Global market research firm Lucintel (Dallas, TX, US) predicts that the worldwide bicycle market will be worth US$59.9 billion by 2021, with CAGR of 2.4% from 2016 to 2021. Although bicycles with carbon fiber composites frames and other components will no doubt still account for a small percentage of that market’s upper end, it is clear that bicycle manufacturers are increasingly turning to carbon fiber composites for the advantages they offer. Compared to aluminum bikes, those made with carbon fiber are extremely lightweight, have greater strength and stiffness and damp vibration better due to the viscoelastic nature of resin matrices. Further, they are more responsive in terms of handling and feel, and, because they are molded, they can be made more aesthetically attractive, with striking texture choices.

All of this is very appealing to riders, says Dr. Scott W. Beckwith, president of BTG Composites Inc. (Taylorsville, UT, US) and the global technical director for the Society for the Advancement of Materials and Process Engineering (SAMPE, Diamond Bar, CA, US).

There is a caveat, of course: Composite parts and structures cannot be designed or built in the same ways used to conceive and construct amorphous metallic parts. Composite materials are typically anisotropic. That is, their strength and other mechanical properties are directional rather than uniform — the load-carrying capacity of the composite is optimal in the direction(s) of fiber orientation. This, of course, provides a great advantage to the designer, but also is a source of aggravation in that the designer must select carefully from what has become a vast array of composite material possibilities to best meet a manufacturer’s specific bike performance requirements.

Resources exist, and are also readily available. “ASTM, in particular the D30 Composite Materials Committee, has decades of test methods at their disposal for determining (a) composite material design allowables, (b) state of actual cure, and (c) verification of fiber-resin void contents,” Beckwith points out. “Yet the majority of bicycle manufacturing companies never seem to use them in their design processes.”

Beckwith cites this type of corner cutting, done by bike manufacturers to decrease costs, as the type of major mistake that can lead to part failure and accidents on the road. “The majority of bike manufacturers assume that the materials of construction and the process is forgiving because, almost always, only the outside surfaces are visually observable upon removal from the processing mold, but this is a risky assumption.”

Most defects in composite structures — in the present case, frames, front forks, handlebars and other bike components — are invisible until the part fails.

Beckwith, who also serves as an expert witness in forensic investigations involving composite failures in road-bike structures, observes, “I have not seen a stress analysis, or set of material strength allowables or an applied safety factor for any of roughly 50 carbon fiber high-performance bike failures.” That needs to change, he insists: “Manufacturing, structural analysis, quality control, testing and inspection are all important considerations in controlling a very labor-intensive molding and composites manufacturing process.”

Here then, CW, with help from Dr. Beckwith, presents some accumulated wisdom from those who have taken seriously the unique challenges presented by the design and manufacture of composite bike components. The starting point, of course, is design.

Design factors

The first major design factor is the purpose of the bike: Different uses impose different design imperatives. Pierre Legay, structural and CFD analyst for bike manufacturer Argon18 (Montreal, QC, Canada) explains, for example, that “low weight and high pedaling stiffness are required for race bikes, aerodynamics will be more critical for triathlon bikes, and good comfort will be required for endurance road bikes.”

“Its purpose defines the bike’s loads and functionality, defines environmental variables and structural performance and safety targets,” emphasizes Bertram Stier, research engineer, advanced composites, for Collier Research Corp. (Newport News, VA, US).

The geometry of the bike, mostly dictated by function and style, and the scale of the series (produced units), are also design factors that “dominate the balance between the emphasis on ease (and cost) of manufacturing and structural performance,” Stier says. “An enormous amount of data, techniques and constraints all contribute in a major way to restrict and define the design problem, which is the reason why composites optimization software can play a crucial part in design solutions.”

Design solutions

The nearly infinite material design possibilities for a composite structure, however, make traditional design approaches — even those that involve standard computer aids — time-consuming and potentially subject to failure. But there are design solutions available today that offer software platforms that can simulate and optimize fiber architecture and ply shapes that will meet bicycle OEM specifications.

Fabio Bressan, manager composite materials and virtual engineering for Solvay Composite Materials (Alpharetta, GA, US), affirms that, contending, “The best way is not to build a physical prototype but to build a computer prototype” that simulates the actual product. “Simulation is a special environment where you can increase the complexity of your imagination or the way you want to invent a new design.” He sees simulation as a bridge between materials and manufacturing — important because a composite material design is only as good as its manufacturability.

Bressan identifies four equally important goals for every commercial design. First is cost. Bressan, whose background includes Formula One and America’s Cup composite racecar and yacht designs, emphasizes that the first design goal is to consider the cost not only of the material itself, but “everything you design, the complexity you bring.”

The second priority is weight, which Bressan points out depends on the fiber direction, or fiber architecture. “Every single tube on a bicycle works differently — some working more in torsion, others more in bending and still others working more in compression, for example,” he explains. Fiber architecture can be optimized for these loads. “This is the beauty of using composite materials compared to aluminum or titanium or metals in general, because the material itself is variable.”

Third is stiffness. “Stiffness is so important because it is a matter of energy,” Bressan says. “You react fast when you need to react, you push the bicycle and all the energy that you put into the bike becomes your speed. So the stiffness becomes a priority.” A bicycle with inadequate stiffness — for example, one made using low-modulus carbon fibers — can deform as the rider pumps on the pedals and pulls up on the handlebars to climb a hill or increase speed. When the bicycle deforms, some of the rider’s energy is lost. Bressan explains, “The material absorbs that energy and instead of having energy that pushes you, and you go faster, you lose part of that energy.”

The fourth and final consideration is safety. Optimization of material and manufacturing choices to best support specified critical load and performance targets is also the road to safer operation, Bressan says. And what defines optimum for a particular bike model depends to a significant degree on our first design factor, its intended purpose or use: A mountain bike cannot be designed perilously close to the breaking point like a Tour de France racing bike, to optimize stiffness and weight savings, when it must survive impacts on protruding stones as its rider pushes up and flies down steep winding trails. Instead, its strength and flexibility must be maximized to preserve both bike and rider. Similarly, that road bike now for sale in the bike shops, styled and painted to look for all the world like the racing bike that took the winner’s cup in last year’s Big Race, must be beefed up and can’t weigh as little as its namesake if it is to survive thousands of miles of sometimes rough pavement, when that similar-looking championship bike was expected to perform in but a single race series. Further, any structural defects, especially at removable part joints, reduce stiffness and strength in the regions of the defects and affect not only performance but rider safety. Steps must be taken to prevent such defects and provide for adequate manufactured part inspection.

Design tools

Among other simulation platforms, Bressan has used HyperMesh, a HyperWorks product from Altair Engineering (Troy, MI, US). Jeffrey Wollschlager, Altair’s senior director, composites technology, explains that Altair “took topology optimization technology that was originally developed for isotropic metals and adapted it to directional composite anisotropic materials.” Its multi-scale simulation features reach down to design levels of individual fiber and resin constituents, allowing the designer to “design-tune not only the structure but also the material,” as well as offer manufacturing simulation capability that enables the user to simulate draping individual plies onto the tooling, he says.

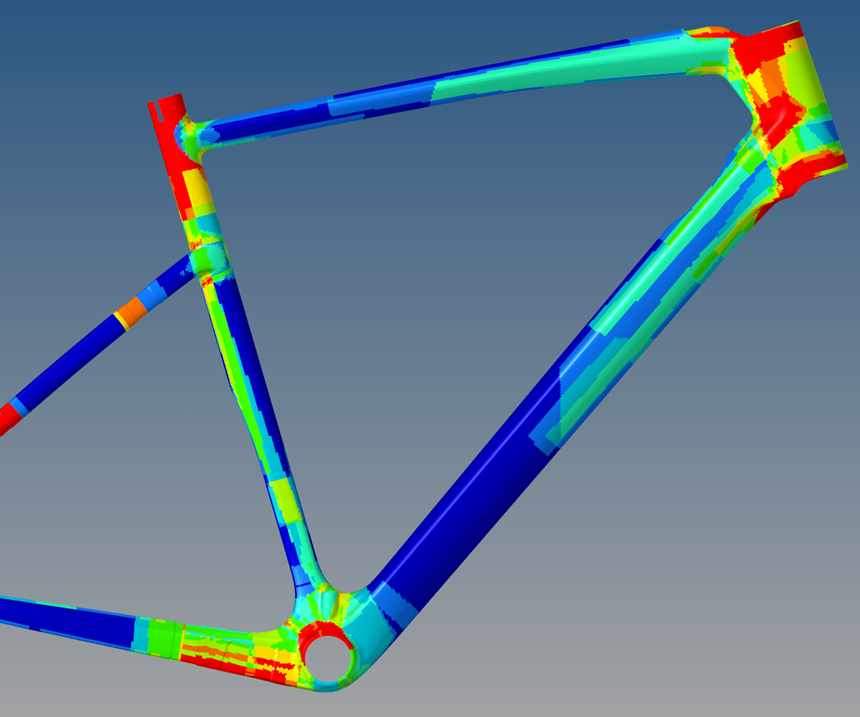

HyperWorks is used by Argon18 “to reduce cost and time during the development of a bike frame,” says Legay (Fig. 1). “It allows us to develop optimized products that we could not get by test and trial-and-error only.”

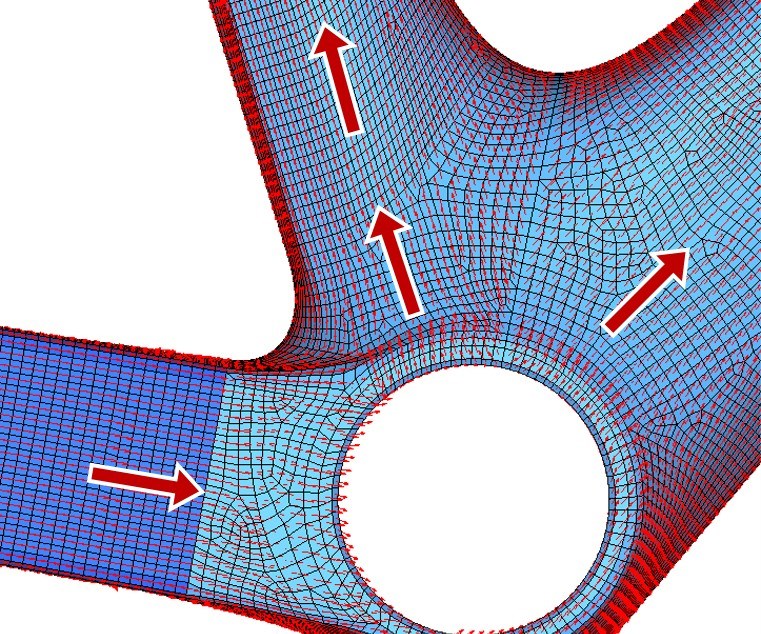

The HyperWorks platform also was successfully used by composite bike design specialist Gridlayer LLC (Denver, CO, US) in the design of the Alfa all-road bike for Allied Cycle Works/HIA-Velo (Little Rock, AR, US) (Fig. 2) “A composite bicycle must ride great and provide adequate comfort for the rider while meeting safety standards. HyperWorks allows us to optimize and verify the laminate design long before material or tooling is cut,” says Gridlayer founder and owner Chris Meertens. “Once tooling is made, you are locked in.” (Fig. 3.)

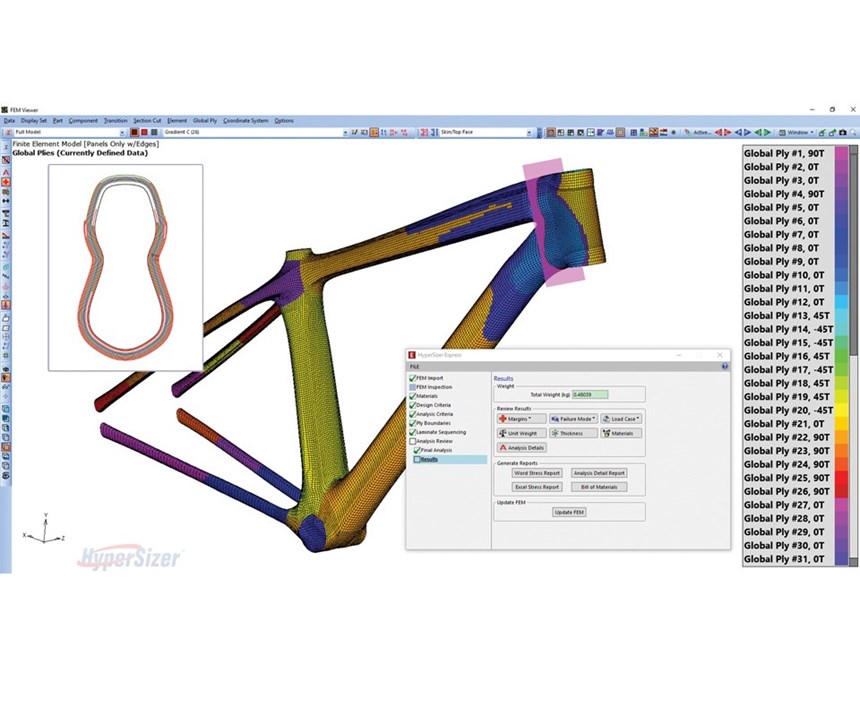

Another design software choice for composite bicycles is Collier’s HyperSizer. Computer-aided engineering (CAE) software that couples with finite element analysis to analyze and optimize structures, HyperSizer is a NASA-spinoff software originally conceived for the aerospace industry. (Fig 4.)

Material selections

These design factors and solutions guide selection of the best materials for the bike’s purpose. Materials suppliers provide the tested property values of their products, which then can be entered into design software at the constituent, raw materials level. But it’s also necessary to determine the strength of the cured part, through coupon testing, which is the next design level after individual fiber/resin constituents.

Stier says, “So far, the unchallenged frontrunner for composite high-performance bikes is unidirectional (UD) carbon fiber combined with epoxy thermosets in their various combinations.” But Stier and others point out that this combination, by itself, makes a fairly brittle composite. And that, left unmitigated, can be a safety risk. That brittleness, however, can be offset by adding thermoplastics in some form to the composite. “Their higher strain energy release rate (or toughness) might reduce the conservatism demanded from the rather brittle carbon epoxies and, thus, yield more safety due to increased fatigue- and damage-tolerance,” he suggests.

Epoxies can be “toughened” via the addition of rubber compounds. Epoxy suppliers can provide them toughened in the formulation process. But bicycle designers and manufacturers are discovering ways to incorporate the mix of thermosets and thermoplastics into their design processes. For example, Jen Hanna, director of business development for Innegra Technologies (Greenville, SC, US), says Innegra high-modulus polypropylene (HMPP) UD and woven fiber has become a thermoplastic constituent of choice for some bicycle manufacturers. When mixing thermoplastics with thermoset matrices, however, cure cycles need to be carefully considered. “We recommend processing temps below 150°C [302°F]. Innegra works very well in a 250°F [121°C] prepreg.” She adds that that would present a challenge to the bike manufacturer on a quest for quicker cure cycles, which often means higher temperatures, noting that in that scenario, “Innegra would struggle to be a fit.” But a small sacrifice in production speed can be a good trade-off for the benefits that HMPP brings to bicycle performance. “The ductile nature and excellent flex-fatigue properties allow the material to withstand impacts, reduce vibrations and limit or stop fracture propagation in composite parts,” she points out, “creating a safer cycling product.”

Thermoplastics may enable bike parts to better handle temperature swings in very hot or cold climates: “Innegra is stable on cryogenic levels down to -90°C [-130°F] and probably further,” Hanna notes. “We have tested to that degree and saw absolutely no change in mechanical properties. On the higher end, 165°F [74°C] is the melt temperature.” She quips, “I hope no one is cycling in that climate!”

TeXtreme spread-tow carbon fiber reinforcements from Oxeon AB (Borås, Sweden) also are being used to reduce weight and improve performance under load — especially to protect laminates from micro-cracking. Fredrik Ohlsson, product development director for Oxeon, explains: “By mixing and varying the layup sequence, by combining thicker materials (standard tow) and thinner materials (spread tow), it is possible to load a composite in its transverse direction to a much higher degree before cracks occur in the matrix between the filaments.” This is reportedly a great advantage in bicycles, where each push of the pedal induces a cyclic load path in multiple directions through the bike frame.

Commingling TeXtreme spread tow with Innegra’s HMPP fiber endows the part with higher elongation and ductility. “If you have a catastrophic failure of the composite part, it stays together because of the higher elongation fibers,” Ohlsson contends. “If there is a failure in a handlebar, the composite does not break completely but stays held together, minimizing the risk to hit your nose on the ground. Instead you could still maintain control of the bike until full stop.”

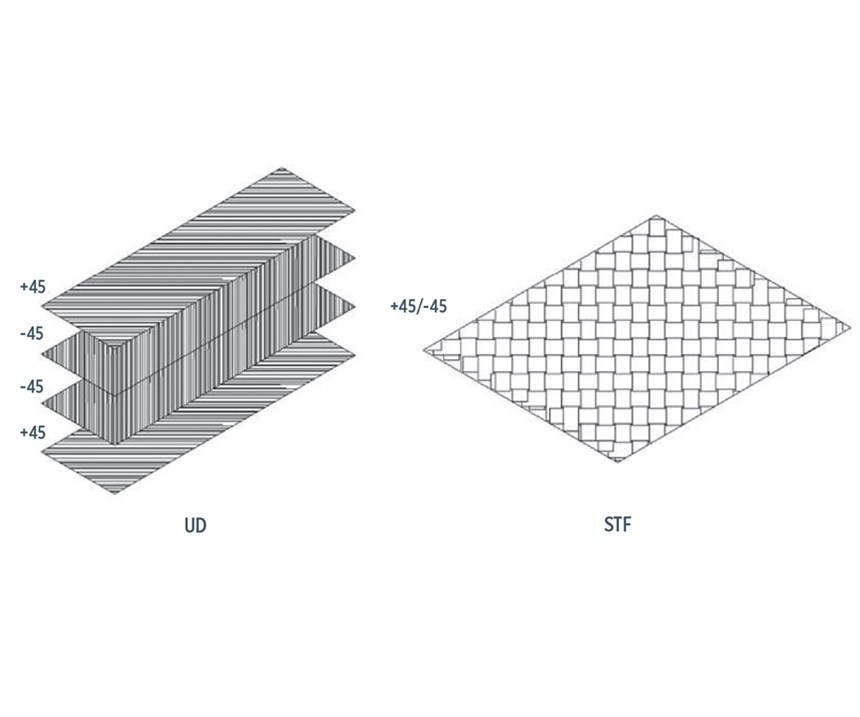

Oxeon spreads 12K (and greater) carbon tows, and reportedly can tailor biaxial or hybridized plies, or other UD or multi-directional fabric materials. The company works closely with its customers to help identify and optimize customer requirements. Ohlsson says the spread-tow fabrics also drape better than standard UD tapes around double curvatures or square shapes, yet still present the mechanical performance of cross-plied UDs. He adds, “We can tailor the fabric to change a four-ply UD layup into one fabric ply, possibly with different amounts of fiber in warp and weft, that gives exactly the requisite number of 0° and 90° fibers while still presenting a symmetrical layup.” (Fig. 5.)

TeXtreme is used by bike manufacturer Masi Bikes (Vista, CA, US) for its new frames and forks, reducing fabric weight by 100 g/m2 while improving stiffness. “The goal wasn’t to just make the frame lighter, we also wanted to make it a bit smoother without giving up any drivetrain stiffness. The material is so thin, we could work with several plies to get the same thickness or less, resulting in significant improvements,” says Masi’s product manager James Winchester.

Bike gear manufacturer PRO (Eindhoven, The Netherlands) makes its PRO Vibe handlebars with the same material. Weighing 220g, PRO Vibe carbon fiber composite handlebars are now the lightest in the PRO line up, and Innegra fibers “strengthen the bar’s most vulnerable areas without compromising its weight, so your handlebar is ready to ride in the harshest conditions,” Pro states.

Sam Pickman, director of product/engineering for Allied Cycle Works/HIA-Velo, emphasizes the advantages of selectively adjusting the ratio and composition of carbon and thermoplastic fiber content in the layup to pinpoint the desired between performance/weight/cost balance for each bike model. “For a laminate that has its eye on price,” he notes, “we use a combination of standard-modulus UD [carbon fiber] prepreg in 150-g/m2 weight, a quasi-isotropic stack from Vectorply Corp. [Phenix City, AL, US], and Innegra in key locations to add damage tolerance and toughness.”

To build a super-lightweight layup that takes advantage of thermoplastic fatigue- and damage-tolerance benefits, Pickman uses an intermediate-modulus 100-g/m2 UD prepreg with a TeXtreme/Innegra hybrid material to add toughness.

For its production Alfa all-road bike, Allied uses about 1m2 of 150-g/m2 Innegra prepreg weave in areas of the bike “that are at high risk of impact,” says Pickman. But the majority of the layup, he says, is 150-g/m2 standard-modulus UD prepreg (Mitsubishi Composite Materials Div., Irvine, CA, US). For its coming Alfa X, “we are using the 166-g/m2 TeXtreme/Innegra as the outermost ply for the entire bike, with the base layup as 110-g/m2 intermediate-modulus UD Mitsubishi fiber, both prepreg.”

Finding defects

Because part failure at the speeds and road conditions experienced in today’s cycling domain can be catastrophic for both bike and rider, nondestructive testing (NDT) of individual components and even the final bicycle can help identify and reduce defects in the manufacturing process.

However, HIA-Velo’s Pickman warns that NDT isn’t enough. “You can learn some things from NDT, but to really learn through development, we test to failure, then cut the parts up to inspect the molding quality.”

Bressan agrees. “Honestly, with the first prototype, we just destroy the part. We cut the part in sections and see what we can see inside, to be sure the technology is working properly.” Even then, he adds, there are physical limitations. Even when the part is destroyed, one may not be able to verify everything.

After an accident, Bressan recommends C-scan tomography inspection of the part. Although he acknowledges that it is a very expensive procedure, he maintains, “Tomography allows you to check each layer and see what is happening between the materials.”

“Testing final products by enveloping the structure using a little more than critical design to loads is the current methodology, at least for high-performance bikes,” Stier says. Clarifying this statement, he explains that a bike is normally designed to handle loads 1.5 or two times greater than those expected. So if the part is loaded for mechanical testing at, say, 1.3 times the design load, and it does not break, “you have proven its structural integrity, which is worth more than analysis, which could always be flawed due to the nature of assumptions,” Stier offers.

Beckwith, however, questions this method’s reliability, noting that in most cases, there is an absence of detailed structural analyses. Loading the part for mechanical testing can induce internal manufacturing voids and delaminations that may approach critical fracture levels, he points out. Further, “Static loads do not account for braking loads, which induce high frictional heat and induced loads on wheels and forks. And long-term service fatigue definitely needs to be considered, as well as vibration loads imposed over time on any composite components.”

“Sectioning [breaking] carbon fiber forks, which represent 82% of observed failures,” says Beckwith, “often clearly shows significant leading and trailing edge porosity, voids and delamination incurred during the molding process.”

Standards and regulations

Beckwith notes further that no legally binding structural safety standards yet exist that address common rider load and environmental conditions (braking, impact loads, fatigue, vibration, material aging or degradation, material abrasion and wear) for high-performance composite bikes. Further, the existing ASTM D-30 test methods are not yet recognized by ASTM’s F-08 Bicycle Committee.

That said, the International Organization for Standardization (ISO, Zurich, Switzerland) published its ISO 4210 standard for bicycles in 2014 and 2015 in nine sections. ISO 4210 was “developed in response to demand throughout the world, and the aim has been to ensure that bicycles manufactured in compliance with this International Standard will be as safe as is practically possible [editor’s italics]. The scope has been limited to safety considerations and has specifically avoided standardization of components,” according to ISO.

Bike safety won’t wait

Given the market’s growth projections, composite bicycles will certainly proliferate anywhere riders value high performance. Admired for their benefits in high-performance bikes, composites also must command careful attention from those who design and manufacture them. In time, standards and regulations will find their proper place, but this industry can’t wait. Tools for design, testing and post-production evaluation of bikes that can keep their riders satisfied and safer are available, but bicycle builders must put them to use and support ongoing development of best practices.

Related Content

Improving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreThe basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

Read MoreAurora reveals latest SPRINT X-Plane design concept

An Aurora and Boeing team advances its high-speed, vertical lift concept to the preliminary design phase, which features three lift fans, a more refined composite exterior and an uncrewed cockpit.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)