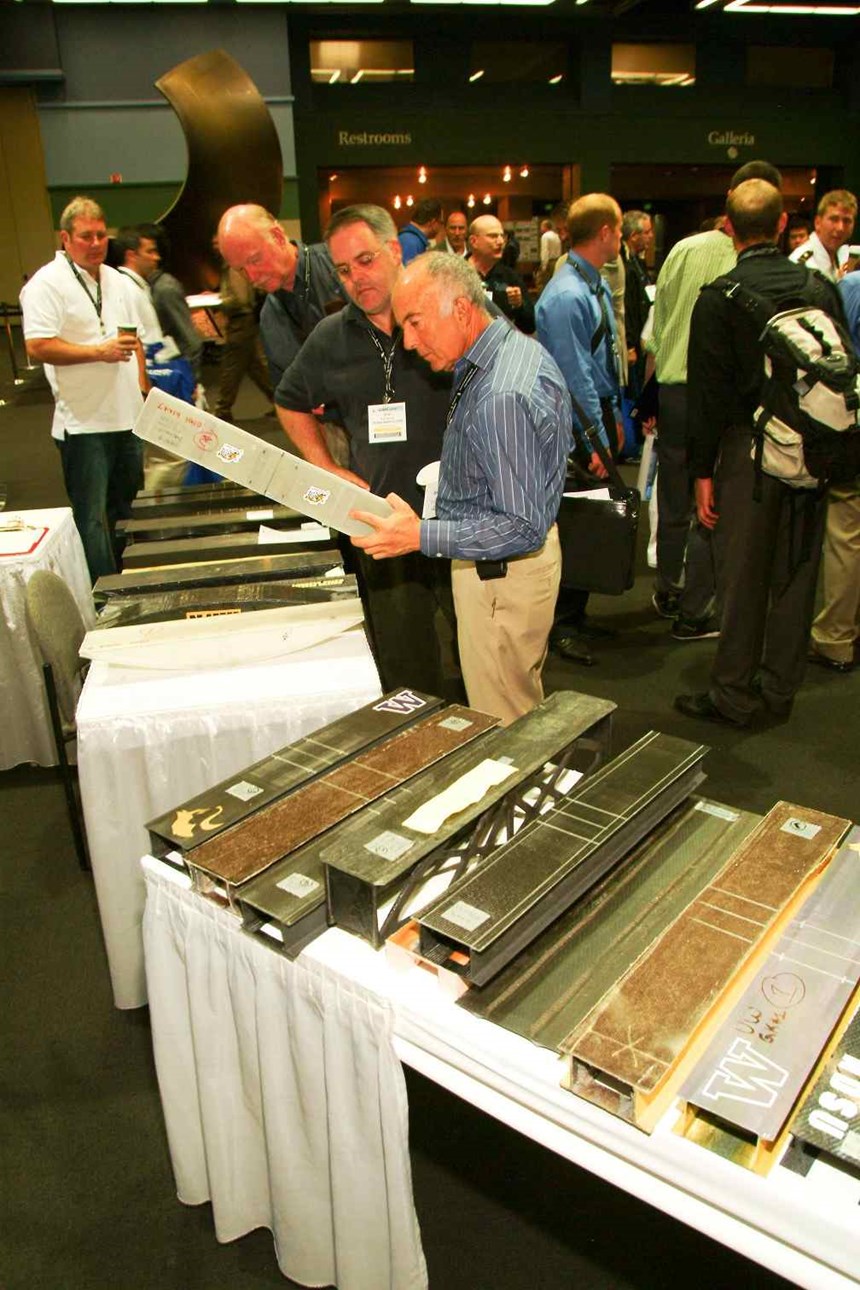

SAMPE Tech Seattle 2014 Preview

The Society for the Advancement of Material and Process Engineering’s annual fall Tech conference is now a spring event.

What: SAMPE Tech Seattle 2014 Conference

When: June 2-5 (Exhibits open June 3-4)

Where: 800 Convention Pl., Seattle, WA 98101

Although it has been for many years the fall conference follow-up to SAMPE’s (Covina, Calif.) annual Convention and Exhibition in the spring, SAMPE Tech has been moved to early June this year to make way for the debut of the Composites and Advanced Materials Expo (CAMX), the new North American exhibition cosponsored by SAMPE and the American Composites Manufacturers Assn. (Arlington, Va.). CAMX combines SAMPE’s former spring expo and ACMA’s previous turn-of-the-year COMPOSITES trade show into one big supershow that will make its inaugural appearance in Orlando, Fla., Oct. 13-16, 2014.

New season, same reason

Despite the change in timeframe, SAMPE Tech Seattle 2014 will continue a long tradition of delivering high-quality education and networking opportunities. In recent years, it has incorporated a progressively larger exhibit space devoted to showcasing advanced materials and processes for aerospace and other high-tech end-markets. SAMPE Seattle is billed as the right destination for those who use advanced composites in a variety of markets. Chief among them are aerospace (95.2 percent of visitors serve this market), wind energy (50.6 percent), ground transportation and marine (each of interest to 47 percent), sports & recreation (39.8 percent), medical (33.7) and infrastructure (19.3 percent).

SAMPE Seattle is expected to build on that pedigree. SAMPE organizers say its most recent Seattle event attracted 5,000 attendees, hailing from all 50 U.S. states and 32 other countries, worldwide. A similar crowd is expected to be on hand this year to take in hundreds of presentations by industry insiders, leaders and educators, and view the displays of some 200 exhibiting companies.

Given these statistics on attendance, the first Spring SAMPE Tech event has, appropriately, been scheduled again in one of the hotbeds of the U.S. aerospace industry. Seattle is the site, of course, for the Commercial Airplanes unit of aerospace giant, The Boeing Co., and the U.S. West Coast — from Seattle to San Diego, Calif. — is home to, or the site of significant outposts of, hundreds of advanced materials suppliers, processing equipment manufacturers and composite parts fabricators.

Tech talk: Automotive

Despite the aerospace-intensive setting, SAMPE Seattle proceedings will be capped by a Keynote Address that highlights growing advanced materials use in automobiles. Keynoter Jörg Pohlman, managing director of SGL Carbon SE (Wiesbaden, Germany), will update the continuing story of SGL Automotive Carbon Fibers (ACF), the joint venture between BMW Group and SGL Group that is the exclusive suppler of carbon fiber materials to the BMW Group, the first carmaker in the world to use carbon fiber in series production of this scale for its new i3 commuter car and i8 sports car. Pohlman will provide an overview of the entire value chain, ranging from precursor supply to the production of CFRP parts for the vehicles. The spotlight will be on carbon fiber production in Moses Lake, Wash., which operates on 100 percent renewable energy based on hydropower, as well as SGL ACF’s Wackersdorf, Germany-based fabric-weaving and newly developed carbon fiber waste recycling operations that provide materials used in i3 and i8 roof and rear seat components.

The first of four Featured Lecturers, Prof. Jan-Anders E. Månson, Ecole Polytechnique Fédérale de Lausanne (EPFL) Laboratory of Polymer and Composite Technology (LTC), will discuss the European Union’s CO2 auto emissions legislation and resulting focus on lightweight material alternatives that can be used in high-volume automotive manufacturing at a realistic cost, with realistic potential for recyclability.

Dodd Grande, VP of outdoor product development at Seattle-based snow ski and snowboard specialist K2 Sports will review the history and current uses of composites applications in sporting goods, explain why composites are ideal for them and then provide a look into the future of composites in the sports and recreation industry.

Prof. Douglas Scott Cairns of Montana State University’s Department of Mechanical and Industrial Engineering will speak about manufacturing defects and their effect on design constraints and resulting “worst-case” design assumptions. He’ll review a four-part framework for composite structure reliability, with an emphasis on progressive damage modeling that has been developed to address the issue.

Lastly, Dr. R. Byron Pipes, the John L. Bray distinguished professor of engineering at Purdue University, will propose a different approach to aircraft certification. Rather than certify parts and assemblies via physical testing, he‘ll suggest a radical departure: certification of the simulation software used for virtual testing. Certified simulation tools, he contends, would be used by engineers with the expectation that, within the bounds of the certification, no further verification or validation would be necessary. Pipes will review the significant challenges and the enormous potential savings of such an approach. (Dr. Pipes wrote Part I of a two-part series on this subject in the HPC March 2014 issue. A colleague in this effort, Rani Richardson of Dassault Systèmes (Waltham, Mass.) follows up in the May 2014 issue with Part II. (See the articles listed under "Editor's Picks," at top right.)

In addition to the above, the annual SAMPE Award Luncheon will also serve up a speaker presentation, this one from Bill Pearson, the technical director at North Sails (Milford, Conn.). He’ll review his company’s development of very thin and lightweight large-area composite membranes and structures (up to 500m2/5,382 ft2) — notably for yacht-racing sails — using articulating and reconfigurable three-dimensional molds, robotic fiber placement, and North Sails’ proprietary UD prepreg tape. He also will trace the migration of the company’s sailmaking materials into other areas of boatbuilding as well as Formula One motorsports and solar-powered aircraft applications. (HPC’s coverage of North Sails’ sailmaking methods can be viewed here.)

Preconference & conference

On Monday, June 2, SAMPE will present a daylong roster of preconference tutorials. Attendees who opt for Premium Conference Registration get tutorials at no additional charge. Otherwise, rates for the half dozen half-day tutorials are collected separately: $175 in addition to Full registration (only $75 for full-time students), and $225 for tutorial only/one-day registration/exhibits only pass.

Premium and Full Conference registrations include free exhibit hall passes (discounted conference rates are available to those who opt for early registration).

Then, June 3-5, hundreds of technical papers will be presented in 11 sessions over the three-day conference. For dates and times on SAMPE Tech Session topics and other events, see “SAMPE Seattle 2014 at a Glance,” under "Editor's Picks," at top right).

SAMPE Tech 2014 adds a new feature, dubbed a conference-within-a-conference (CWAC). Produced in response to what SAMPE officials call “high demand for reliable, up-to-date education on textiles advancements,” the CWAC will offer an extensive set of presentations on the growing variety of technical textiles available for fiber-reinforced composite structures.

The Women in SAMPE Forum is expected to offer women who work in the advanced materials field a great opportunity to network and create valuable relationships with like-minded colleagues and participate in facilitated speed-mentoring sessions.

For more information, contact Priscilla Heredia, Tel.: +1 (626) 331-0616, x610; E-mail: priscilla@sampe.org; Web site: www.sampetechseattle.org.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MorePolar Technology develops innovative solutions for hydrogen storage

Conformable “Hydrogen in a Box” prototype for compressed gas storage has been tested to 350 and 700 bar, liquid hydrogen storage is being evaluated.

Read MoreRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

Read MoreRead Next

Accelerating the certification process for aerospace composites

Columnist Byron Pipes foresees the certification of simulation software in place of physical testing.

Read MoreAn Internet aid for acceleration of aerospace composites certification

Guest columnist Rani Richardson, a CATIA composites product specialist at Dassault Systèmes (Waltham, Mass.), proposes a way to speed certification of aerospace composites.

Read More

.jpg;maxWidth=300;quality=90)