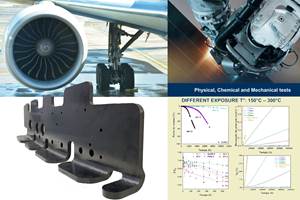

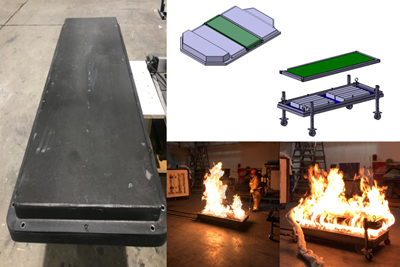

This prototype battery enclosure tray built by CpK Interior Products Inc. aimed to demonstrate the company’s UniFORM process, which adds proprietary specialized tooling and vacuum assistance wet compression molding to achieve higher performance composite parts at a lower cycle time and process cost. Photo Credit, all images: CpK Interior Products Inc.

CpK Interior Products Inc. (Corbyville, Ontario, Canada) is a division of automaker Stellantis (Hoofddorp, Netherlands) specializing in materials for and manufacture of interior automotive components like instrument panels. The company recently added composite battery enclosures to its product list, after developing a process for building high-quality, high-complexity boxes and trays with a low cycle time and low tooling costs.

“We’re vertically integrated, and mostly work on materials development for automotive interior applications,” explains Dr. Gregory Farrar, head of R&D at CpK Interior Products.

The company operates four facilities within the Ontario/Detroit, Michigan region, each serving one step in the process of building plastic or composite automotive components. The resin compounding facility in Belleville, Ontario, produces plastics such as flexible polyvinylchloride (PVC), thermoplastic polyurethane (TPU) and other thermoplastics. This facility also serves as a research and development (R&D) center, including work on new product areas and new materials, such as natural fiber composites and graphene-reinforced composites.

Materials from Belleville are shipped to Port Hope, Ontario, where they are manufactured into plastic components or combined with fiber reinforcement to build composite components using the company’s processing capabilities: injection molding, resin transfer molding (RTM), thermoforming and more. Parts are finished and assembled at the Guelph, Ontario, facility prior to OEM delivery. And a fourth facility in Auburn Hills, Mich., U.S. serves as the design headquarters and includes product engineers and program managers.

EV battery boxes: Lower cycle time, higher quality

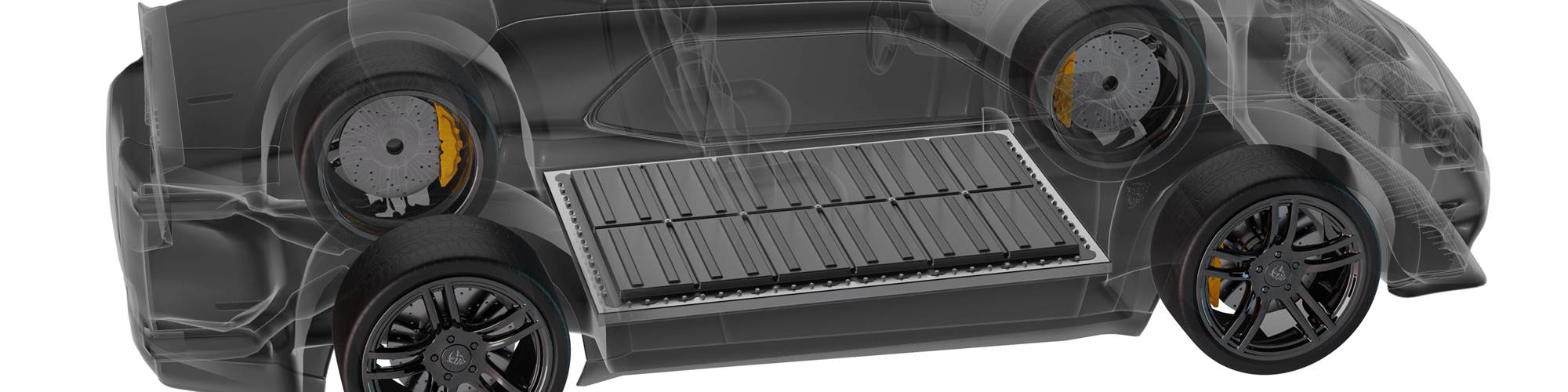

Now, the company is entering the world of composite battery enclosures, building on its current expertise and location. Farrar explains, “The electric vehicle [EV] battery supply chain is growing in Ontario, with a need for lightweight enclosures. We want to seize this opportunity and become part of the supply chain.”

Dr. Murali Reddy, lead for R&D and sustainability at CpK Interior Products, notes that many companies are working on composite battery enclosures because of the known benefits compared to metals: Lighter weight, greater ability to control thermal management or contain thermal runaway issues, no corrosion and more. CpK Interior Products wanted to combine its experience building low-cost, high-quality plastics and parts with the benefits of composites in this type of application.

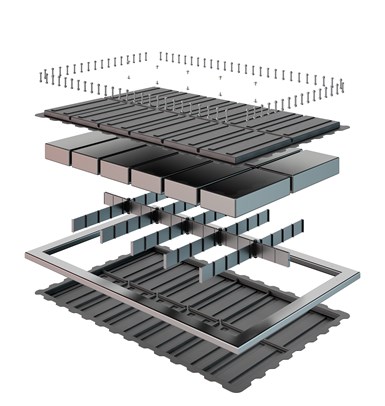

In CpK Interior’s battery enclosure design, carbon fiber composites would be used for both the top and bottom trays and the battery dividers.

In 2019, the CpK Interior Products team began by comparing the cycle times, part quality, possible part complexity and tooling cost for various processing methods: wet compression molding (WCM), high-pressure resin transfer molding (HP-RTM) and prepreg with autoclave cure.

HP-RTM and autoclave processing produced high-quality and highly complex parts, but at relatively high cycle times and high tooling costs, whereas WCM enabled production of parts quickly with low tooling costs, but with lower relative quality and complexity.

CpK Interior Products, therefore, set out to develop a method for manufacturing battery enclosures with the quality and complexity of autoclave or HP-RTM processing, but at the lower cycle time and tooling costs of WCM.

The project, a collaboration with several industry partners, involved both materials development and testing, and process design. Beginning in the R&D lab, the resulting process, called UniFORM, “combines WCM with a proprietary tool design, where we use a vacuum in the tooling to enable us to produce high-quality parts with very low cycle time,” says Reddy.

He explains, “The way it works is we lay down the fabrics into the tool, apply the liquid resin, close the tool. The tool is held to the cure temperature of the resin, and we pull the vacuum, and the part is formed.” The process ends up being sort of a hybrid between vacuum-assisted HP-RTM and WCM, with the three key elements being vacuum-assisted tooling, high-temperature cure and snap-cure resins. Depending on the complexity of the part design, the process was demonstrated with or without preforming needed.

Reddy notes that a variety of carbon fiber types were tested and confirmed for feasibility so far, and that cycle times of less than a minute were achieved for several materials. Recycled and twill materials were tested as well, resulting in longer cycle times of up to three and a half minutes.

First battery tray prototypes

To put its new technology to the test, in 2021, the company entered a competition by a North American OEM focused on battery enclosure design. The enclosure, per the required specifications, featured a carbon fiber/epoxy top and bottom tray, and included metal and injection-molded plastic inner frame components.

On the composite trays, finite element analysis (FEA) modeling was used first to analyze properties such as impact resistance, crush resistance and structural stiffness versus steel or aluminum. The CpK Interior Products model passed each OEM requirement.

The company hopes this first R&D effort leads to new opportunities to leverage its research, materials development, fabrication and assembly capabilities to the EV battery market.

Ultimately, tooling and a prototype were built using the UniFORM technology. “We tested the possibility of producing the battery box without any preforms, just raw materials,” says Reddy. Each tray was produced in a two-minute cycle time, with 50% fiber volume. The resulting weight was 44 pounds per tray — an 86.4% weight reduction versus the 324-pound steel version and a 60% weight reduction versus the 110-pound aluminum version. And overall part thickness measured to 3 millimeters, sized 2,061 millimeters x 1,361 millimeters. “We were quite successful,” he says.

CpK Interior Products continued running internal tests – on electromagnetic interference (EMI) shielding and other properties – to produce a full data set on its capabilities to provide for potential customers.

The ultimate goal, says Farrar, is to leverage each of CpK Interior’s capabilities — R&D, design engineering, materials development, fabrication and assembly — to fill the need for lightweight, high-quality composite battery enclosures at a realistic price point and cycle time for the automotive market.

Related Content

Rocket Lab begins installation of large AFP machine for rocket production

The 99-ton AFP machine, custom-designed and built by Electroimpact, is claimed to be the largest of its kind, expecting to save around 150,000 manufacturing hours in the Neutron rocket’s production process.

Read MoreDawn Aerospace reusable rocket-powered aircraft flies twice in one day

Eighth and ninth flights of composites-intensive Mk-II Aurora reach an altitude of 63,000 feet, demonstrates same-day reusability capability for rocket-powered systems.

Read MoreParis Air Show 2023 highlights

The Paris Air Show, one of the largest aerospace trade shows in the world, returned for the first time since 2019 and proved that the global aviation industry industry is very much alive and kicking.

Read MoreDaher CARAC TP project advances thermoplastic composites certification approach

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

Read MoreRead Next

Multi-material toolbox for cost-effective, scalable EV battery enclosure design

Mexico-based automotive Tier 1 Katcon has developed a “toolbox” of material, process and joining options aiming to serve a range of electric vehicle requirements.

Read MoreDesigning a versatile, multi-material EV battery enclosure

Continental Structural Plastics has developed one-piece, compression-molded composite covers, an innovative fastening system and a range of material options to meet OEM needs.

Read MorePrice, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

Read More

.jpg;width=70;height=70;mode=crop)