The emerging commercial space industry

A decade since NASA opened extraterrestrial space to potential use as a commercial industry workplace, CW traces the role composites have played in public/private progress toward that goal.

Once the sole purview of NASA, a US federal agency established in 1958, and its counterpart in the former Soviet Union, the space beyond Earth’s atmosphere became a hot destination in the 1960s. The resulting space race consumed the public’s imagination and the scientific community’s technical ingenuity. Although the Soviets launched first (Sputnik and cosmonaut Yuri Gagarin were both firsts), the US was said to have “won” the race when NASA’s Apollo 11 touched down on the moon, July 20, 1969, and astronaut Neil Armstrong stepped out to walk on its surface.

Moving from slide rules to computers, NASA’s workforce and its contractors went on to build five Space Shuttles. Following the first launch in April 1981, they flew 135 missions. But when the aging fleet was retired after 30 years, much had changed. No longer a competitor, post-Soviet Russia had become a NASA supplier/partner. Crews — from Russia, the US and elsewhere, sometimes together on the same flight — and cargo were transported on Russia’s Soyuz and Progress spaceships, respectively, to the symbol of a new vision for cooperative space exploration, the International Space Station (ISS).

Composites in space: The commercial market

Meanwhile, a no less profound vision was incubating: In 2006, US government programs were established to stimulate a commercial space program, with NASA acting as a “financial investor without equity” and technical consultant. In short, NASA was opening its vast legacy of space technology to private industry. The resulting Commercial Crew & Cargo Program (C3PO) and the Commercial Orbital Transportation Services (COTS) program were aimed at giving the US the capability to deliver crews and cargo to the ISS again from its own soil.

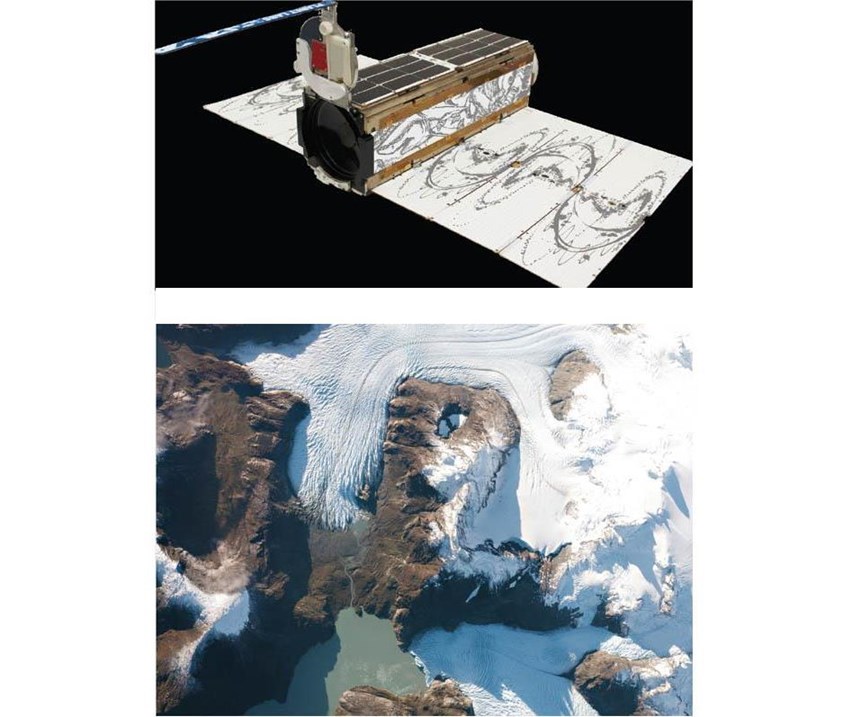

Along the way, private industry began to have ideas of its own about commercializing space. One result is that there are some 1,300 satellites in Earth orbit. Many of them perform commercial functions: Most of us rely on them for mobile phone, TV and GPS services. Others are research-related, and gather data for universities and government programs (Fig. 7, at left). Further, private companies have pursued much-publicized replacements for the Space Shuttle, future space-travel exigencies, such as Moon habitats, and even spacecraft for tourists. (See "Editor's Picks.")

Kathryn Lueders, program manager for NASA’s Commercial Crew Program (CCP), says that was precisely the point: “The first important goal ... was to be working with industry so industry could start providing the key transportation capability to the ISS,” she notes, but emphasizes, “This frees NASA resources to focus on its exploration goals. And at the same time, this enables the partnership companies to develop and market their space capabilities for commercial uses, as well.”

CCP’s second goal was to make ISS a science laboratory, and to deliver crew to the ISS to perform that scientific work. Some 15 years of ISS data is now available for research. “People will be getting their Ph.Ds off this data for many years to come,” she contends, pointing out that, ultimately, this represents a substantial return on investment for the nation.

A third goal was to reap the benefits of competition: Lueders notes that when multiple companies try to solve the same problems, unique solutions are found. Significant advances have come about in material science and manufacturing as new designs are evolved. “We are all learning about the best materials for the thermal protection systems that will most safely protect the crew and the cargo in the launch environment, in operation in space and on the return through Earth’s atmosphere,” she says.

As private industry has begun to explore the commercial potential in space flight, the high strength- and stiffness-to-weight, thermal stability in wildly varying temperatures and exceptional producibility for large, complex shapes of composites have been an enabling technology for space excursions. Given the breadth and variety of current space-related composites applications, this CW overview is by no means an exhaustive study of their use in the commercial space industry. The small and large manufacturing companies that make today’s composites-intensive spacecraft and other off-Earth products are simply too numerous to list, let alone credit for their work (but see the articles under "Editor's Picks"). At best it’s a series of snapshots — of prominent features and participants.

Cargo Resupply Services (CRS)

As part of its COTS program, the first partnership NASA opened to private industry was for Commercial Resupply Services (CRS). The goal was a US vehicle to transport to and from ISS both cargo and supplies, ranging from food, water, clothing and personal items for the crew to components necessary for science experiments. The first contracts under CRS-1 were awarded to Space Exploration Technologies’ (SpaceX, Hawthorne, CA, US) and Orbital ATK (Dulles, VA, US) in December 2008, and “CRS-1 will remain active through 2018,” says Daniel Huot, a public relations officer for Johnson Space Center (Houston, TX, US).

In August 2012, the SpaceX cargo ship Dragon became the first commercial spacecraft to dock on the ISS (see Learn More). Although the Dragon capsule is not reusable, it can re-enter Earth’s atmosphere and make a water landing via parachute (in this case, about 250 miles off the coast of southern California, in the Pacific Ocean), and, thus, can return cargo to Earth, including material resulting from ISS science experiments. Although it is known that SpaceX does use composite materials for some parts of Dragon, the company did not respond to requests for information for this article.

Orbital ATK (Dulles, VA, US) fulfills its CRS-1 contract with its Cygnus spacecraft. Orbital’s long history in space began with the world’s first privately developed launch vehicle more than 25 years ago, says Orbital’s Sean Wilson, director of corporate communications. Its spacecraft are in low Earth orbit (LEO), geosynchronous orbit and in deep space. Its Antares launch vehicle supports commercial and government payloads. The company is now working on — and fully self-funding — a Mission Extension Vehicle, designed for servicing satellites in orbit. The first test article is slated for launch in late 2018.

Orbital houses the spacecraft’s avionics, electrical propulsion and communications systems in its Cygnus service module, which is a 12-sided structure with circular forward and aft decks. Each of the 12 panels and aft deck are aluminum honeycomb sandwich panels. Carbon composite skins are on the aft deck structure, but the 12 equipment panels have aluminum skins.

Carbon composite sandwich structures with composite skins and aluminum honeycomb core are also used to make up the main structure for Orbital’s rigid solar arrays. The facesheets are first autoclave-precured, then are co-cured in an autoclave with various inserts and the core material. Other structural inserts are cold-bonded into the panel afterwards. The cured parts are then machined to final dimensions. “To be a substrate for solar cells, the electrically conductive carbon fiber is covered by an insulting material on the side to which the solar cells are bonded,” Wilson explains.

SpaceX and Orbital now regularly resupply the ISS. At this writing, SpaceX had completed eight and Orbital five missions. In May 2016, ISS hosted Dragon and Cygnus at the same time. “There is room for six vehicles to be docked simultaneously,” Huot explains. “And along with those two US vehicles, two Russian Soyuz and two Russian Progress ships were also moored at the station.”

In January 2016, NASA awarded a CRS-2 contract to Sierra Nevada Corp. Space Systems (SNC, Louisville, CO, US). Resupply via its Dream Chaser SpaceSystem (DCSS) is scheduled for 2019- 2024, with earliest launch expected in late 2019.

Like the previous Space Shuttles, DCSS launches vertically, lands horizontally (VTHL) and is reusable. It has been modified for uncrewed cargo missions to meet CRS-2 requirements. The crew version has fixed wings and launches vertically on top of the launch vehicle without a fairing encasing the vehicle — a feature allowing a mission to be aborted during launch if necessary for crew safety. The uncrewed cargo spacecraft does not need this capability, so its wings fold, allowing it to be mounted in a standard 5m-diameter payload fairing. Its main propulsion system, originally included for abort capability, has been removed to make space for more cargo storage. Further, a separate cargo module has been added as well.

Dream Chaser’s primary and secondary structures, including aerosurfaces and aeroshells, canted fins, cabin and bulkhead, are constructed from carbon fiber prepregged with bismaleimide (BMI) resin, in woven fabric and unidirectional tape, in a sandwich structure with a nonmetallic honeycomb core. The latest design employs extensive co-bonding in an autoclave, incorporating advanced 3D woven preform joints.

SNC’s space technologies group already provides critical subsystems to NASA and to other commercial space companies throughout the world. “We have provided thousands of components, supporting over 450 space missions, including more than 70 NASA missions that have gone to seven planets in our solar system, and in the last two years have also launched 18 satellites,” says John Roth, VP of business development for SNC’s Space Systems. “I would say our overall vision is to continue to be an integral part of humanity’s use, and exploration, of space.”

Commercial Crew Program (CCP)

Established in 2010, NASA’s Commercial Crew Program (CCP) selected SpaceX and The Boeing Co. (Chicago, IL, US) to design and build human-rated spacecraft to transport crew and cargo to the ISS. SpaceX is modifying its Dragon to meet NASA’s CCP requirements and Boeing is in the process of building its Crew Space Transportation (CST-100) Starliner.

The test article of Boeing’s Starliner capsule is undergoing thorough testing at Boeing’s Huntington Beach, CA, US, facility. In Boeing’s terms, it is being “shaked, baked and tested to the extreme.” A second Starliner, called Spacecraft 1, is being assembled at NASA Kennedy in Florida. The upper and lower domes of the pressurized spacecraft are aluminum, made in a weldless spinforming process and machined into a honeycomb pattern to reduce weight. Some portions of the Starliner are apparently composite, but Rebecca Regan of Boeing Communications, advises, “Because of the highly competitive environment we’re in with the Commercial Crew Program, we’re not talking about our composite parts, materials or processes at this time.”

Sierra Nevada and Blue Origin (Kent, WA, US) are potential contenders for future CCP contracts. Founded by Jeff Bezos, Blue Origin is a privately funded aerospace manufacturing and spaceflight services company. Its New Shepard six-seat crew capsule and second stage booster rocket — named for Astronaut Alan Shepard, the first American in space — are designed for vertical takeoff and vertical landing (VTVL). The crew capsule returns via multiple parachutes for landing, and the first stage booster rocket also returns to Earth. Both are reusable. The first test flight was in April 2015. In a November 2015 flight, the capsule reached an elevation of 100,534m, and both capsule and rocket were returned safely to Earth. In January 2016, the same capsule and rocket were relaunched. The capsule reached an altitude greater than 101,500m, and again, capsule and rocket safely returned and were still fit for reuse. (The Kármán line, which is 100 km/62 miles above sea level, is considered the starting point of “outer space” above Earth’s atmosphere.)

Although Blue Origin declined to discuss the materials used in the New Shepard craft, Bezos revealed in-progress plans to build a 750,000 ft2 orbital vehicle manufacturing facility at Exploration Park (Kennedy Space Center, Cape Canaveral, FL, US) “clearing the way for the production of a reusable fleet of orbital vehicles that we will launch and land, again and again.” Work on all but New Shepard’s engines is slated for the facility, which the company says will house automated composites processing equipment, clearly implying composites for its spacecraft.

Launch vehicles: To ISS and beyond

Design and assembly of launch vehicles also has been opened to private industry. SpaceX’s Falcon 9 launch vehicle pushes cargo and will ferry future crew vehicles to the ISS and other LEO missions. For its part, Orbital ATK has, thus far, used its Antares rocket to power its Cygnus on cargo delivery missions to ISS. The second stage of Antares features a solid rocket motor with a composite case, and all its upper stack structures — interstage, motor cone and payload fairing — are composite structures as well.

Headquartered in Centennial, CO, US, United Launch Alliance (ULA), a 50/50 joint venture between Boeing and Lockheed Martin (El Segundo, CA, US), is currently launching LEO missions via the ATLAS V, a version of the ATLAS rocket that served NASA so well during the 1960s race to the moon. Boeing, Sierra Nevada and Orbital all plan to launch their upcoming crewed cargo missions on ATLAS V vehicles.

The company’s Delta and ATLAS families of launch vehicles will be replaced, in time, with its next generation Vulcan launch system, the first of which will be the Centaur, scheduled to fly in 2019. A replacement, the Vulcan Aces (Advanced Cryogenic Evolved Stage), is scheduled to fly in 2023. Cryogenic refers to the propellant, which for the Aces stage will be liquid oxygen and liquid hydrogen.

The primary structure of Vulcan makes extensive use of composites. Five major carbon fiber/epoxy composite structures will make it up: The payload fairing (5.4m diameter) is available in three lengths, 20.7m, 23.5m and 26.5m. The interstage structure (5.4m diameter) is 4.1m long. This single, tapered 360° hollow piece connects the rocket’s first and second stages. It’s 5.4m in diameter at its base, and it tapers toward its upward end to interface with the smaller-diameter second stage. A 5.4m-diameter heat shield at the rocket’s base also will be a one-piece composite structure. Most of these structures also will have composite insulation protection on their exteriors. Mark Peller, VP of engineering, says ULA has completed its preliminary design review, is working on the detailed design and already has released some orders to suppliers or to the factory floor for building rocket components. “We are partnering with Ruag Space (Zurich, Switzerland; renamed to Beyond Gravity) for development and production of our composite structures,” Peller says. Ruag has supplied large composite structures to ULA, as well as major European aerospace companies, for many years and will have over-sight responsibility for the five major Vulcan composite structures — each of which will be built in one piece, using out of autoclave (OOA) materials, in ULA’s Alabama factory. This means the Vulcan will be “more efficient, lighter and, hopefully, lower cost and higher quality,” Peller says.

For the 5.4m diameter payload fairing, Ruag is using Toray T300 carbon fiber woven in either a carbon or carbon/glass (E- glass and S-glass fibers) prepreg. Ruag selected the (unidentified) resin from among various commercial resin systems, choosing the one best suited to its vacuum bag out-of-autoclave process, “recently implemented as a baseline process for all our products,” says Matteo Rendina, manager of product engineering for Ruag Space.

The payload fairing is a sandwich structure with prepreg laminate skins and an aluminum honeycomb core. A cork thermal protection system is applied to the exterior. The cylindrical-shaped main section of the fairing is laid up in 0/90° and ±45° fiber architecture on a flat table via an automated process. When complete, the layup is transferred onto a male bonding mold by a dedicated jig. The inner skin of the ogive-shaped section at the top of the fairing is hand laid directly on the final bonding mold; the outer skin is laid up on a dummy mold and then transferred to the bonding mold, and finally draped over the honey- comb core.

A co-curing process is used to manufacture a full fairing half in one piece, including the inner and outer skins, honeycomb core and thermal protection, a manufacturing process that reduces the production time and costs, Rendina says. (The payload fairing must be made in two halves, in length, because it separates during launch.) Rendina declined to disclose any details of the proprietary curing process. He says, however, that the cure profile has been fully validated by Ruag.

All composite elements are manufactured using to the same materials and process, Rendina says, although the design details vary on the different products in terms of the laminate layup, honeycomb and thermal protection system.

Space tourism

Although Virgin Galactic (Mojave, CA, US), founded by Sir Richard Branson and abetted by aerospace composites boundary-pusher Burt Rutan, has yet to realize its much publicized space tourism enterprise, its newest rocket-powered SpaceShipTwo (SS2), the VSS Unity, is in the ground-test phase, after which it will undergo extensive flight testing. Flight tests will begin with captive-carry flights attached to the WhiteKnightTwo (WW2) “mothership” followed by glide flights before proceeding with rocket-launched flights of increasing length. The latest version of WW2, the VMS Eve, is in routine service as a trainer aircraft. In service, the company expects that a WW2 will ferry a fleet of ticketed-passenger-filled SS2s aloft, then launch them for rocket-powered flight beyond 100 km/62 miles above sea level for a short, weightless sub-orbital excursion to the Kármán line. Passengers will be returned to Earth via winged flight to a landing strip (see Learn More).

Both of these space access systems have all-composite airframes. William Pomerantz, Virgin Galactic’s VP, special projects, notes that composite materials were selected largely because of their highly desirable strength-to-weight ratio, as well as their manufacturability and customization. Details of the materials and process technology are proprietary, but Pomerantz says hand layup and winding techniques are used, and parts are produced by auto- clave and out-of-autoclave processes.

LauncherOne, the company’s all-composite satellite launch vehicle, is now in construction and testing, and represents Virgin Galactic’s commercial aspirations in the small LEO satellites realm. It will be built by Virgin’s sister group, The Spaceship Co., at its design and manufacturing facility in Long Beach, CA.

NASA’s quest: Humans to Mars

The burgeoning commercial space industry has, indeed, freed NASA to focus on the demanding and radical challenges of accessing and exploring deep space. NASA is building its Orion capsule as its space vehicle to take astronauts deep into space — even eventually to Mars — with Lockheed Martin as its prime contractor. Orion’s original metal atmospheric-re-entry heat shield has been exchanged for one designed with composites, and in a parallel program, an all-composite Orion capsule has been prototyped alongside the currently mainstreamed metallic version (see Learn More). NASA also is building a new Space Launch System (SLS) for missions beyond LEO. Although Boeing is its prime contractor, opportunities are also in the works for partnering with SpaceX for launches beyond LEO.

NASA has contracted with SNC, for example, to provide critical hardware for a planned 2020 mission to Mars. It will be the 13th NASA mission to that planet for which SNC has earned a contract. On one of them, SNC provided no less than the descent braking system that lowered the Curiosity rover to the Martian surface.

Orbital ATK also has been selected by NASA, in this case, to study the concept of a cislunar habitat (cislunar refers to the space lying between the Earth and the Moon, or to the Moon’s orbit), with an eye on an eventual human mission to Mars. Orbital’s Cygnus spacecraft is a strong candidate to be used as a habitat building block for these ventures, says Orbital’s director of corporate communications Sean Wilson.

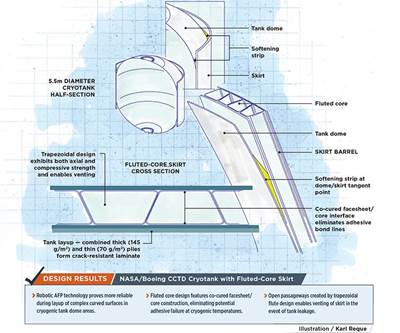

In addition, an important technology demonstration effort at NASA Marshall Space Flight Center (Huntsville, AL, US) is the development of a composite cryotank capable of containing liquid hydrogen or liquid oxygen rocket fuel (see Learn More). Completed in 2014 by a NASA/Boeing team, it marked a major accomplishment in NASA’s Game Changing Development program under the Space Technology Mission Directorate.

John Vickers, NASA principal technologist for advanced manufacturing on the composite cryotank technologies demonstration effort explains, “It was not developed for a specific launch vehicle, but as a technology demonstrator to help us increase our capability for the mission to Mars.” It would be applicable to all kinds and sizes of launch vehicles, as well as to habitats, landers, to surface vehicles — any of the logistical craft that might be needed for the mission to Mars.

About a 30% advantage is gained, in general, when composites replace metals on spacecraft. But, “when we think about the launch vehicle, it’s probably 60% of the total weight of the launch vehicle,” says Vickers, because the vast majority of the weight is made up of the fuel tanks.

Composites in space: Increasing mission capabilities

Vickers describes the challenge ahead in terms of launch vehicle-to-payload ratio, a comparison of the weight of the fuel and rocket compared to that of the payload the rocket is able to deliver to target. “If we are talking about going to LEO,” he points out, “that would be about 20:1. That is, it would take about 20 lb of fuel and rocket to deliver 1 lb of payload to LEO.” For the trip to Mars, however, the ratio, he points out, “is certainly greater than 600:1.” There’s a huge incentive, then, for NASA and private industry alike, to close that ratio to the greatest extent possible, and Vickers contends that composites offer the best opportunity available today. Whatever goes to deep space — cryo-tanks, launch vehicles, crew capsules, landers, surface vehicles — needs to have the lowest possible mass. “Typical advanced composites can reduce the weight for us by about 30%,” Vickers notes. “That’s pretty significant. But what we are really pushing for today is to reduce the weight by 50%.”

So,” he sums up, “we are seeking half the weight and half the cost at twice the speed.”

Related Content

On the radar: Reusable launch vehicles, hypersonics make space more accessible

CFRP has become key to targeting efforts in reusing components like rocket stages, as well as the development of reusable hypersonic testbeds and spaceplanes, for increasing space commercialization.

Read MoreAirborne delivers composite upper stage tank for EU ENVOL project

Nine-member consortium targets development of low-cost, green vertical orbital launcher with manufacture of an ultra-lightweight composite tank design in an automated manufacturing environment.

Read MoreHyImpulse, Adamant Composites linerless CFRP tank passes hydrostatic burst test

The liquid oxygen (LOX) tank, to be used in a HyImpulse smallsat launch vehicle, demonstrates the ability to withstand pressures well beyond the limits of its intended use.

Read MoreNanomaterials optimize performance of space-ready carbon fiber composite panels

A recent ESA project led by Adamant Composites aimed to mature nanomaterial-enhanced CFRP for lighter weight, more thermally and electrically conductive materials for manufacturing satellite structures.

Read MoreRead Next

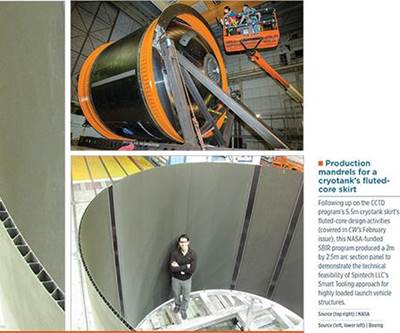

“Smart tooling” cuts time and risk for complex unitized composite structures production

One-piece bladder tooling helps to actualize NASA/Boeing’s revolutionary fluted core design for next-gen cryogenic fuel tank skirt.

Read MoreNASA/Boeing composite launch vehicle fuel tank scores firsts

Subscale 5.5m-diameter cryogenic tank demonstrator with innovative fluted-core skirt is formed via robotic AFP and cured out of the autoclave.

Read MoreNASA considers carbon nanotube mirrors for cubesat telescope

The carbon nanotube/epoxy combination is being evaluated for the fabrication of mirrors on cubesats for planetary space exploration and Earth observations.

Read More