 3D technology. Source | University of Delaware

In addition, the University of Delaware and partner KAI (Dallas, Texas, U.S.) recently received a NASA grant to use the LITA 3D printing method for manufacture of continuous carbon fiber-reinforced composite components for thermal protection systems on NASA spacecraft and lander systems. Fu says that the LITA 3D printing system was chosen for its ability to print with high-temperature resins.

Currently, the technology has only been demonstrated at a small scale – 3K carbon fibers were used for the study – but Fu says the team is working to scale up the robotic system to enable use of wider carbon fiber tows for larger components. The researchers are currently looking for companies interested in collaborating on scale-up and subsequent commercialization of the technology.

To access the Matter article, go to www.sciencedirect.com/science/article/pii/S2590238520301818.

Related Content

Pultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;width=70;height=70;mode=crop)