VBO prepreg on wing structure

GE Aviation scores first use of OOA wing trailing edge on large commercial aircraft.

GE Aviation’s aircraft manufacturing facilities at Hamble-le-Rice, UK, acquired in 2007 as part of GE’s acquisition of Smiths Aerospace, had a long history of aviation innovation dating back to Britain’s WWII fighter, the Spitfire, and was the production site over the past two decades for composite parts destined for numerous aircraft platforms, including Airbus and Boeing commercial and military programs.

In 2008, a year after it acquired the site, GE won the largest contract in the Hamble plant’s history: to design and manufacture the entire wing fixed trailing edge, including the trailing edge secondary structure, for both versions of the new Airbus A350 XWB. The composites challenge that this package gives GE shouldn’t be underestimated: It includes all the upper and lower panels that make up the trailing edge aft of the wing rear spar and the leg fairing door and hinge panels for the aircraft’s main landing gear.

Given the facility’s history, it also was fitting that GE Aviation elected to form the composite secondary structure from out-of-autoclave (OOA), vacuum bag only (VBO) prepreg — a commercial aviation first — using a technique that GE Aviation Hamble has carefully matured over a period of almost 15 years. The OOA technology was originally developed in a UK-funded R&D program and then industrialized for the high-performance automotive industry. GE Aviation transitioned the technology, making it suitable for aerospace use. The new A350 XWB has become the stage for its production debut.

The fixed trailing edge part package comprises about 90 panels per aircraft. Two-thirds of the panels were made from Cytec’s (Heanor, Derbyshire, UK) Airbus-qualified MTM44-1 OOA prepreg, using a 6K 2X2 twill Tenax HTA carbon fabric supplied by Toho Tenax Europe GmbH (Wuppertal, Germany). Interestingly, the use of OOA material, which can be cured at lower pressures, gave GE some additional design benefits. As is conventional for such aircraft parts, a sandwich construction was used, with aramid paper honeycomb core placed between composite faceskins. GE designers have used a mixture of the well-known Nomex honeycomb and the more recently qualified and lighter-weight N636. Additionally, with a carbon fiber wingbox and higher loads on the A350 fixed trailing-edge structure, thicker honeycomb islands with steep ramp angles were required. One of the challenges to overcome was that the honeycomb might collapse during the conventional autoclave process. Apart from throughput and cost advantages the GE OOA process is expected to bring, their process for the most part has eliminated this technical risk. Early in the project, a decision was made to design the largest, most heavily loaded panels using in-autoclave materials to reduce risk. However, in light of the positive experiences with the OOA process, these types of parts could also potentially be designed for OOA manufacturing.

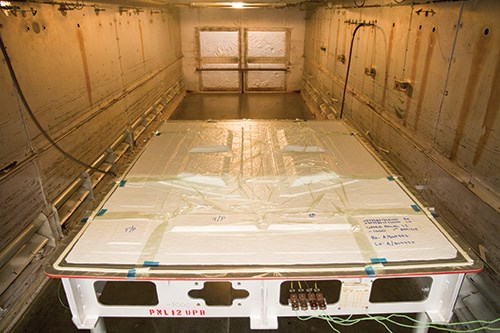

Typical VBO prepreg panels, such as the trailing edge Upper Panel 12 (in Fig. 1, at left) were layed up under cleanroom conditions on the mold tool, then vacuum bagged and moved to the oven for cure. Fig. 2 shows Upper Panel 12 in the oven (note that thermocouples are installed on the underside of the mold tool). During cure, cycle times and temperatures for the OOA MTM44-1 system are comparable to those for conventional 350°F/177°C autoclave-cure materials but the cure cycle is without the complexities of control of positive pressure. Full vacuum only is maintained throughout the cycle. Following cure, the upper panel was vacuum-secured to a machining fixture within a CMS (Caledonia, MI, US) machine for final machining and drilling. That fixture also is the final buy-off fixture for the panels to prove that the product is correct to model. Fully machined upper panels, drilled and countersunk, require a pin check and deburring before transport to the NDT facility, where they are reviewed using ultrasonics for possible faults and defects during layup. After successful completion of this process, the panels are moved to paint, prior to assembly. Panel quality is comparable with conventional autoclave-cured honeycomb sandwich panels, with porosity levels that reportedly meet all customer requirements.

“It’s all about cost and rate nowadays,” explains John Savage, technical authority composites. “OOA [prepreg] is well positioned to tackle both these requirements, while it also provides a simpler production system compared to in-autoclave usage for certain applications.”

GE Hamble has proven the throughput and cost principles of this process in its high-performance automotive programs. As the new A350 XWB has become the stage for its production debut in an aerospace environment, validation of the advantages is anticipated when stable and mature production has been reached.

The current package requires GE to deliver about 14,000 composite parts per annum, which will rise with the projected demand for more aircraft. To meet the projected demand, GE, as part of a five-year, US$50 million-plus investment at the Hamble site, has developed a new 9000m2 composites production facility. Both in-autoclave and OOA operations will be housed in the new center.

The new facility reportedly will incorporate the very latest factory automation technology to improve the efficiency of the long established hand lay-up manufacturing technique: Tool movement and tracking will use advanced technology, driven through the Manufacturing Execution System (MES). Layup tools and product will be tracked through the factory, using wireless technology. Control systems have been integrated into the layup stations to automate the services and the projection lasers, both of which are automatically driven through the MES. Automation and advanced material handling is a theme carried throughout the new composite facility, in line with the principles of Industry 4.0.

Building on this success in OOA technology, GE Aviation is focusing R&D efforts on creation of other materials and manufacturing processes, both in- and out-of-autoclave, together with optimizing composite design methods through a number of UK government and EU-funded research and technology programs. GE Aviation Hamble is set for a busy future.

Related Content

SAM XL demonstrates closed-loop digital methodologies via full-size aerocomposite parts development

PeneloPe Project’s modular, zero-defect manufacturing deliverables are being highlighted in an upcoming video that demonstrates the resulting aerospace pilot line’s feasibility.

Read MoreIMDEA introduces digital twin for real-time analysis of composite materials production

Newly designed digital twin by IMDEA and Technical University of Madrid researchers enables manufacturers to see inside composite materials as they are being produced, facilitating early detection of faults.

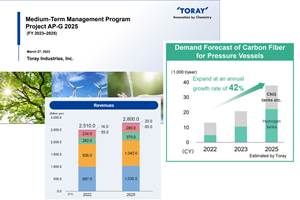

Read MoreToray announces growth, investment in carbon fiber composite materials

As part of its 2023-2025 management strategy, Toray projects 42% growth for pressure vessels, 30% growth in carbon fiber composite materials revenue and a doubling of capital investment.

Read MoreST Engineering MRAS presents initiatives to drive autoclave efficiency, automation

During a JEC World 2024 panel discussion, the company revealed ways in which it is maximizing throughput and efficiency of its autoclaves and enhancing composites production processes.

Read MoreRead Next

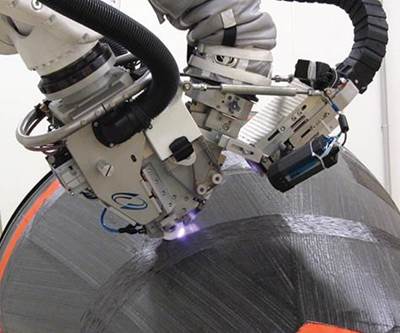

Dry fiber placement: Surpassing limits

Coriolis Composites’ automated aerostructures manufacturing using dry materials moves from development projects to production.

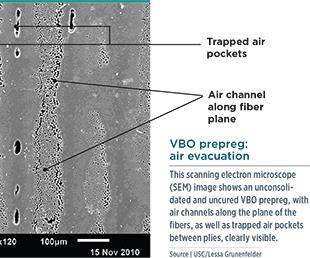

Read MoreResearch on OOA processing continues

Much work has been done to make OOA processing practical for aerospace applications, but much work still remains if it is to become the compelling option.

Read More