Wind blades: Pi preforms increase shear web failure load

Easily coinfused structural joint increases ultimate strength and fatigue life, offering solutions for designers as blades get longer and move offshore.

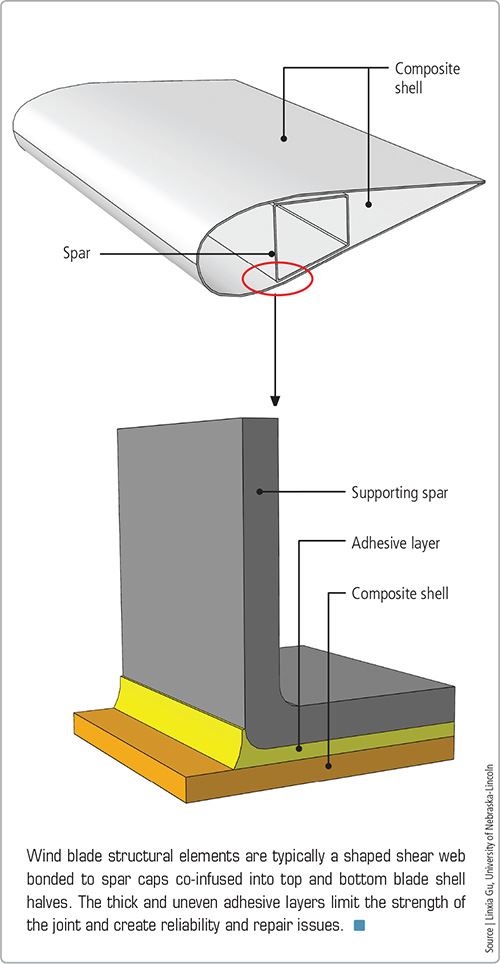

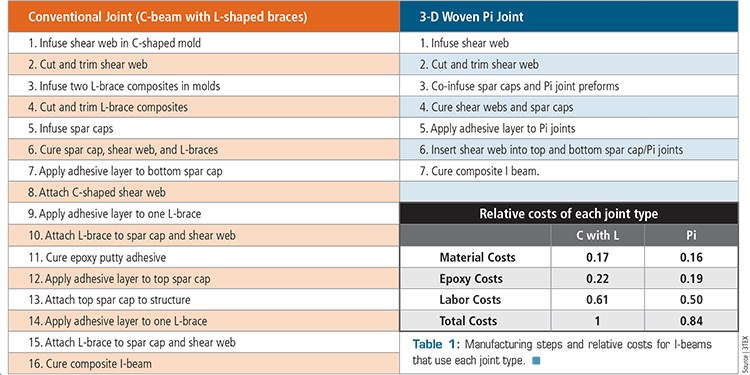

Wind blades are commonly made by infusing top and bottom blade shells separately, then adhesively bonding them together around a prefabricated shear web. The current state of the art leaves much to be desired. The typical construction is essentially an I-beam, in which a C-shaped shear web provides an area for adhesive bonding to spar caps that are co-infused with the blade shell. Typically, the C-beam must be braced with additional L-beams during assembly (see left side of the illustration in the second image from top). After epoxy paste adhesive is applied to the bottom blade half and the shear web, their surfaces are mated, and sufficient time must be allowed for cure. Then, adhesive is applied to the top blade half, the upper surface of the shear web and the leading and trailing edges. Again, the adhesive surfaces are mated, and time is required for cure. This multistep process requires significant labor and time. Additionally, when the top half of the blade is lowered onto the bottom half, the joints are mated blindly, that is, without visual or other access to the bonding areas. Industry presentations and patents list other shortcomings and clearly state that blade designs would benefit from an improved bond configuration between the shear web and spar cap.

Textile manufacturer 3TEX (Cary, N.C.) began work on such a configuration several years ago as part of a Small Business Innovation Research (SBIR) project awarded by the U.S. Department of Energy (DoE, Washington, D.C.), using the Pi joint concept that was demonstrated in the Air Force Research Lab’s (AFRL, Dayton, Ohio) Composites Affordability Initiative (see “The Composites Affordability Initiative, Part I” under "Editor's Picks," at top right).

Why Pi?

3TEX cites two reasons for its use. First, the Pi joint (so named because its primary component takes the shape of the Greek letter π) have been shown in the aerospace industry to provide superior strength in pull-test loads, compared to conventional laminated joints. AFRL’s Dr. John Russell says the joint “provides symmetrical loads to the adhesive area and acts as a double lap-shear joint, increasing the surface area for bonding.” Also, the primary load in the adhesive bonds is located farther away from the area of maximum strain. These factors combine, says Russell, to make the Pi joint a more effective design. Pi joints also have demonstrated high tolerance of several manufacturing defects associated with blind mating, including excessively thick bondlines, voids, nonvertical alignment of the Pi legs or joint structure within the Pi, and even peel plies that are not removed before bonding.

Second, a Pi joint, despite its complexity, can be preformed in an automated process. 3TEX R&D director Dr. Keith Sharp says his company’s 3D Weaving process “lends itself to easy manufacture of Pi joint preforms. We simply design a textile with z-direction yarns penetrating completely through the thickness for the center portion and then only halfway through the thickness for the outer edges, allowing these lengths to be folded up to form the two legs of the Pi.” The dry preform is reportedly easy to co-infuse with the blade shell so the legs of the Pi align vertically to receive and locate the shear web. This permits the blade manufacturer to use a simple flat plate for the web — C-shapes and L-braces are no longer necessary. Therefore, blind mating of the joint surfaces is vastly simplified.

Pi progress

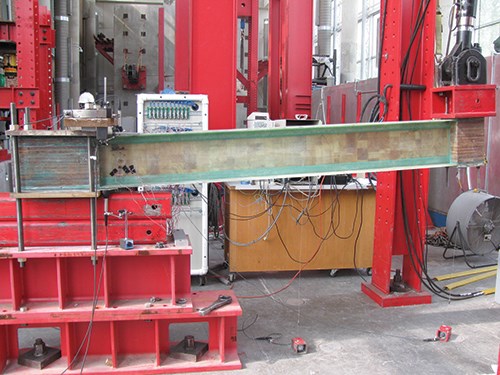

In a presentation at the 2012 SAMPE conference in Baltimore, Md., 3TEX reported that preliminary performance testing was done by fabricating composite I-beams made with the 3TEX 3-D woven Pi preform joint and a conventional joint (C-beam plus L-shaped braces, see top images, this page). The I-beams were 2.7m/8.9-ft long by 0.3m/1-ft tall, with 0.2m/0.7-ft wide flanges, matching the dimensions of the spar cap width and thickness and the shear web height of a 13m/42.7-ft long commercial wind blade at the 10m/33-ft station. The flanges were 8.1-mm/0.3-inch thick E-glass/epoxy laminate. A test apparatus was developed that clamped a standard I-beam at one end and applied an upward load at the other end to simulate the dominant type of loading on a wind blade.

For the Pi joint I-beams, Pi preforms were woven as a single E-glass fabric and split to form two 4.2-mm/0.2-inch thick legs, each measuring 42.5 mm/1.7 inches in length and separated by an 8.1-mm/0.3-inch thick central section that was 25-mm/1-inch wide. The 110-mm/4.3-inch wide preform had 54 percent total fiber volume fraction with equal amounts of fiber in both in-plane directions and 1.5 percent in the z-direction. A 20-mm/0.8-inch wide flat plate shear web was made, using 3.8-mm/0.2-inch thick faceskins of triaxial E-glass fabric from SAERTEX USA LLC (Huntersville, N.C.) on each side of a 12.4-mm/0.5-inch thick balsa wood core, supplied by distributor LBI Inc. (Groton, Conn.). The Pi joints and web were infused with Rhino 1401-21/4101-21 epoxy resin supplied by Rhino Linings (San Diego, Calif.). When the Pi joints and web were bonded, the Pi joint slot was 2.5 mm/1 inch wider than the web to allow sufficient space for the Rhino 405 Structural Epoxy Gel adhesive.

The conventional I-beam used in the test replicated the construction of a 13m/43-ft long commercial wind blade from Heartland Energy Solutions (Mount Ayr, Iowa). The C-shape shear web was made with two faceskins of triaxial E-glass fabric (0˚/±45˚ with 0˚ oriented along the beam length), each measuring 3.8-mm/0.15-inch thick, on each side of a 12.4-mm/0.5-inch thick balsa wood core. The material suppliers and infusion process were the same as those previously described. The top and bottom flanges of the C-beam were formed by extending the two faceskins at 90o to the cored section. The C-beam measured 7.6-mm/0.3-inch thick, and its height was 50 mm/1.97 inches. Two 7.2-mm/0.28-inch thick L-beams were adhesively bonded to bolster the C-beam. Spacers held the bondline thickness to 3 mm, ±0.3 mm (0.1 inch, ±0.01 inch).

Sharp says three conventional joint beams and five Pi joint beams were tested at the Constructed Facilities Laboratory at North Carolina State University (Raleigh, N.C.). The Pi joint beams failed at an average 12 percent higher load and 20 percent higher deflection than the conventional beams. That differed slightly from SAMPE paper data: “Those results included only three of the Pi joint tests and one of those underwent hysteresis loading. When we tested additional Pi joint cantilever beams without the hysteresis loading, the averages increased for both load and deflection at failure.”

Notably, the failure in the Pi joint beams resulted from buckling in the shear web, not failure in the Pi joint. The buckling forced the vertical legs of the Pi joint outward and, in turn, caused failure in the adhesive layer. Sharp asserts that increasing the shear web’s buckling resistance would likely produce an even higher failure load. However, this is not the case for the conventional joint beams, in which failure occurred within the adhesive layer first without any onset of buckling. Not least, the Pi joint beams also cost approximately 15 percent less to produce (see Table 1, last image). Sharp sums up, “Manufacture using co-infused 3-D woven Pi joint preforms requires fewer steps, less fiber, less resin and less adhesive than conventional joint manufacturing.”

Testing was extended to commercial-type construction of 13m blades. One blade with each joint type was tested under static load. Another pair was fatigue tested. Under static load the Pi-jointed blade failed at a 20 percent higher load and 25 percent greater deflection than the conventional blade. Even more dramatic were the results of fatigue tests. The test cyclically loaded the blades to 100 percent of the test load (design load plus a factor) for 1 million cycles, then it increased the load by 20 percent for each 200,000 cycles until failure. The blade with the conventional joint failed during the 160 percent load step after 1.45 million cycles. The Pi joint blade surpassed this, withstanding more than 700,000 cycles at the 180 percent load step; it failed after a total of 2.5 million cycles.

Pi potential

Sharp believes the 3TEX-tested Pi joint design could reduce the weight, cost and need for repairs in wind blades. “By increasing the ultimate strength and fatigue life, this type of joint should permit designers to reduce the material in the loaded sections of the blade, lowering material and manufacturing costs.” Indeed, 80m to 100m (262-ft to 328-ft) long blades now under development for offshore turbines might soon benefit from Pi joints (click on “Blade Dynamics receives investment for new wind blade design,” under “Editor's Picks").

Further, integrating Pi joints into blade construction methods appears to be a solution because increasing blade lengths tests the limits of current bond technology. During their discussion of design drivers and expected failure modes in future longer blades at the 2012 Sandia Wind Turbine Workshop (May 31-June 1, Sandia National Laboratories, Albuquerque, N.M.), representatives of Bladena (Ringsted, Denmark) pointed out that when the blade length surpasses 60m/197 ft, fatigue failure in the bondlines and failure of the shear web become a critical failure mode, a reality that could be addressed with Pi joints. Bladena, a commercial spin-off of wind energy research institute Risø DTU (Roskilde County, Denmark), also observed a nonlinear crushing pressure phenomenon that increases in longer blades because they bend more. The Pi-jointed beams in the test blades exhibited increased stiffness, which would counter the crushing pressure. Finally, Bladena identified interlaminar failure in the load-carrying spar caps and shear web flanges as a risk that increases with blade length. Orthogonally woven 3-D textiles are inherently resistant to delamination. Thus, they could improve performance not only in the shear web-to-blade shell joint but also in the spar cap. Therefore, Sharp believes Pi joint preforms could provide benefits elsewhere, especially in very large composite structures, such as those in ships.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreSmartValves offer improvements over traditional vacuum bag ports

Developed to resolve tilting and close-off issues, SmartValves eliminate cutting through vacuum bags while offering reduced process time and maintenance.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

Market Trends: The Composites Affordability Initiative, Part I

The Air Force Research Laboratory's Dr. John Russell outlines the U.S. Department of Defense Composites Affordability Initiative. Part I of a two-part series.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)