Using 3D printing for composite molds and tools: the trend continues

Additive manufacturing (AM), or 3D printing, is becoming more common in the aerospace tooling realm. Production tooling can be made quickly and on-demand, which helps the tooling industry keep pace with accelerating composite part design cycles and demand for faster overall part processing speeds.

Share

Read Next

small.jpg;maxWidth=600)

Stratasys is introducing a new sacrificial 3D printed tooling solution, on display at RAPID and SAMPE Long Beach.

You may remember my article in CW magazine about a year ago (here’s the link: http://www.compositesworld.com/articles/a-growing-trend-3d-printing-of-aerospace-tooling) about how additive manufacturing (AM), or 3D printing, is becoming more common in the aerospace tooling realm. Fixtures, prototyping tools and even production tooling can be made quickly and on-demand, which helps the tooling industry keep pace with accelerating composite part design cycles and demand for faster overall part processing speeds. CW is seeing many examples of this, including a blog posted this week by Jeff Sloan about Oak Ridge National Laboratory (ORNL) and its progress in this area (here’s a link: http://www.compositesworld.com/blog/post/3-d-printing-autoclavable-composite-molds).

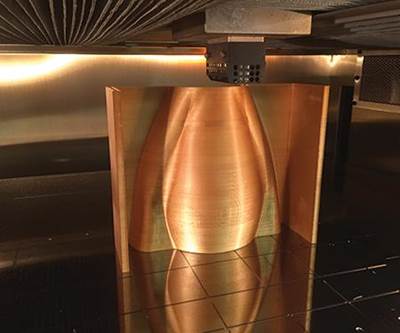

Solid evidence of this tooling trend can be found at the RAPID show (happening now, this week, in Orlando, FL, US) and the upcoming SAMPE Long Beach event next week, at the Stratasys booth (at RAPID, Booth 1014; at SAMPE, booth I32). Tim Schniepp, who is the Composites Tooling director at Stratasys, shared some insight with me regarding projects his company is involved with that will be on display at the both exhibitions. The first is a 3D printed sacrificial or trapped tooling solution. Using a new material that the company calls ST-130 together with a patent-pending “alternative fill” printing pattern, the trapped, washout tooling is designed for rapid build speed, fast dissolution, and high quality that can be autoclaved. The material and process were used to create a tool for Swift Engineering that allowed production of a complex hollow engine inlet duct (see photo), which will be on display. The president of Swift Engineering, Rick Heise, says “Stratasys-produced composite tools allow us to develop products much faster without compromising quality or performance of the parts.”

small.jpg;maxWidth=600)

This ULTEM 1010 tool for Dassault can stand up to autoclave pressures and cure temperatures.

Secondly, Stratasys has launched a comprehensive design guide, entitled “Design Guide for FDM Composite Tooling,” that lays out the best practices for design, fabrication and preparation of 3D printed composite tools that can be used to cure composites at temperatures exceeding 350 °F and pressures of 100 psig, says Schniepp, when ULTEM 1010 resin material (supplied by SABIC, Pittsfield, MA, US) is used for the build (FDM is fused deposition modeling). Stratasys 3D printed composite tooling using ULTEM 1010 enables manufacturers to produce high temperature (>350°F), autoclave-cured composite structures in a fraction of the of time that traditional metal tools require, while also providing significant cost savings. Schniepp will present a technical paper at SAMPE regarding the design guide, entitled “Design Guide Development for Additive Manufacturing of Composite Tooling” on Thursday, May 26 at 10am, room 102 B, and the company will also host representatives from Dassault Falcon Jet at SAMPE to showcase and display their tooling design solutions for parts on the Falcon aircraft. “We developed the Design Guide to provide our customers with the ability to immediately realize the immense time and cost-saving benefits of FDM composite tooling without the effort and expense required to develop the knowledge independently,” says Schniepp.

To further assist customers, Schniepp says that Stratasys now offers an Acceleration Kit for its Fortus 900 printing machines, aimed at producing large tools. A larger extrusion tip and upgraded software package allows faster material laydown rate for faster builds. The acceleration kit is intended for ULTEM 1010 and ASA polymer materials.

Related Content

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreBusch expands autoclave solutions

Busch announces its ability to address all autoclave, oven and associated composites manufacturing requirements following the acquisition of Vacuum Furnace Engineering.

Read MoreVIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreRead Next

A growing trend: 3D printing of aerospace tooling

Toolmakers and OEMs are embracing additive manufacturing for customized, rapid tools, masters and jigs.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More