Tackling the traceability of composite materials

Have you ever looked outside an airplane window during in-flight turbulence and wondered how strong the wings really are and how much load they can take?

Share

Read Next

Have you ever looked outside an airplane window during in-flight turbulence and wondered how strong the wings really are and how much load they can take? Don’t worry, they can take at least 10 times the worst turbulence you can imagine! We know that, because in the aerospace industry, what we call traceability of materials information plays a critical role in ensuring materials auditability and, thus, their eventual qualification for safe use.

Traceability, in short, is the ability to track the trail of data generated during product development, so that one can “follow the bread crumbs” to prove the performance of, and do quality assurance verifications for, manufactured products. The traceability trail, however, might be long and very detailed. For example, to qualify a composite material, one must ensure that it meets a variety of requirements, such as strength. Many tests must be performed. Test data must be captured and linked to information about the final material and product. This link, and access to the test information, is critical so that anyone, at any point, can prove what tests were done, and then inspect the test results.

You may be thinking that ensuring this level of traceability is only important for aerospace parts, but that isn’t the case. Traceability is an increasingly important issue in the automotive industry, among energy producers and for materials suppliers as well. The ability to understand the context of your materials, and inspect those materials at any time, plays a pivotal role for auditability of design data and protection of intellectual property (IP).

Auditability becomes particularly important when multimillion-dollar decisions need to be made based on high confidence in the material properties, or when OEMs require the full proof and history that confirms that the materials meet specifications. Or when material properties are being used in simulations that ultimately will drive design decisions.

Regulatory risk. Another concern associated with traceability is the need to comply with regulations, such as the European Union’s Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), and the US Environmental Protection Agency’s (EPA) Toxic Substances Control Act (TSCA) Chemical Substance Inventory. Today, those who manufacture products that contain restricted substances, whether they are hazardous to humans, the environment or both, face potentially costly recalls, loss of consumer confidence, huge fines and even imprisonment. Traceability of materials and the substances they contain plays a crucial role in reducing that risk. It is possible to ensure that, during product development, a compliance report can be generated on both existing and new products to ensure they comply with all regulations.

Complex composites. Although, traceability is important and applicable to all materials, composite materials introduce a unique challenge to its application. They are far more complex than conventional materials, such as metals. Made up of multiple materials, reinforcements and matrices — each with its own behavior and properties — the composite system’s final properties depend on the material combination's process history, the layup, fiber orientations and part geometry. All this complexity makes it more challenging to track data, ensure its traceability and understand the effect the various input parameters will have on the final composite's behavior.

Maintaining traceability. So how do you do it for complex composite materials? First, the necessary information must be acquired within the manufacturing organization and without, from its suppliers. Unfortunately, suppliers and even internal departments often do not supply all the necessary information and underlying raw data, either for reasons of intellectual property (IP) protection or because that information does not exist. It is critical, therefore, to demand minimum information gathering.

Second, find a suitable database for information storage. Comp-osites data are complex, with anisotropic material properties represented in multidimensional ways. For a single composite system, there might be volumes of data from multiple batches of resins and reinforcements, multiple laminates and multiple test coupons that represent different tests, such as tensile, compression and shear. Managing all of this in tools such as Excel or in nonspecialized databases would prove unsustainable, long-term, for obvious reasons.

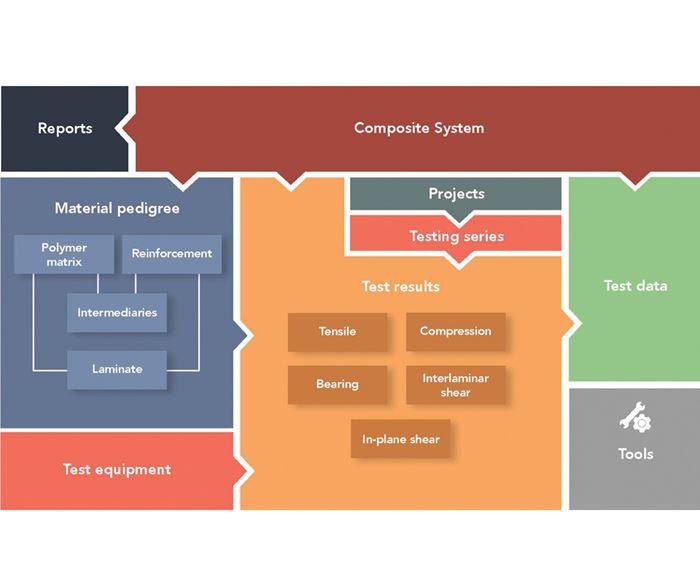

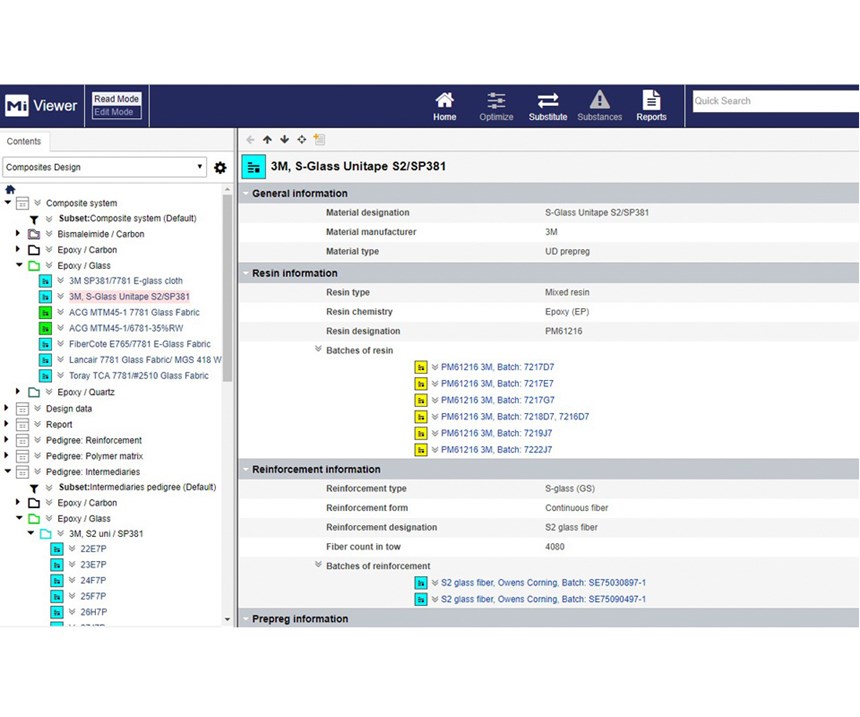

Effective management. A sustainable way is to use dedicated materials data management software that can manage the complexity and the volume of composites materials information. The most important thing to get right is the database schema — the data structure that defines what data types can be stored, and their inter-relationships. A schematic of the composites data schema developed by Granta Design, in collaboration with the members of the Material Data Management Consortium (MDMC), is shown in Fig. 1. Software tools were developed to import, analyze and manage the data — and to enable engineers to search, browse and apply it. A sample datasheet is shown in Fig. 2.

A case in point. Airbus Helicopter (Marignane, France) implemented the GRANTA MI system noted above to support its strategy for rationalizing materials sources and to ensure all details of the composites materials were captured — from materials specs and testing to design information. Its requirements were to create a single source of company materials knowledge and to create a consistent and efficient workflow for test data management. As a result of this project, Airbus Helicopters ensured critical traceability of its materials and products, risk reduction and harmonization by providing that desired single source of both material and design allowable access for its entire enterprise.

Increasingly, organizations are realizing the importance of managing materials information, maintaining traceability and making sure valuable IP is secure and shared within the company. If we can ensure that all product material properties are complete and traceable, then reassuring both the anxious airplane passenger and the sleepless compliance director will be an easy job.

Related Content

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreThermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More