Wet compression molding

Automated process cuts cycle time and cost for CFRP parts with potential for 65% fiber volume via Dynamic Fluid Compression Molding variant.

Share

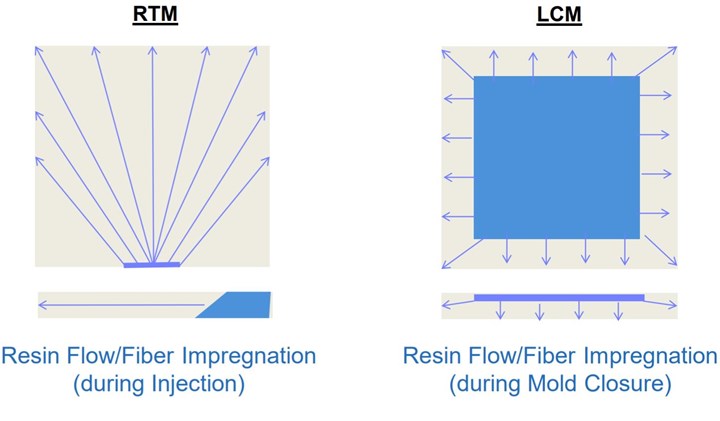

Wet compression molding, also called liquid compression molding (LCM), is a composites molding process where resin is applied to the top of a fabric blank. The wet blank is then transferred to the bottom tool in a set of matched molds, and compression molded in a press, which pushes the resin into the fabric, primarily in the z-direction.

SOURCE | Slide 10, “Liquid Compression Molding (LCM) Technology for Mass Production of Continuous Fiber Composite Epoxy Matrix Components”

Wet compression molding’s main advantages include the ability to apply resin outside of the mold, which frees up equipment for reduced cycle time and speeds resin impregnation versus the injection process required for resin transfer molding (RTM). The process also typically eliminates the preforming step, proceeding directly from wet fabric to a molded part. However, the process is best suited for flatter parts and less complex geometries. Also, both the blank and tooling must be designed to prevent wrinkles or other defects during molding.

Old becomes new again

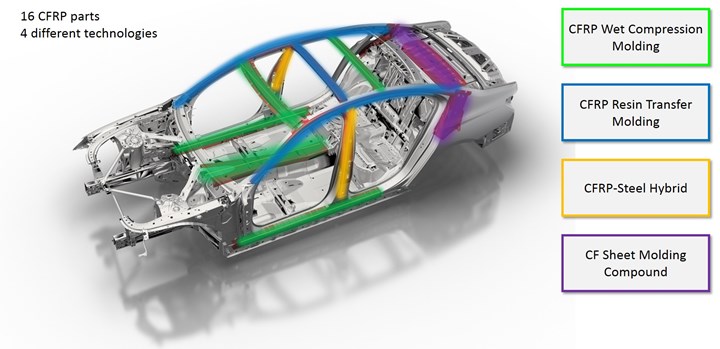

Wet compression molding is not a new process. Molded Fiberglass Companies (MFG, Ashtabula, Ohio, U.S.) claims it has used the process for volume composites production since 1948. Typically, compression molding has been used to process bulk or sheet molding compound (BMC or SMC), as well as thermoplastic materials such as glass mat thermoplastic (GMT). Wet compression molding, however, does not use prefabricated sheets of resin/thermoplastic polymer combined with discontinuous fibers, but instead begins with dry continuous reinforcements and liquid resin. Wet molding’s resurgence began with its use by BMW to produce multiple carbon fiber reinforced plastic (CFRP) parts for its i3 and i8 models as well as the side sills for its new 7 Series passenger compartment, referred to as the "carbon core".

The BMW 7 Series “Carbon Core” uses wet compression molding for side sills, tunnel and two of the roof bows. The process offers lower cycle time and cost vs. HP-RTM for parts with less complex geometry. Source: BMW AG

Wet molding manufacturing at BMW

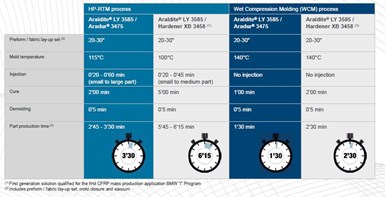

In the 2015 issue of Presses and More Composites, equipment and technology supplier Dieffenbacher (Eppingen, Germany) describes wet compression molding as a more economical alternative to high-pressure RTM (HP-RTM):

- Eliminating resin injection allows application of resin while other parts are curing in the press.

- The resin, usually epoxy, can also be more reactive because no latency is required to postpone cure until the RTM mold is filled.

- Dieffenbacher reports molding cycles cut to ~180 seconds and further productivity by pressing multiple components at once.

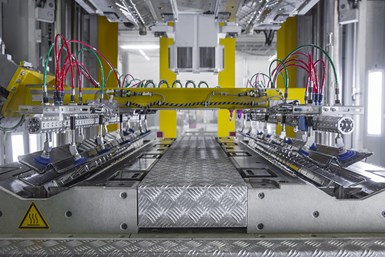

Dieffenbacher says wet molding enables a high degree of automation, including tool change systems so that changeover from one product to another is possible within ~10 minutes. BMW's wet molding line uses Dieffenbacher's CompressLite press designed for high-precision, energy-efficient operation.

Dieffenbacher's process chain begins with ultrasonically welded stacks of carbon reinforcements. These are transported by a robot with a needle gripping system to a table where a camera checks the position of the stacks and reports on the accuracy of the layers.

The stacks are corrected if required and then placed on a shuttle table with an integrated weighing system. Two resin robots apply epoxy resin to the stacks, a process which is weight-controlled to ensure part reproducibility and quality. The resin cabin's ventilation system can handle 5,000 m3/hr for venting of fumes during this open process.

After the robot places the stacks into the mold, the press closes and cures the stacks at 150ºC. Once the press opens, a robot extracts the cured parts and places them into a cooling press. Cooled parts are then removed and placed on a discharge conveyor for quality inspection before being queued for vehicle assembly.

Cost

According to the 2015 SPE ACCE paper "Evaluation of a New ‘Inline Prepreg’ Process Approach to Established Processes for the Manufacturing of Structural Components out of Carbon Fibre Reinforced Plastics” presented by Fraunhofer Institute for Chemical Technology ICT (Pfinztal, Germany) and the Institute for Vehicle System Technology FAST at the Karlsruhe Institute for Technology (Karlsruhe, Germany), wet compression molding offers lower material cost and higher production capacity than autoclave or inline prepreg. The paper calculates a part cost of 70€, raw material cost of 49 €, daily production rate of 294 parts (>73,000 parts/yr) and staffing of four workers and one foreman per line. That line was calculated to include an automated cutting table, fiber storage units, a handling unit, a resin application unit, a press, a tool and finishing station.

Resins

Dow Automotive Systems (Horgen, Switzerland) announced at JEC Europe 2014 (Paris, France) that its low-viscosity, fast-cure VORAFORCE epoxy resin held particular promise for the wet compression molding process. Working with KraussMaffei (Munich, Germany) and Cannon (Peschiera, Itlay), Dow developed a process that applies resin in 15-20 seconds and cures in 30 seconds, for a total manufacturing time of less than 60 seconds. However, part complexity was still limited, with the process most suitable for relatively flat or lightly contoured parts.

Hexion (Columbus, OH, US) has also developed epoxy resins for liquid compression molding, offering a total cycle time of 75-135 seconds with additional reduction possible by replacing part of the in-mold cure with a postcure.

Dynamic Fluid Compression Molding (DFCM)

Huntsman's DFCM process using Araldite epoxy resins offers cycle times as low as 1.30 minutes. SOURCE | Huntsman Advanced Materials.

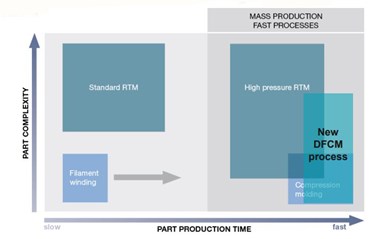

Huntsman Advanced Materials (Basel, Switzerland), however, has not only developed epoxy resins for wet compression molding, but claims to have advanced the process to achieve production cycles of less than 90 seconds for parts with complex geometry (medium draw or >2.5D).

Termed Dynamic Fluid Compression Molding (DFCM), it is described as a lowpressure process (typically 30 bar) offering highly structural parts made with fast-cure Araldite epoxy resin, and often removes the need for a preform. DFCM reportedly can achieve fiber volume of up to 65% in a low-waste process that produces void-free parts for high mechanical performance. It also claims lower equipment investment vs. HP-RTM and elimination of racetracking and fiber wash issues.

Thermoplastics

Thanks to Arkema's (Colombes, France and King of Prussia, PA, US) Elium resins, wet compression molding may also be extended to thermoplastics. The liquid acrylic thermoplastic resins reportedly can be used in wet compression molding or cold press molding at temperatures ranging from 20°C to 80°C to make recyclable composite parts in a very efficient way. Arkema claims a variety of reinforcements can be used, as well as functional fillers to impart additional properties to the composite part. This material and process combination also touts 30-50% weight reduction vs. steel parts with the same resistance and lower part manufacturing costs vs. other thermoplastic technologies.

Related Content

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)