Update: GE identifies cause of blade breaks

Clarifications regarding materials and processes, plus GE reports on root cause of blade breaks

Share

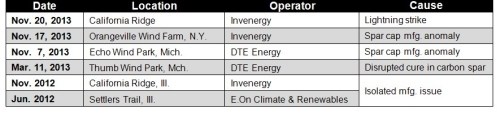

CW Blog reported on Nov. 22 about blade breaks on GE wind turbines. We have since received several clarifications regarding materials and processes used to manufacture those blades. Also, GE has released its report on the root cause of all four blade breaks this year.

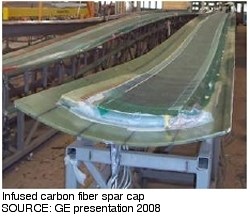

First, Ventura Pobre did not help develop the carbon fiber material nor process used by the Brazilian blade manufacturer Tecsis (Sorocaba, São Paulo state) in the GE 48.7m blades. Though Tecsis does develop materials and processes for blades it supplies to smaller and domestic customers, for its large subcontract programs — e.g. GE, Siemens and Alstom — materials and processes are specified by Tecsis’ customers. Tecsis then completes qualification testing to validate that it meets the customer-specified requirements before it can manufacture those blades. Based on import logs for the Brazilian state of São Paulo and Gurit annual reports, it is believed that Tecsis uses Gurit (Isle of Wight, U.K.) carbon fiber Sparpreg to manufacture the spars used in the GE 48.7m blades. When asked to confirm, GE responded, “The breakdown of our suppliers is confidential information.” However, neither GE nor Tecsis denied using Sparpreg.

In GE’s technical documentation for its 1.6-100 turbines, the blade weight is listed as 6,500 kg (14,330 lb), which is indeed a reduction (28 percent) from Tecsis’ previous 50m blade weight of 9 tons (19,842 lb). This matches well with details reported in the October 2012 issue of Composites Techology magazine in an article titled, “Wind turbine blades: Glass vs. carbon fiber,” where GE was reported as specifying carbon fiber for its next-generation 48.7m blades and Dr. Philip L. Schell, executive VP of wind energy at carbon fiber manufacturer Zoltek Corp. (St. Louis, Mo.), estimated at least a 20 percent weight reduction when moving from an all-glass blade to one with a carbon fiber spar cap.

Meanwhile, North American Windpower reported on Dec. 19 that GE has identified a "spar cap manufacturing anomaly" as the root cause of the blade breaks at the Orangeville Wind Farm in New York and Echo Wind Park in Michigan. GE also said that the Nov. 20 blade break at Invenergy's California Ridge wind farm in Illinois was not related, but instead resulted from extreme weather that night. An Invenergy spokesperson told NAW that the blade was struck by lightning. The other 133 turbines at California Ridge remain operational, and GE is repairing the 134th unit.

At Invenergy’s Orangeville Wind Farm, GE personnel are inspecting each individual blade thoroughly. Invenergy is resuming commissioning and returning to operation those turbines that have been cleared by GE. NAW reports that DTE Energy and GE are still in the blade-by-blade review process at Echo Wind Park, which they expect will continue into January, with some turbines possibly resuming operations once they are cleared.

GE reported that of the “suspect population” it identified, which represents roughly 1.5 percent of the total blades in its global fleet of 22,000 wind turbines, all have been analyzed and only a “small “percentage” of those have been identified as affected by the spar cap manufacturing anomaly. Spokesperson Lindsay Theile told NAW, “We’re working with our customers to replace any impacted blades and get the turbines back up and running as quickly as possible.”

GE spokesperson Katelyn Buress provided earlier comments to CW: “Working with our customers, we have assigned dedicated teams to perform thorough investigations of the recent breaks. GE’s global fleet of wind turbines have recorded more than 500 million safe operating hours and achieved an availability rating of more than 98 percent. Our success in the industry is built on our high reliability and safety record. We are working closely with our customers to keep their turbines running reliably and safely.” Thiele indicated that GE has put additional controls and oversight in place to prevent this type of manufacturing issue in the future, including GE inspectors who are performing additional quality reviews and verification of data.

Related Content

RTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

Read MoreAchieving composites innovation through collaboration

Stephen Heinz, vice president of R&I for Syensqo delivered an inspirational keynote at SAMPE 2024, highlighting the significant role of composite materials in emerging technologies and encouraging broader collaboration within the manufacturing community.

Read MoreJEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More