RocTool composite demo at K 2016

In partnership with Flextronics and Arburg, the RocTool new technology combines the forming of a composite sheet and injection overmolding of thermoplastic in the same process.

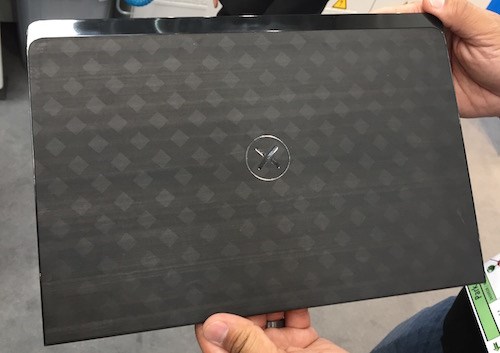

RocTool is showcasing its latest molding technologies at K 2016. The company has several demos throughout the show including one of its Induction Dual Heating (IDH) process, a combination of plastic and composite materials with the new RocTool heating configuration. In partnership with Flex and Arburg, the RocTool new technology combines the forming of a composite sheet and injection overmolding of thermoplastic in the same process. RocTool presented the process for a "hybrid" 14-inch computer cover that is 1.0 mm thick, bringing the benefits of composite (high modulus, lightweight) and plastic (cosmetic integration functions integrations) in one and the same product while eliminating secondary operations. This is done in a 1-minute cycle time per part and in the same machine. Pretty cool technology. Here's the computer cover:

Check out video of the process below:

Related Content

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.