Yachtbuilding Composites: Rigged for Success

Carbon composite cabling in several forms races ahead of dry fibers and stainless steel in sailboat rigging.

The sailing world is already a strong market for composites. Hulls, decks, masts — even steering wheels, tillers and boarding systems (see “Carbon stairs make boarding a sailing yacht a breeze" under "Editor's Picks" at top right) — are now constructed of glass, aramid and carbon fiber-reinforced polymers. But a growing portion of that market, today, is standing rigging, the relatively rigid cables that stabilize sailboat masts and, to a lesser degree, running rigging, the more flexible cables used to move and control the sails. Carbon fiber’s light weight, strength and stiffness, combined with its environmental resistance and durability, contributes to superior performance in cables, compared with the dry fiber cables and stainless steel cables used in conventional rigging systems. Carbon fiber composite sailboat rigging, today, typically relies on standard, intermediate-modulus carbon fibers, such as Toray Industries’ (Tokyo, Japan) T700 standard tensile modulus (230 GPa) and T800 intermediate tensile modulus (294 GPa) — although standing rigging is trending toward higher-modulus fibers in the range of 324 GPa.

First carbon rigging: Bundled pultruded rods

Carbon composite has become the standard rigging material for high-performance offshore race boats and superyachts, says Rob Sjostedt, partner and CEO of VectorSum (Irvine, CA, US). An avid sailor and a composites specialist, Sjostedt is generally credited as the person who brought carbon fiber to the rigging world. “My goal, 13 years ago, was to make standing rigging out of something other than heavy stainless steel rod and corrosion-susceptible wire rope.” He came up with the idea of bundling very small-diameter pultruded carbon-fiber composite rods, combined with a conical end-fitting.

This idea led, ultimately, to the successful carbon composite rigging developed and now produced under the registered trademark ECsix by Composite Rigging (North Kingstown, RI, US), part of the Southern Spars Group (Auckland, New Zealand), owned, in turn, by the North Technologies Group (Milford, CT, US).

Scott Vogel, president of Composite Rigging, says ECsix cable has been installed on more than 500 yachts, ranging from 3.4m Moths to Volvo 70s and 61m-and-longer superyachts (see Fig. 1, at left). It’s also undergone millions of loading and unloading cycles. “In just 10 years, ECsix has sailed over 1 million nautical miles in all conditions,” he claims, “and has not had a single failure due to age, wear, waves, weather or water.” Sjostedt adds that there also has never been an ECsix end-fitting failure (Fig. 2). “The bundle of small rods has proven to be very damage-resistant and can handle compression buckling on the leeward side of the mast,” he claims.

ECsix comprises a bundle of 1-mm rods, which are pultruded by Air Logistics Corporation (Monrovia, CA, US), using Toray’s T800 carbon fiber in an epoxy resin matrix. “We receive the rods on a spool,” explains Tony Reaper, sales manager for Composite Rigging. “We cut them to the required length and then bundle the correct quantity of rods for the specified rigging, terminate the bundle in titanium end-fittings and install interface hardware, such as eyes, jaws and turnbuckles.” The bundle is then pulled through a braiding machine to encase it within a protective fibrous jacket. The company has used all types of yarn for the jacket, including aramid and ultra-high molecular weight polyethylene (UHMWPE); these tough, high-performing fibers are used when rigging will be subject to significant abrasion, such as when it is used as headstays and running backstays.

Reaper believes carbon composites are virtually indispensable in high-performance racing yachts and the so-called superyachts, which are, as they say, “too big to fail.” “Superyachts have gotten so big that the naval architecture doesn’t work out unless a lightweight mast/rigging package is specified,” he explains. The key to tall-masted yacht stability is concentrating weight low in the water. “Most of these boats, today, actually must have some sort of composite standing rigging, rather than steel, to maintain the center of gravity.”

Rigid and flexible carbon rigging

Southern Spars recently acquired another leading provider, Future Fibres Rigging Systems. Started in the UK in 1997, Future Fibres moved to New Zealand for the 31st America’s Cup in 2002-2003, and then to Valencia, Spain, for the 32nd race in 2007. It’s unknown how the acquisition will affect Future Fibre’s future production but, for now, the company makes two carbon fiber rigging products, one rigid and the other flexible.

Its Thermoset Carbon (TSC) rigging (the rigid system) is designed for use as standing rigging. It’s made by looping a single continuous epoxy prepreg tow around two titanium end-terminations mounted apart from one another at a fixed distance equal to the specified cable length — a system Future Fibres notes was pioneered in 1996 by company founder Tom Hutchinson. The carbon fiber is HexTow IM9, from Hexcel (Stamford, CT, US), with a 303 GPa tensile modulus, slightly higher than that of Toray’s T800. The looped cable is loaded under tension, shrink-taped to consolidate the layup, and then cured in an oven ramped up at intervals to 180°C for two to four hours. TSC cables terminate in a small end-diameter, which helps to reduce windage, that is, the frictional force created by air on an object. The end size depends on the application; for a high-performance racing design, such as a Grand Prix Transpac 52-class (TP52) yacht, the first cable (running from the deck to the first spreader on the mast) would be about 9.3 mm in diameter. Its breaking strength would be approximately 13,400 kg.

The high-modulus fiber offers good protection against ultraviolet (UV) light, so Future Fibres says the resulting TSC generally does not need a braided protective layer; the cured cable is more often sanded and then finished with a wax or a clearcoat of varnish.

TSC typically has been used for standing rigging in high-performance boats (see Fig. 3) but the company also manufactures a flexible version, FlexC, made by the method and using the same carbon fiber, but with a different, proprietary resin for the prepreg that lends the cable flexibility. It can be used for either standing rigging or running rigging, and reportedly is most suitable for a boat that is rigged out every year.

Seamless carbon rigging

Also at the forefront of carbon composite rigging innovation is Hall Spars and Rigging (Bristol, RI, US). Opened in 1980, its history began, says owner and CEO Eric Hall, with stainless steel cable for rigging, made using swaging machines. In the late 1990s, the company tested the bundled pultruded rods produced by Air Logistics for a brief period before Southern Spars took over the technology in an exclusive contract. Hall also considered other forms of pultrusion (“fantastically expensive tooling”) as well as dry carbon (“it pulls itself apart”), and a carbon/thermoplastic prepreg. Then, after three years of development, Hall introduced, in 2008, its own unique system for making carbon composite masts, booms, spars and standing rigging called Seamless Carbon Rigging (SCR).

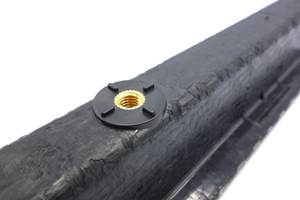

SCR is a solid carbon composite cable made using epoxy prepreg tows with intermediate-modulus carbon fiber from Mitsubishi Chemical Carbon Fiber & Composites Inc. (Composite Materials Div., Irvine, CA, US). Hall makes the SCR by “a form of filament winding,” using a machine that continuously winds the tow around end-pins, creating a loop, or sling (see Fig. 4a & b). When the winding is complete, the sling ends are pulled into conical end-fittings, and a wedge is inserted inside the loop, then pulled back into the fitting, mechanically securing the part. It is then consolidated with shrink-wrap and oven-cured. Hall uses only titanium end-fittings to avoid electrolytic reactions between carbon and aluminum or stainless steel.

Hall compares a solid SCR rod with the equivalent Nitronic 50 stainless-steel rod it replaces: “Comparing rods with a nominal breaking strength of 41,270 kg, the SCR rod has an almost identical diameter — 19.9-mm diameter compared with 19.5-mm diameter for the stainless steel rod — at about one-sixth the weight.”

Because SCR is without the spaces between rods typical of bundled pultruded-rod systems used by some competitors, Hall notes it has a smaller frontal area subject to less windage.

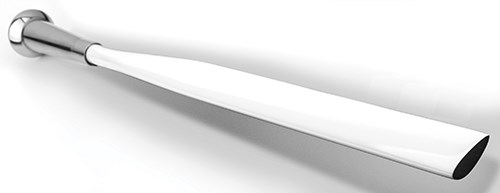

Although standard SCR is round, Hall Spars also produces a low-drag airfoil configuration for high-performance applications. Its more aerodynamic shape means even less windage (see Fig. 5a & B). Thus, “it’s a good product for cruising-boat applications, as well, because it’s quieter,” he adds. “All rigging vibrates, and the smaller the boat, the higher the vibration.”

SmartRigging BV (Joure, The Netherlands) was founded in 2004 for manufacture of composite yacht rigging. The company produces only standing rigging, a carbon composite cable called C-Evo, for yachts from 11m to 64m long. SmartRigging sales director Constantijn Weber says the C-Evo incorporates, variously, Toray T800, T1000G (294 GPa/42.7 Msi tensile modulus) or Tenax-E-IMS65 (290 GPa/42.1 Msi) from Toho Tenax America Inc. (Wuppertal, Germany), or even higher modulus fibers in an epoxy towpreg. The cables are made by SmartRigging’s endless winding system, a fully automated, computer-controlled production process. “All fibers are laid parallel in endless loops,” says Wilco van Zonneveld, business development manager for FibreMax, SmartRigging’s 2009 spin-off subsidiary, with which it shares technology and production staff to produce cables for industrial applications (e.g., heavy-lift cranes and bridge cables). “The tension on individual fibers is kept constant and equal with an accuracy of 0.1%,” says van Zonneveld, adding that end terminations can range from 2-300 mm or more, depending on the cable’s required breaking strength.

CF/thermoplastic rigging

Navtec Rigging Solutions (Guildford, CT, US) has been a leading producer of sailboat rigging since 1970, when Ken King formed the company in West Concord, MA, US, for the purpose of improving stainless-steel rod rigging technology. Today, in addition to rod rigging and dry fiber rigging, Navtec produces Thermo Fused Carbon (TFC) rigging, introduced in 2011. Like others, TFC cable is pultruded as small-diameter rods. But it is different in that 310 GPa tensile-modulus HexTow IM8 carbon fiber from Hexcel is preimpregnated with a proprietary thermoplastic matrix. Navtec bundles the pultruded carbon fiber/thermoplastic rods together, in the size and number necessary to meet rigging specifications, and then loads them evenly across the bundle. Using a Navtec-patented process that entails very high temperatures and precision-machined steel, the company fuses the strands at the cable ends into a solid bar and then reforms the existing solid bar into a head that mates with the specified end-fitting (see Fig. 6).

The thermoplastic matrix allows Navtec to mold the same composite material that forms the midspan structural rigging into a configuration that physically interlocks into the titanium end-fitting, providing compact terminations that reduce both weight and windage. The thermoplastic also makes the cable more flexible in mid-span, so it can be coiled for shipping.

Mike Curtin, Navtec engineering manager, says TFC rigging can be used for standing rigging, although “TFC does not handle a very small bend radius as well as Kevlar and PBO,” he says. It can be used in some running rigging applications, depending on the bending that will be experienced.

The consensus among rigging manufacturers is that carbon fiber composites are the future for their high-end market. But the big question is: When will they penetrate the much wider small racing yacht and recreational sailboat sectors? Here, performance can’t trump price, so carbon fiber’s high cost keeps it out of reach. For now. Carbon fiber manufacturers are working avidly to change the price equation, particularly in automotive and industrial applications. It’s possible the sailing world will benefit as well.

Related Content

PulFlex introduces pultruded Flex Connect

Fiberglass T-slot, primarily used for automation, framing and other quick setup systems, competes with aluminum alternatives.

Read MoreNovel processes for hybrid thermoset-thermoplastic pultruded parts

CFRP pultrusion and pullwinding specialist Epsilon Composite combines thermoplastic overmolding with traditional thermoset processes, demonstrated through aircraft struts and industrial applications.

Read MoreCreative Composites Group introduces H-5 rated FRP bridge decking

High-strength pultruded SuperDeck Lite gives ambulances and maintenance vehicles access to trails, bridges, boardwalks and sidewalks

Read MoreRobotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Read MoreRead Next

Carbon stairs make boarding a sailing yacht a breeze

GMT Composites (Bristol, R.I.) makes lightweight but strong — typically carbon fiber — yacht-boarding systems that are easily moved and stowed.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More