Automotive OEMs and Tier 1s are grappling with the need to reduce vehicle mass to meet fuel economy and carbon emission targets. Composite materials have the potential to contribute significantly to this lightweighting push in many areas, but cost, design issues, unfamiliar processing and competition from other materials continue to present obstacles. To overcome these, many projects are investigating how composites can be integrated into multi-material automotive structures for maximum benefit.

One project addressing how composites can reduce automotive load-bearing structures is being conducted by the Clemson University (Clemson, SC, US) Composites Center, the Clemson University International Center for Automotive Research (CU-ICAR) and Honda R&D Americas (Raymond, OH, US), with support from the University of Delaware Center for Composite Materials (CCM, Newark, DE, US) and funding from the US Department of Energy (DOE, Washington, DC, US).

The project’s focus, says principal investigator Dr. Srikanth Pilla, who is the Jenkins Endowed Professor of Automotive Engineering and Dean's faculty fellow at Clemson, is the question of whether composites can enable ultra-lightweight closure systems — doors, hoods, trunk lids — to complement concurrent advances in powertrain technology and better aerodynamics: “Within the technology portfolio for lightweighting, much of the ‘low-hanging fruit’ has been implemented already — for example, engine downsizing. We believe there’s potential for efficiency gains in the area of load-bearing, structural closure systems at a reasonable price point.”

Collaboration, teaming are key

The four-year project, which began in 2016, came about as a DOE solicitation, part of the Obama administration’s series of Grand Challenges to further science and engineering on many topics, including meeting automotive emission standards. The request for proposal asked for design and development of a car door that offered a 42.5% weight reduction over a standard OEM door, while maintaining similar crash performance, durability and use/misuse performance, and similar noise, vibration and harshness (NVH) performance. And, regardless of how the lightweight door was designed, it had to use commercially available material systems and scale to production volumes of at least 20,000 vehicles per year.

Honda came on board as the research project’s OEM advisor because the project aligned with “our vision of ultimately creating an emission-free society,” says Skye Malcolm, principal engineer, Advanced Planning & Verification Vehicle Development Foundations at Honda R&D Americas. Honda also added its own constraints to the project, he adds: “The door design to be developed by the team must use the same sealing geometry, have all of the same functional equipment as the baseline door, provide a Class A finish indistinguishable from the baseline and meet Honda durability and aging requirements.” The team has brought an additional goal that the door be 100% recyclable. Perhaps most important, the DOE mandated a maximum allowable cost per pound of saved weight (over the baseline door) of $5. This meant that for a typical Acura MDX door weighing 31.8 kg, a 42.5% weight reduction would bring the overall target weight to 18.3 kg, which (at $5/lb of saved weight) meant the composite door could only add $150 to the cost of the door.

Supporting Pilla on the project are several undergraduate and graduate students, Dr. Gang Li, a professor of engineering mechanics at Clemson, and Drs. Bazle Haque and Shridhar Yarlagadda of the University of Delaware CCM, experts in multi-material composites. Yarlagadda, the project’s co-principal investigator, points out, “Honda has been an integral part of our effort and has provided an exceptional level of collaboration and commitment to our program, including HPC computing support and access to Honda engineers across the spectrum. Design, manufacturing and integration of composite components must be combined with a number of customer-driven ‘soft’ requirements to create an acceptable system design, and this would not have been possible without Honda support.” This sentiment is shared by the other team members, adds Pilla: “Simple material substitution was not a solution. We had to look at a systems approach, and Honda helped us to understand all of the door system elements down to the component level. Indeed, their partnership and involvement is unparalleled.”

Designing a new door

Initial analysis, included benchmarking of other OEM efforts at lightweight closures for limited market models, including Audi’s aluminum door frame for its A8 model, the Porsche Panamera magnesium door frame and BMW’s i8 carbon fiber-reinforced thermoset door frame. None of these previous OEM approaches, however, met this project’s cost or weight goals. Says Pilla, “I wanted to be part of something that would benefit the future, that would contribute to a circular economy. A thermoplastic door hadn’t been attempted before, and it would be recyclable.” When stacked up against other candidate materials, including thermoset composites, aluminum and steel, thermoplastics offered not only recyclability but very high potential for lightweighting and fast processing speeds (compared to thermosets) to meet production targets.

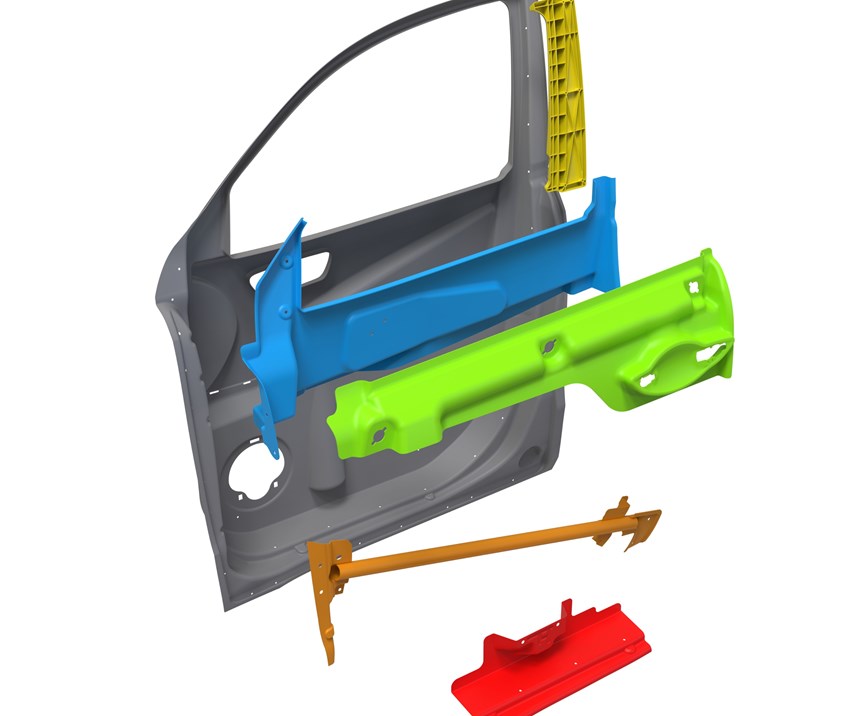

With the original Acura MDX door as the baseline (Fig. 1), the team broke down its material mix: 62% metal, 21% rigid neat polymer, 13% glass and 4% elastomer. The greatest opportunity for lightweighting, 60%, would come from the metallic door frame, which the team intended to reduce from a baseline weight of 15.4 kg down to the target weight of 6.2 kg. While there was no chance to reduce weight in the door’s internal components and electronics (radio speaker, servo for raising and lowering the window, door lock, etc.), the team determined the window glass weight could be reduced by 20%, perhaps making the glass thinner but without compromising the target metrics of NVH and durability. Further, the team estimated that the weight of trim elements on the door’s inner surface could be reduced by 30%, or even eliminated.

The project’s major tasks ran concurrently for the first two years. Some team members worked on material data generation, while others tackled door design specifics. The material data group generated material testing data for a variety of thermoplastics — continuous tapes, mats, short and long fiber-reinforced polymers and more — to determine candidate materials for the inner frame and outer panel; materials were contributed by a number of industry supplier partners. Data were evaluated via spider charts, with overall strength, shear strength, allowable cost, allowable density, stiffness and toughness making up the chart axes.

The best-performing material options following initial data evaluation — continuous fiber tapes and long fiber-reinforced thermoplastic pellets — underwent material modeling, explains Pilla: “It was possible to construct a simple orthotropic material stiffness matrix for the continuous fiber tapes, based on Hooke’s law.” For the long fiber-reinforced polymer, however, secondary simulations were needed to predict the strength and stiffness of an injection molded door part, because of anisotropy introduced by both the final part geometry and the mold-filling process. Adds Pilla, “Modeling of these long fiber materials is difficult, because not much has been done on simulation.” To gather the data needed, the team developed a manufacturing optimization loop. Generic part shapes for the door’s inner frame and outer panel were generated with Dassault Systémes’ (Waltham, MA, US) SolidWorks 3D design software; mold-filling simulations of those shapes were conducted to determine melt flow vectors with the aid of Moldex3D software from Moldex (Chupei City, Taiwan); melt flow dynamics and collusion were analyzed to determine fiber orientation via Digimat software from e-Xstream (Hautcharage, Luxembourg, a Hexagon company); and mapped fiber orientations were used to generate a stiffness matrix using finite element analysis (FEA) tools, including material cards supplied by Altair Engineering Inc.’s (Troy, MI, US) HyperWorks CAE solution. As part shapes were modified, and as materials were tested, the optimization loop was repeated multiple times.

Concurrently, other team members worked on actual door concept development, and eventually, tooling and manufacturing simulations. Starting with rough sketches and high-level material selection, a range of designs was created. Then, rough CAD models were generated, along with initial FEA simulations for simple static load cases. In the fall of 2016, says Pilla, a design workshop was held at CU-ICAR where the team narrowed the door concept options down to seven, for further work. “Our design philosophy from the start was to maximize functional integration of parts and materials, minimize part count, maximize effectiveness of materials utilized through optimization and simplify assembly,” says Pilla.

At this point, detailed CAD models were generated and FEA simulations were performed for each concept to validate static performance in compliance with Honda’s targets. Taking into account manufacturability and integration of subsystems, Concept 7 (a space frame approach) began to converge toward Concept 2 (a one-piece structural frame), so the team decided to continue with Concept 2, incorporating lessons learned from the space frame approach. That concept consists of four elements: the outer Class A panel, the door internals, an inner frame or panel, and the interior trim elements.

Multi-material inner, Class A outer

The team selected materials and manufacturing processes for the final door design in mid-2018, with a design freeze on January 15, 2019; tooling manufacturing and prototyping has begun. Figure 2 shows the details for the 1.2-mm-thick inner frame and its components (the outer Class A panel is not shown). “Beltline” refers to a styling line formed by the lower edge of the window glass, where stiffeners have been placed to help support the molded composite panels. Pilla notes that the anti-intrusion beam, for passenger protection in the case of a side impact, had to remain in steel to keep overall door weight lower — a composite beam with the same performance would have been too heavy. One key element of the design is the fastening system for connecting the inner frame to the outer panel. Pilla explains: “The outer Class A panel will be attached to the door at the end of the assembly line, which will allow associates to easily install the door internals beforehand, and also prevent any damage to the Class A surface during assembly.” Molded snap-fit features on the inner frame are adjustable, to accommodate manufacturing tolerances in the Y direction, he adds, while slotted holes for metallic fasteners help to compensate for manufacturing tolerances in the X and Z directions, during assembly.

To help with weight reduction, the current door design has no conventional interior trim panel. Instead, a few functional molded parts were designed, including an injection molded map pocket, an arm rest of natural wood back-molded with ABS plastic, and some leather padding laminated with foam. Together, these parts weigh 1.34 kg, as compared to the baseline interior panel at 3.49 kg. Pilla says the team expects to save more weight with design optimization.

Currently, FEA analysis and optimization is underway, to model both static load cases and dynamic crash loads that the composite door will have to withstand. The static load cases alone are daunting, and include door sag, beltline stiffness, mirror mount rigidity, door handle pull rigidity and more. The dynamic load testing, says Pilla, for now consists of the Federal Motor Vehicle Safety Standard (FMVSS) 214 quasi-static pole test, in which a vehicle door is crushed inward by a pole (which misses the roof and body) for 18 inches while all minimum force requirements are maintained: “This case is the least computationally intensive in comparison to the other two crash tests [the 75° FMVSS 5th Percentile Female (AF5) Pole test and the Insurance Institute for Highway Safety Side Impact Criteria Evaluation (IIHS SICE) test]. This will enable us to conduct more design experiments and optimization loops.”

Adds Gang Li: “The integration of the composite manufacturing process and structural performance simulations with optimization algorithms is both intriguing and challenging. While the challenge lies in the complexity of the system and the scale of the computations involved, such integration merges the structural, material and manufacturing process design spaces together and provides us more opportunities for lightweighting and enhanced performance.” And, meeting this pole test load case means the door is close to meeting the other two pole and side impact tests, he adds.

“Our tests so far show that the composite door easily meets the federal requirements, but our baseline Acura door’s comprehensive performance is much higher than those requirements,” says Pilla. FEA results so far show that the lightweight composite door absorbs more energy than the baseline door (23.59 kJvs.15.34 kJ) which Pilla attributes to composites’ ability to absorb additional deformational energy after the initial yield point. But, simulations show that improvements can be made, both to the outer beltline stiffener and to the reinforcement architecture of the inner frame.

With one year remaining in the initial project timeline, the group is generating manufacturing simulations and tooling approaches; creating a mass production plan for scale-up and estimated costs of a production line; and producing prototype(s) for crash and mechanical performance testing, fit and finish tests, and accelerated aging.

Says Pilla, “The composite door is still not achieving the target, due to the panels’ thicknesses, and it is not completely optimized. While we’re much lighter than the steel baseline, we have not yet met our 42.5% weight reduction goal, but we’re optimistic we can accomplish it.” A prototype door for fit and functional testing will be ready soon. The project team believes that the materials and technologies developed for this door can easily be scalable to other automotive components (for example, bolt-on and body-in-white parts), and the relatively low infrastructure cost of the composites processes can enable new OEMs and suppliers to implement these technologies — a win for automotive composites.

Related Content

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreDeveloping repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More