Resins for the Hot Zone, Part II: BMIs, CEs, benzoxazines and phthalonitriles

Next-generation aerospace programs demand higher temperatures for structural and hot-section components, fostering advances in thermoset resin chemistry.

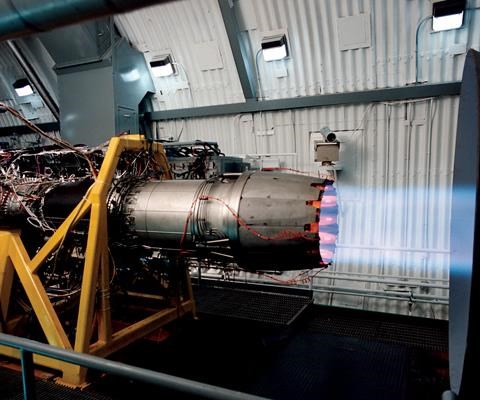

Today, the rigors of flight demand robust materials that can handle thermal extremes: military aircraft require thousands of hours of service from engine nozzles that see up to 750°F/399°C, and spacecraft and missiles must endure short-duration launch and re-entry temperatures to 1500°F/816°C. Though it’s no small feat to compete with well-developed and still-evolving epoxy chemistry in aerospace components, other thermoset resins are expanding the high-temperature operations regime. In Part I of this two-part series, HPC offered an update on the earliest and most widely used of these high-temperature alternatives, the polyimides (see "Editor's Picks under “Learn More,” at right). Here, in Part II, we do the same for bismaleimides (BMIs), cyanate esters (CEs), benzoxazines and phthalonitriles. Not as widely used as polyimides, this group of resins in composites is gaining traction because they offer aerospace engineers a broader palette of tailorable matrices from which to choose when called on to meet thermal challenges within program cost targets.

Battle dress for BMIs

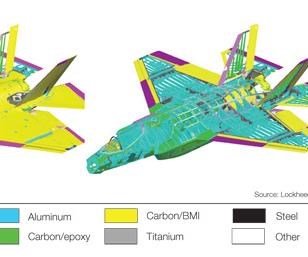

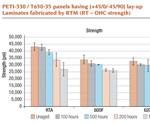

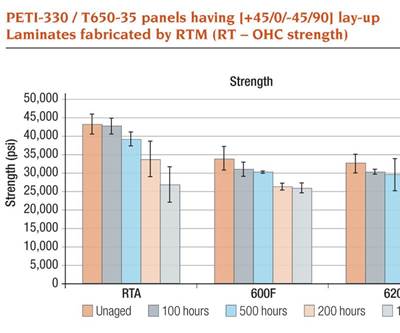

Close relatives of the polyimides, BMIs offer temperature performance and price between that of polyimides and epoxies and, because they cure by addition reaction rather than condensation reaction, they mitigate problems with emitted volatiles. For these reasons, BMIs have served on military aircraft for decades and into 5th Generation fighter planes, such as Lockheed Martin’s F-22 Raptor and the F-35 Lightning II Joint Strike Fighter. Although the air-to-air F-22 program has been canceled in favor of the air-to-surface-oriented F-35, considered more useful in foreseeable military engagements, the Raptor’s airframe has served as an important test bed for BMI processing technology, and is about 25 percent composite by weight, split 50/50 between reinforced epoxy and BMI resins. The F-22’s BMI accommodated application of resin transfer molding (RTM), including RTM internal ribs and spars, parts with "T" of "I" cross-sections. (The exterior skins are either hand layed or automated tape layed, using IM7/5250-4 BMI prepreg from Cytec Engineered Materials of Tempe, Ariz.) The closed-mold process produced parts with multiple finished surfaces that enabled secondary bonding, and its high injection pressure helped avoid ply bridging in deep draws and sharp corners.

CYCOM 5250-4 BMI resin from Cytec provided a high rate of reproducibility by RTM in nearly 400 high-strength, tight-tolerance composite components on the F-22. Cytec has invested considerable effort in BMI formulations, including CYCOM 5250-4HT, which reportedly has a glass transition temperature (Tg) of 630°F/343°C. This represents a 100°F boost in Tg over CYCOM 5250-4. Cytec says its service temperature is 400°F/204°C. CYCOM 5250-5 BMI is designed to offer ease and consistency of processing comparable to epoxies, but with the Tg/service properties of 5250-4. Toughened CYCOM 5261 BMI prepreg pushes the toughness envelope achieved with high-toughness epoxies, but again, to the 630°F Tg of CYCOM 5250-4.

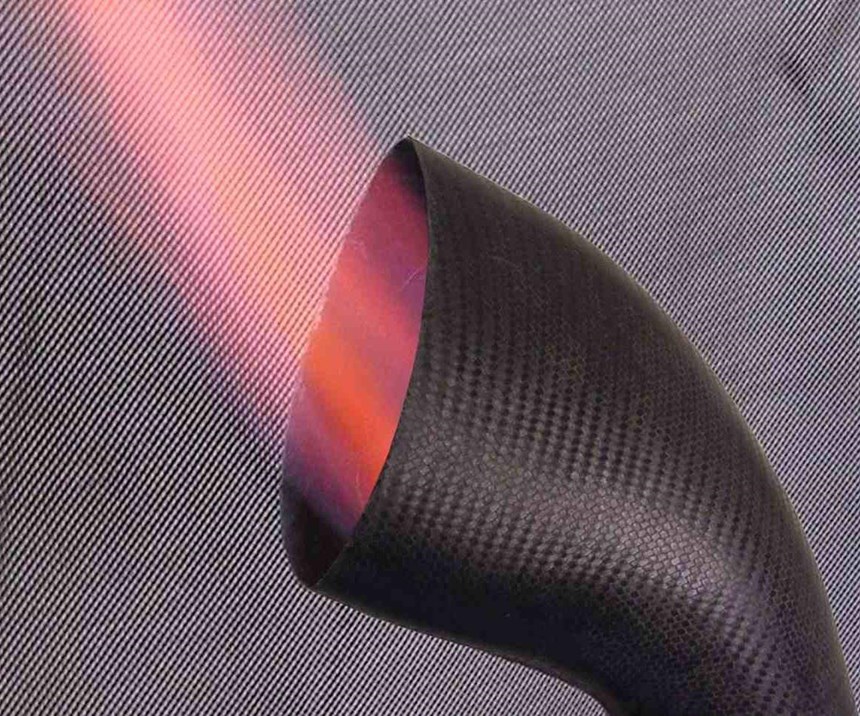

The F-35, now in development in three variants (conventional take off/landing or CTOL, short take off/vertical landing or STOVL, and carrier configuration), also uses CYCOM 5250-4 BMI in carbon fiber prepregs. To date, all carbon fiber/BMI components on the F-35 are autoclave-cured. While some smaller parts are hand layed, larger parts, such as the upper and lower wingskins and engine nacelle skins, are fabricated via automated fiber placement (AFP). Lockheed reports that after some initial degradation in lay-down rates due to low resin tack and slit tape cleanliness, the BMI fiber placement process now shows significant labor reduction. AFP reduces the potential for errors in complex ply definitions through repeatable NC programming, and it improves fiber orientation by eliminating the tendency for hand-layed fiber to follow the natural path on part contours. AFP also maintains the F-35 concept of ‘digital thread’ by linking the engineering model directly to automated fabrication.

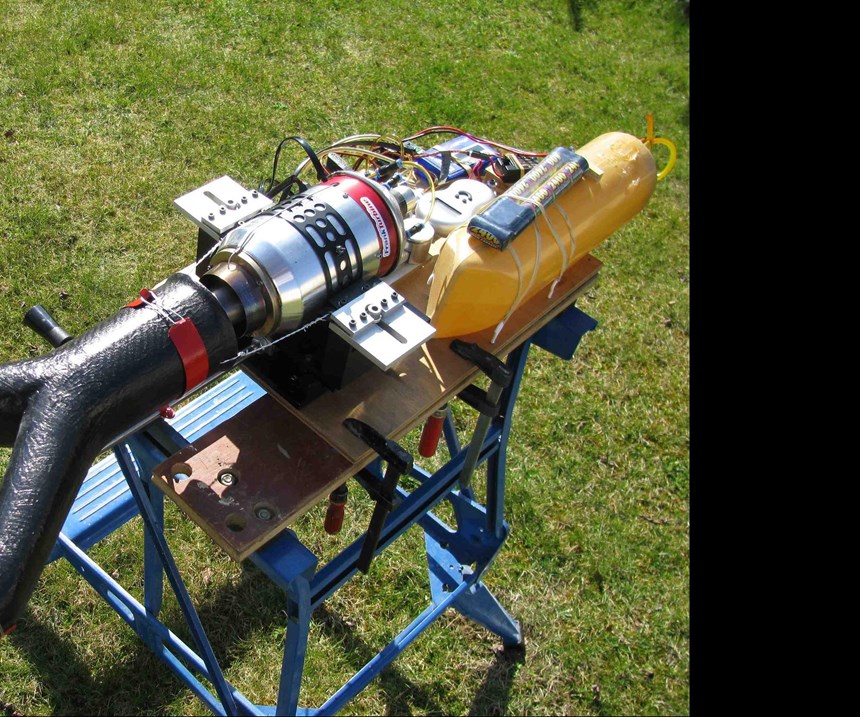

Depending upon the variant, 20 to 30 percent of the F-35 airframe structural weight is composite, with well over 50 percent of that weight in carbon fiber/BMI. This material system is considered extremely important in the F-35 team’s effort to replace metal and meet air vehicle weight requirements. The extended timeline of the F-35’s 10-year System Design and Development (SDD) phase has enabled evaluation of new materials and process advancements, such as those developed in Small Business Innovation Research (SBIR) programs. A recent SBIR example is Quickstep Holdings Ltd. (North Coogee, Western Australia) work with Vector Composites (Dayton, Ohio) to develop an out-of-autoclave cure cycle for carbon fiber/BMI components. “Considering the potential high rate of production planned for this aircraft,” says Dale Brosius, Quickstep’s U.S.-based COO, ”a process that can shorten overall cure cycle and get it out of the autoclave could greatly reduce recurring manufacturing costs and overall tooling investment.”

Another SBIR effort, funded by the U.S. Air Force Research Laboratory (AFRL) to develop BMI repair materials, has resulted in commercial BMI resins for both autoclave and out-of-autoclave cure. Linas Repecka and Robert Stratton, cofounders of Raptor Resins Inc. (Celina, Tenn.), completed the SBIR effort last year and have taken that chemistry commercial, offering BMIs primarily designed for resin film infusion (RFI) processes. Key products include autoclave-cure BMI-1 resin with a Tg of 560°F/293°C and two out-of-autoclave formulations: BMI-2 and BMI-1OOA. Repecka says BMI-2 cures at 325°F/163°C but demonstrates a Tg of 700°F/371°C. BMI-1OOA is said to be as tough as BMI-1 and consistently meets or beats low-void-content expectations.

“These resins are low cost, starting at $50/lb,” Repecka points out, noting that they also “make excellent tackifiers and binders for preforms.” Unlike most prepregs, Raptor’s BMI infusion resins are storage-stable at room temperature for as long as 24 months. “We are attempting to change the assumption that BMIs are expensive and only used when service temperatures are high. We don’t believe either is true,” Stratton comments.

Initial applications for Raptor Resins’ BMIs have been composite tooling and oilfield applications, although Repecka reports a number of aircraft OEMs have these formulations under evaluation.

BMIs are beginning to make an impact outside military aviation. For example, the thrust reverser structure on Gulfstream Aerospace Corp’s (Savannah, Ga.) G450 business jet requires heat resistance and thermal stability to 450°F/232°C for short duration. Answering the call is HexPly M65 toughened BMI from Hexcel (Stamford, Conn.). This two-part addition-reaction formulation offers positive fabrication behavior in cocure over honeycomb core, as well as in compression molding, filament winding, AFP and automated tape laying processes. HexPly M65 is optimized for tack and, in processes using prepreg (including AFP), helps significantly reduce fiber fuzzing during laydown.

Hot flight to cold void

Although BMIs have proven themselves in missile and space vehicle applications, where extremes of heat at launch can be followed by exposure to extreme cold in space, the current newsmakers are cyanate esters, in large part because of their resistance to moisture absorption. Composite strakes, fins and nose radomes on AMRAAM, Sea Sparrow and AARGM missiles feature BMI and CE resins in prepregs from TenCate Advanced Composites (Morgan Hill, Calif.) and its wholly owned subsidiary, YLA (Benicia, Calif.). In its EX-1505 formulation, the supplier capitalizes on the backbone chemistry of cyclotrimerized three-dimensional triazine rings, created during cure in cyanate esters to combine low moisture absorption with high heat resistance — to 800°F/427°C, depending on the application structure. Reinforced with quartz fibers, EX-1505 exhibits positive dielectric performance in missile electronics, and optimally forms insulative char during high aerodynamic heating.

In orbital spacecraft, TenCate resins reportedly have excelled since 1994, including in the heat shields on all Mars mission vehicles. Now in testing and evaluation is the company’s EX-1505T CE prepreg, designed for the higher heat regimes of Earth atmosphere re-entry, with a dry Tg of 682°F/361°C. Full commercialization of the product is expected by year’s end.

Primaset cyanate esters produced by Lonza Inc. (Basel, Switzerland) have been used in composite satellite antennae and missile components for aerospace products from Boeing, Raytheon, Sunstrand and others. The supplier’s dedicated cyanate ester production plant in Visp, Switzerland, can manufacture 2.5 million to 5 million lb/yr. Saja Das, Lonza’s Allendale, N.J.-based director of sales and marketing, says that temperature-resistance requirements for these materials in missile applications range from 500°F to 700°F (260°C to 371°C), “with next-generation missile and weaponry systems boosting this heat resistance target up to 1,000°F/538°C.” Primaset also is being tested in the F-35 composite radome system and has been used in gearboxes located near commercial aircraft engines, where CE-based composite is subjected to 500°F/260°C. Available in solid, liquid and solvated form, Lonza CEs offer processing flexibility through formulations for RTM, VARTM, RFI, ATP and prepregging.

“Primaset CEs exhibit the familiar handling properties of epoxy or polyurethane. The inherent tackiness of CE prepregs enables fabricators to make complex parts, using inexpensive low-pressure and low-temperature vacuum bag molding/curing,” says Das. “In 100 percent liquid form, we can tailor these resins for toughness, microcrack resistance during high thermal cycles, and low viscosity, while still maintaining bondability to honeycomb core.”

Recent toughened CE formulations include BTP 6020 and BTP 2500. BTP 6020 copolymerizes CE and thermoplastics that demonstrate stable structure during crosslinking, low dielectric properties at very high frequencies and improved moisture resistance. With a Tg of >530°F/277°C, this formulation is in qualification on a number of high-temperature aerospace programs. BTP 2500 provides low viscosity for bonding and good peel strength in sandwich structure.

Promising research in CE resins is being conducted at the Naval Research Laboratory (NRL) in Washington, D.C. According to Dr. Teddy Keller, head of the Advanced Materials/Chemistry Division, NRL has the only high-temperature polymer synthesis program among the U.S. Department of Defense (DoD) laboratories. He explains synthesis as the manipulation of chemical and physical properties in compounds to create reactions that yield new compounds. For CEs in composite aerospace components, the ideal synthesis would result in a thermoset resin with high thermal and oxidative stability and low cure temperature, processed from a liquid CE resin. In NRL’s synthetic method, oligomeric aromatic ether spacer groups are introduced with random lengths between terminal reactive CE groups in the monomer to create liquid CE resins that can be processed by RTM, RFI, pultrusion and filament winding at ambient temperature under controlled conditions. This research indicates that it is possible to achieve much higher thermo-oxidative stability in CE composites than can be achieved in epoxy-based composites and to control the rigidity, crosslinking density, dielectric constant, Tg and other desirable physical properties, based on adjustments in the relative quantities

of reactants.

Meanwhile, research into CE chemistry at the Naval Air Warfare Center, Weapons Div. (NAWC, China Lake, Calif.) has included examination of the effects of thermoplastic toughening agents, such as polycarbonate. Toughened CEs can improve upon already low moisture absorption properties and enhance microcracking resistance. Andrew Guenthner, head of the NAWC China Lake Polymer Science and Engineering branch, describes the goal of this research as “advancing the readiness level of material with good intrinsic resistance to moisture. We have been surprised to learn that even very slight changes in cyanate ester molecular structure result in significantly reduced water absorption. We believe this is an indication of further improvements that can be made without sacrificing affordability or ease of processing.”

Wide processing window

Another “hot zone” alternative, benzoxazine, features chemistry akin to that associated with phenolics. Overall, benzoxazines provide low melt viscosity that enhances processing, but delivers a composite with low moisture absorption and low shrinkage. Further, the resins demonstrate notable fire retardance and dielectric properties.

At Huntsman Advanced Materials (The Woodlands, Texas), research into the chemistry of different phenols that can be used to formulate benzoxazine has suggested possible enhancements to thermo-oxidative and hot/wet performance of composites — reportedly better than those achieved for epoxies and on par with improvements seen in CEs. Corrosion resistance and good dielectric properties are additional performance benefits of this resin. Huntsman also is examining halogen-free bisphenyl A- and F-based benzoxazines for cocuring or as an epoxy hardening additive. The company received a 2009 JEC award for the development of a carbon fiber/benzoxazine formulation used in bipolar plates for fuel cell applications.

Also on the benzoxazine hunt for market niche is Henkel AG & Co. KGaA (Bay Point, Calif.), with its Epsilon formulations. Although these resins are engineered for “standard” aircraft service temperatures (to 350°F/177°C), chemistry that can handle higher temperature reportedly is possible. Patrice Buisson, Henkel’s director of global marketing and business development, highlights the cost and weight savings of its 99100 formulation for RTM and VARTM processes as compared to BMI and epoxies. Henkel also has developed a synergistic binder, Epsilon 990, that facilitates preforming with the 99100 resin.

Henkel contends that its Epsilon resins demonstrate open hole compression strength retention of >95 percent (180°F/82°C wet). Cure exotherm is lower than for epoxy resin, allowing fabrication of thicker sections and longer injection time for large parts. Low minimum viscosity (less than 100 centipoise) can be maintained at 212°F to 320°F (100°C to 160°C) to provide a wide processing window. In answer to customer demand for a benzoxazine processable by resin film infusion, Henkel expects to commercialize such a formulation in the next year that could reduce cure cycle time and temperature from the current 365°F/185°C over three hours.

Phthalonitrile’s magic Tg

For composite missile components that require outstanding compression and shear strength properties during short-term use at temperatures as high as 1500°F/816°C, phthalonitrile resin offers a viable option. Examination of phthalonitrile synthesis methods by NRL’s Keller and colleagues over the past 20 years has focused on reducing the environmental effect of moisture content on Tg and enhancing processing flexibility for methods such as RTM and RFI while maintaining thermal oxidative stability and mechanical properties. Formulations are tailored with variable length, oligomeric aromatic ether spacer groups end-capped with phthalonitrile units to create resins with low melting points, from 104°F to 122°F (40°C to 50°C), and a corresponding process window with a high threshold of >392°F/200°C.

Perhaps most important in the course of this research, NRL has synthesized phthalonitrile-based thermosets that reportedly exhibit no softening at service temperatures as high as 932°F/500°C, when initially cured at 482°F/250°C and postcured at up to 896°F/480°C in an inert atmosphere. In carbon fiber composites, this translates to very low knock down in strength properties at elevated temperatures and very low volatile emissions. This unique miscibility behavior could prove useful in missile components that see exposure to temperatures of 700°F to 1000°F (371°C to 538°C) for up to eight minutes.

Most recent phthalonitrile research at the NRL is focused on the formation of crosslinked polymer chain networks through resin blends to further enhance dynamic mechanical properties. At temperatures in excess of 1022°F/550°C, the thermosets are converted into carbon with charred residues >80 percent at 1832°F/1000°C.

Among the current group of U.S. phthalonitrile suppliers is Maverick Corporation (Blue Ash, Ohio), which has patented its own MVK-3 phthalonitrile formulation and scaled up its manufacturing process. MVK-3 formulations can be RTM/VARTM processed and also are available as prepregs from Renegade Materials Corp. (Springboro, Ohio). Another supplier is JFC Technologies (Bound Brook, N.J.).

Evolutionary thermals

As aerospace manufacturers seek vehicles that can fly longer, faster and farther, the heat management requirements for composites — rarely standard — will continue to climb, challenging the limits of existing formulation strategies. Suppliers, fabricators and national laboratories are showing “considerable cool in the hot zone” through adaptive material and process science. Raptor Resins’ Repecka sees a tremendous variety of high-temperature resins on the market now, including those for very small niche applications, which can be expensive. “On programs such as the F-22 and F-35,” he says, “BMIs have demonstrated success at being easy to process with superior properties in lighter parts, and that is what composites are all about.” He believes incremental improvements will continue for the foreseeable future.

Lonza’s Das sees CEs on an upward swing, pointing out that “growth of CE resins in composites is not flat, compared to BMIs, which is notable since the material is relatively recent in aerospace and military high-temperature applications.”

Henkel’s Buisson predicts, “As composites become more widely used in aerospace structure, there will be an increasing need for formulations with tailored performance and multifunctionality that also offer cost savings for the customer.”

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

Resins for the Hot Zone, Part I: Polyimides

As next-generation aerospace programs demand higher service temperatures in structural and hot section components, a variety of polyimides vie for program approval.

Read MoreAre high-temp thermosets ready to go commercial?

Developed for the U.S. military, these high-performance matrices are branching out into wider use.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More