Volvo 65: Identical and optimal composite spars and rigging

“One design” concept takes the boat out of the yacht-racing equation, pitting teams against the wind, sea … and each other.

For the 2014-2015 Volvo Ocean Race, which began at its home port in Alicante, Spain, on Oct. 11, 2014, and ended June 27, 2015, in Gothenburg, Sweden, all seven competing 65-class sailboats were built to a single design. Why? According to the Race Web site, it was so the outcome would be determined not by who had the best boat, but by who had the best sailing skills: “The 2014-15 Volvo Ocean Race will be won and lost by the athletes, out on the water — let the best athletes win.”

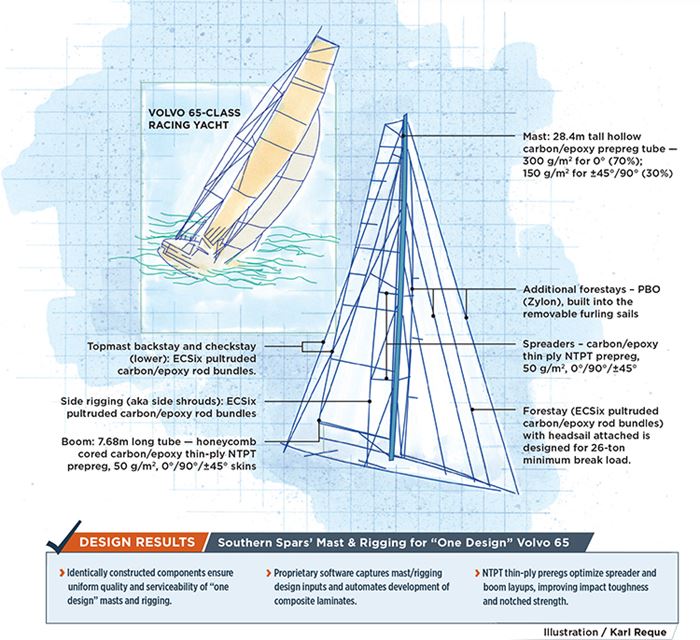

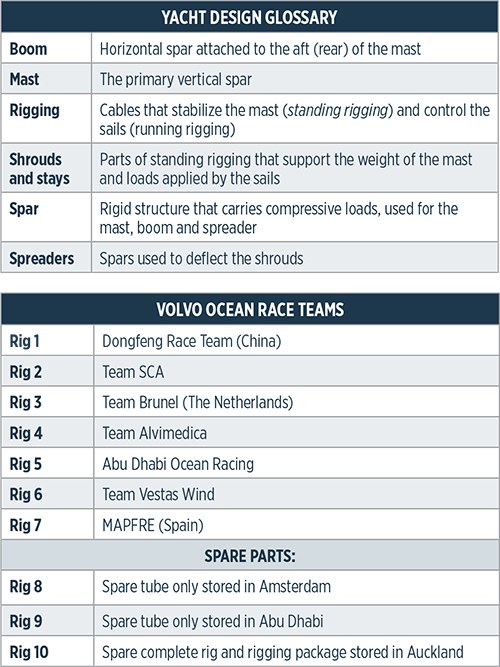

That didn’t mean the boats would be less than the best. The “one design” concept was promoted by noted racing yacht designer Farr Yacht Design (Auckland, New Zealand) and the boats were built by a consortium of premier boatyards: Green Marine Ltd. (Hythe, Hampshire, UK), Persico Marine (Nembro, Bergamo, Italy), Decision SA (Ecublens, Switzerland), and Multiplast SAS (Vannes, France). Technical specifications included hull overall length of 22.14m, rig height (above water) of 30.3m, mainsail area of 163m2, and an empty boat weight of 12,500 kg. To ensure that the composite spars (masts, booms and spreaders) and composite rigging (cables) — one complete set for each of the seven competing boats, plus three full sets to be shared among competitors as spare parts — were identical and optimal in design and construction, Southern Spars (Auckland, New Zealand), part of the North Technology Group (Milford, CT), was enlisted as sole spar/rigging supplier.

Tried-and-true digital design process

Southern Spars’ design team leader Jarrad Wallace uses the North Design Suite of software from North Sails (Minden, NV, US) for its global design of spars and rigs. “In addition, we have developed our own proprietary front-end software, which captures design input data and automates the process of stepping through North’s various software packages.”

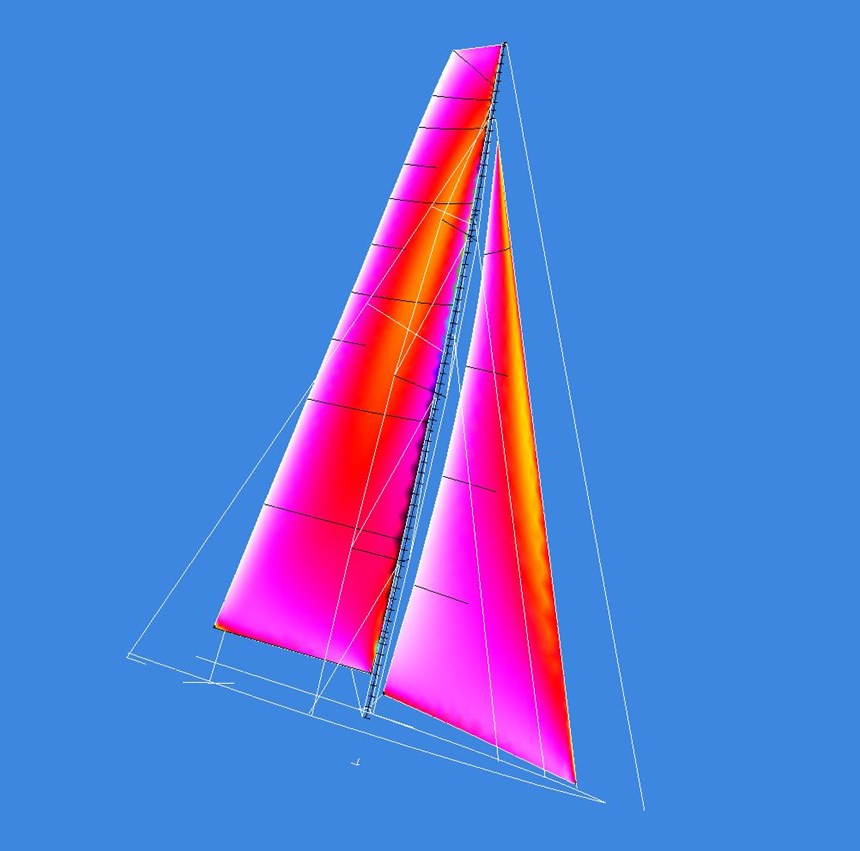

The first package is Desman, which builds a three-dimensional model of the sail-and-rig system. “We start by defining the rig geometry in Desman,” Wallace explains. “Using numbers, we enter the basic elements of the rigging, mast and spreaders, showing their size and stiffness and where they all attach to the boat. Then we add the sails.”

The Suite also includes the Flow computational fluid dynamics software package, used primarily to simulate airflow over the sails. For this step, Southern turned to North Sails, which used Flow to develop pressure files built around specific sail shapes, sail trim and sail sizes, and saved the results in a library of pressure files. From that library, Southern chose the most appropriate pressure file for its Volvo 65 spar-and-rigging model.

Then, the Suite’s Membrain finite element analysis (FEA) package was put into play. In this step, Southern took data from the Desman model and Flow simulation to apply pressure to its 3D model. Membrain uses beam elements — slender structural members that offer resistance to forces and bending under applied loads — the properties of which are derived from Southern Spar’s in-house design tools.

“By simulating loads applied by the sails, we are able to extract all of the forces and moments on the mast, spreaders and rigging,” Wallace explains. (A moment is a measure of a force’s tendency to cause a body to rotate about a specific point or axis.) This enabled Southern’s designers to begin engineering the composites, specifying the spar and rigging properties and balancing the dynamic forces on the rig (rig tune and setup) to be optimal for the proposed use. “Membrain does such a good job predicting what the loads are going to be on the boat, that when we measure actual loads during sailing, we find the predicted loads are usually very closely confirmed,” Wallace says.

Mast math for compression, bending loads

To meet the required bending moment (~7,000 kg/m) and compression loads (49,800 kg) that could be imposed on the hollow mast shells, a 3.8-mm thick wall was built up from prepreg supplied by Gurit (Zurich Oerlikon, Switzerland), made from its SE84 epoxy resin system and high-modulus (377 GPa) M40J carbon fiber from Toray Industries (Tokyo, Japan). For longitudinal (0°) fibers running top to bottom on the mast, heavier 300-g/m2 prepreg was used. “The predominant compression and bending loads in the mast rely primarily on compressive stiffness and strength, so about 70% of the fiber is in the longitudinal direction,” Wallace explains. Because shear forces are smaller in comparison, lighter 150-g/m2 fiber was used for ±45° and 90° off-axis prepregs.To achieve the rigorous performance levels the racing teams would need, the mast also required significant detailing: 202 carbon fiber prepreg uni tapes were located according to a specified fiber architecture along the length and around the circumference of each mast. Unidirectional, and in some cases, woven, prepreg patches reinforced areas exposed to high stress concentration and unusual stiffness demands around fittings, holes and, for example, the top of the mast, where it is cantilevered above the cap shroud (the highest attachment point of the side stays). The mast’s transverse bending stiffness, 5,100 kNm2, peaks through the Cap Shroud attachment and then tapers towards the masthead.

The 10 masts were layed up in two identical female molds and cured in an autoclave at 120°C.

Thin-ply spread tow for spreaders and booms

For the laminate design of spreaders and booms, Southern took advantage of thin-ply prepregs developed by North Thin Ply Technology (NTPT, Penthalaz, Switzerland), also part of the North Technology Group, specifying 50-g/m2 UD tape made from Toray T700 standard-modulus, 230-GPa carbon fiber tow in a 120°C epoxy resin system.

Preforms made from these very thin, limp tapes were layed by an automated tape laying (ATL) machine that was custom-built by NTPT for Southern with a 28m by 4.5m workzone for this purpose. A typical preform consisted of two to three layers of tape in multi-directional orientation.

Use of thin-ply layers improved the strength and impact toughness of the spreaders’ relatively thin shells, Wallace says. He adds that testing during NTPT thin-ply laminate development demonstrated that a laminate of many thin plies results in better impact toughness and notched strength, and is more resistant to crack propagation, than laminates of fewer plies of greater thickness.

The same NTPT 50-g/m2 prepreg was also used to build the thin, impact-resistant skins on the 7.68m, 68-kg racing box booms, wrapped around a Nomex honeycomb core. The preforms were then cut to shape on a dedicated cutting table to fulfill the design of the ply schedule and layed up in female molds for autoclave cure at 120°C.

ECsix multi-strand rigging

For most of the rigging — seven stays per set, comprising two side shrouds, one forestay, two checkstays and two backstays —

Southern selected ECsix cables. ECsix is a registered trademark of Composite Rigging (North Kingstown, RI, US), a member of the Southern Spars Group. Each cable consists of bundles of pultruded 1-mm or 3-mm rods, using Toray’s T800 carbon fiber in an epoxy resin matrix. Composite Rigging customizes the bundles for each sailboat specification. “We gave Composite Rigging the stiffness required for each stay, and how much load it would be under, and they engineered the rigging to determine how many rods would be needed in each and every bundle,” Wallace explains.

The topmast backstays and checkstays, extending from the top of the mast to the ship’s stern, were designed and tested for a 26-ton minimum break load. The V1 side shroud — the primary side stay that supports the rig — was designed for a maximum static working load while sailing of 8,900 kg and a break load of 37,245 kilogram-force (kgf). Wallace notes, however, that “some of the headsails have their own forestay, which is built into the sail, and these are supplied by the sailmaker.” For the forestays in the removable furling sail, North Sails and Southern Spars specified cables made from poly (p-phenylene-2,6-benzobisoxazole) or PBO, aka Zylon, from Toyobo Co. Ltd. (Osaka, Japan). These cables were made by Future Fibres (Valencia, Spain), recently acquired by North Technology Group (see “Learn More”). PBO was chosen because it is more flexible and can more easily be packed with the furling sail in the sail bag.

And the winner was …

The 2014-15 Volvo Ocean Race was grueling: The fleet completed nine offshore legs, with “InPort Races” at the end of each leg. The final race from Brittany, France, to Gothenburg, Sweden, found the Abu Dhabi Team (UAE) ranked as the overall winner, with Team Brunel second (The Netherlands). The Dongfeng Race Team (China) took third despite a broken mast on the fifth leg as the boat rounded notoriously rough-weathered Cape Horn on South America’s tip. The entire mast was removed and replaced at the next port, Itajai, Brazil.

Race officials declared “one-design” a success, stating, “It was and is one of the most successful initiatives in the 42-year history of the race.” VOR credited the approach for fewer breakages than its predecessor, the Volvo Open 70; for considerably reducing costs for the teams, driven mainly by shared maintenance and parts; and for a more competitive event: In several legs, all seven boats finished within minutes of each other. Most telling? After a refit, the same boats will contest the 2017-2018 race.

Get the full story on the 2014-2015 Volvo Ocean Race here.

Related Content

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

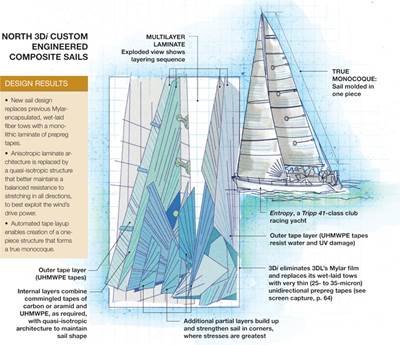

Custom-engineered composite performance yacht sails

North Sails introduces 3Di materials and process for structural composite sails.

Read MoreYachtbuilding Composites: Rigged for Success

Carbon composite cabling in several forms races ahead of dry fibers and stainless steel in sailboat rigging.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)